Composite reactive red dye

A technology of reactive red dyes and dyes, applied in organic dyes, dyeing methods, textiles and papermaking, etc., can solve the problems of high color flower rate, asynchronous dyeing time, poor color reproducibility, etc., and achieve stable performance and deep dyeing The effect of outstanding color and high color fixing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

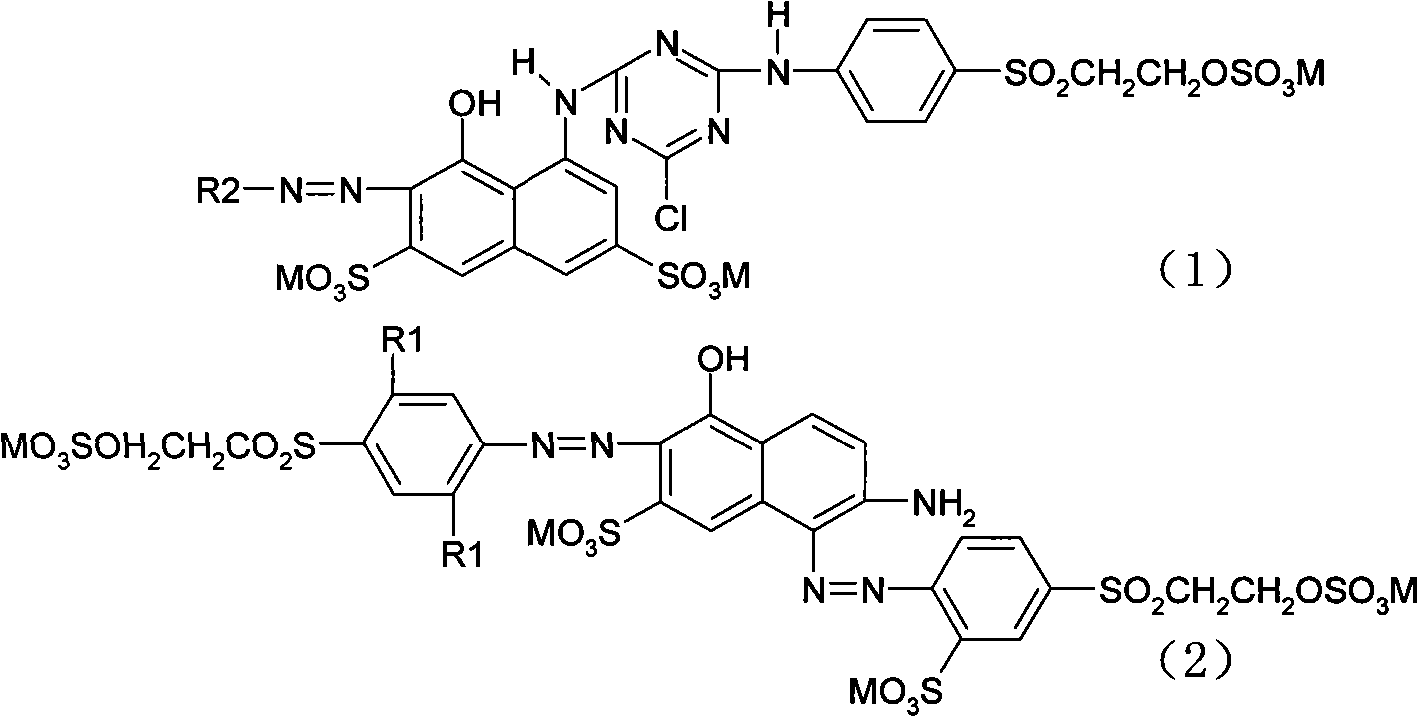

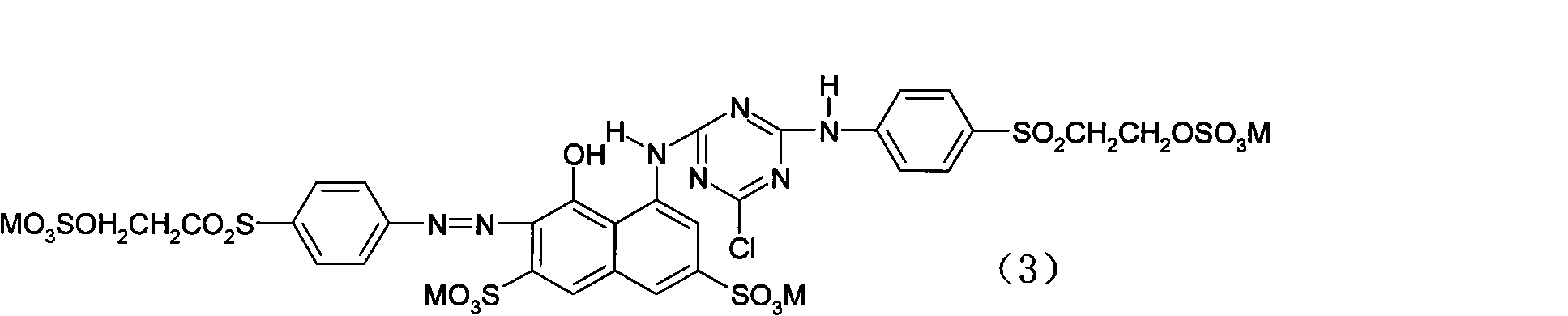

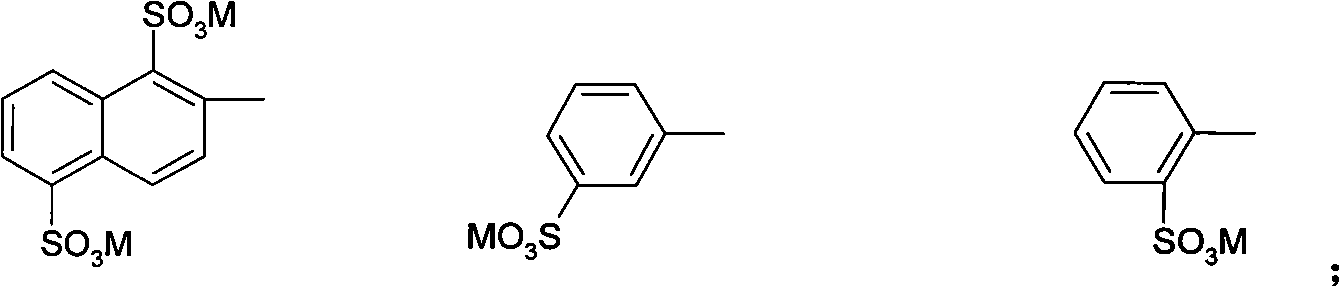

Method used

Image

Examples

Embodiment 1

[0037] 50g conforms to formula (1) dyestuff (1-1), 20g conforms to formula (2) dyestuff (2-1) and 30g conforms to formula (3) dyestuff and obtains composite reactive red dyestuff of the present invention through fully mechanical mixing, this The dye can print and dye the cellulose fiber material into red with deep color, good level dyeing, good reproducibility and good color fastness.

[0038]

Embodiment 2

[0040] Mix the aqueous solution containing 50g formula (1) dye (1-1), the aqueous solution containing 20g formula (2) dye (2-1) and the aqueous solution containing 30g formula (3) dye, stir evenly and dry, obtain the present invention Composite reactive red dye, this dye can print and dye cellulose fiber materials into red with deep color, good level dyeing, good reproducibility and good color fastness.

Embodiment 3

[0042] 80g conforms to formula (1) dyestuff (1-2), 10g conforms to formula (2) dyestuff (2-2) and 10g conforms to formula (3) dyestuff and obtains composite active red dyestuff of the present invention through fully mechanical mixing, this The dye can print and dye the cellulose fiber material into a red color with deep color, good level dyeing, good reproducibility and good color fastness.

[0043]

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com