Superconducting fluid and vacuum radiator using same

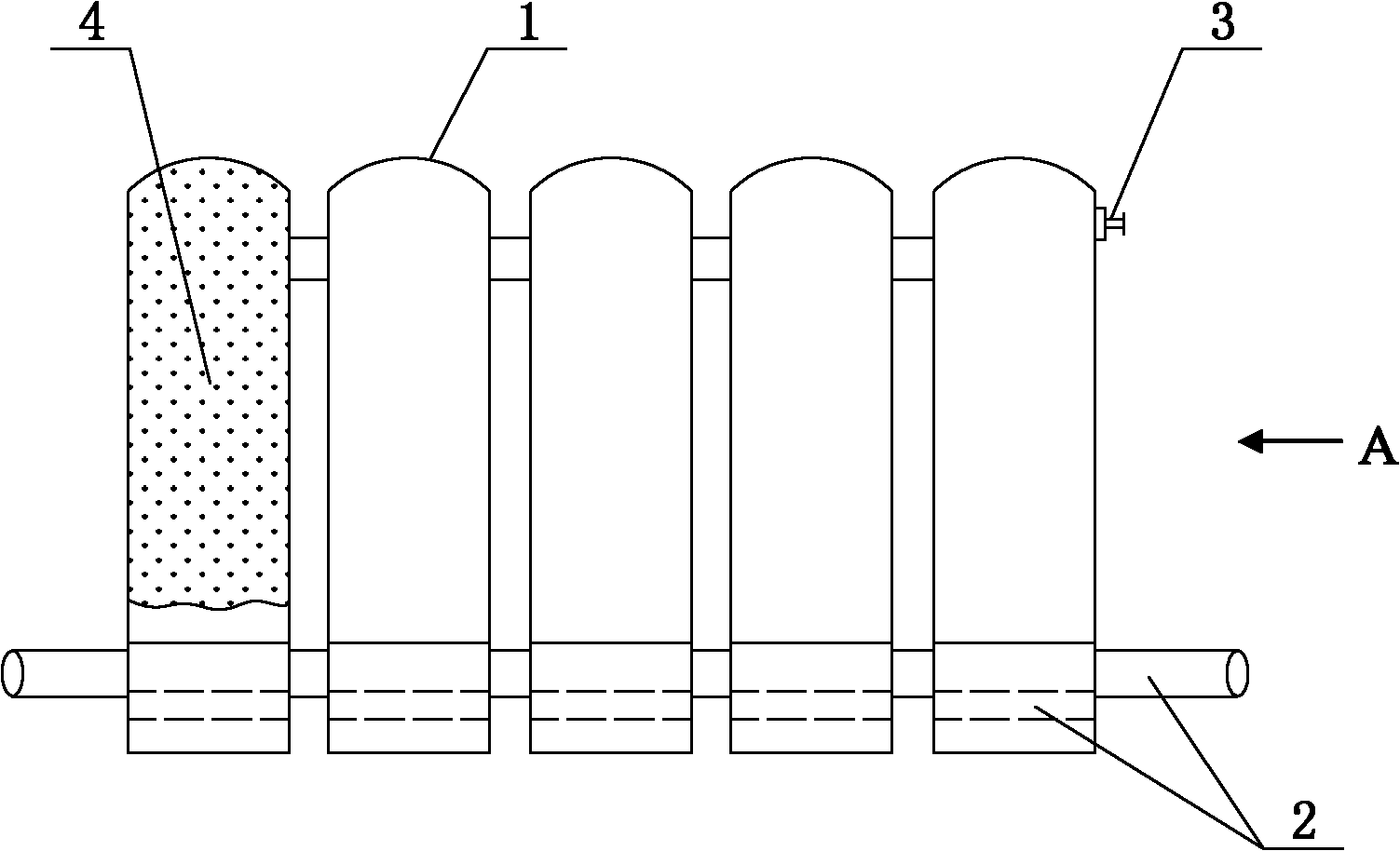

A technology of superconducting liquid and heat sink, applied in indirect heat exchangers, heat exchange materials, chemical instruments and methods, etc., can solve the problems of inability to meet heating requirements, unfavorable use in alpine regions, and inability of superconducting liquid to rise, etc. To achieve the effect of saving the amount of heat medium, good heat release effect, and saving the number of columns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

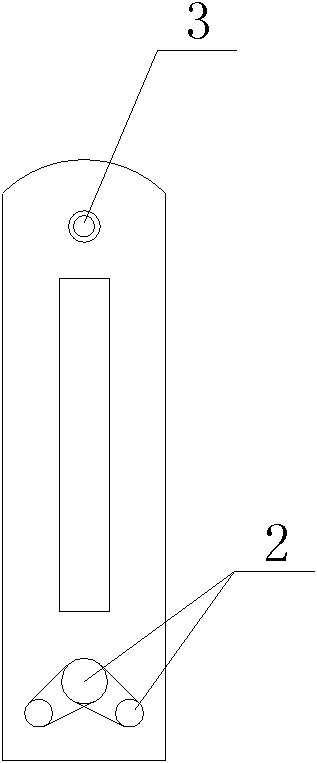

Method used

Image

Examples

preparation example Construction

[0027] The preparation process of the superconducting liquid is as follows: first mix 2.6%-3.2% potassium dichromate and 0.3%-0.5% calcium chloride and react for 5 minutes, then add 4.8%-7% absolute ethanol and react for 7 minutes, then add 0.5%-0.7% sodium perborate and 0.1%-0.3% boric acid reacted for 2 minutes, then added 0.04%-0.1% manganese dioxide, 0.08%-0.16% sodium peroxide, 0.06%-0.1% zinc hydroxide and reacted for 10 minutes , and finally, the remainder is supplemented by ionized water with a resistivity of 1.5MΩ·m or more, and the mixture is evenly stirred.

[0028] The superconducting liquid provided by the invention is inorganic, non-toxic to human body, non-combustible, non-freezing at -40°C, vaporized at 40°C, and non-corrosive to metals.

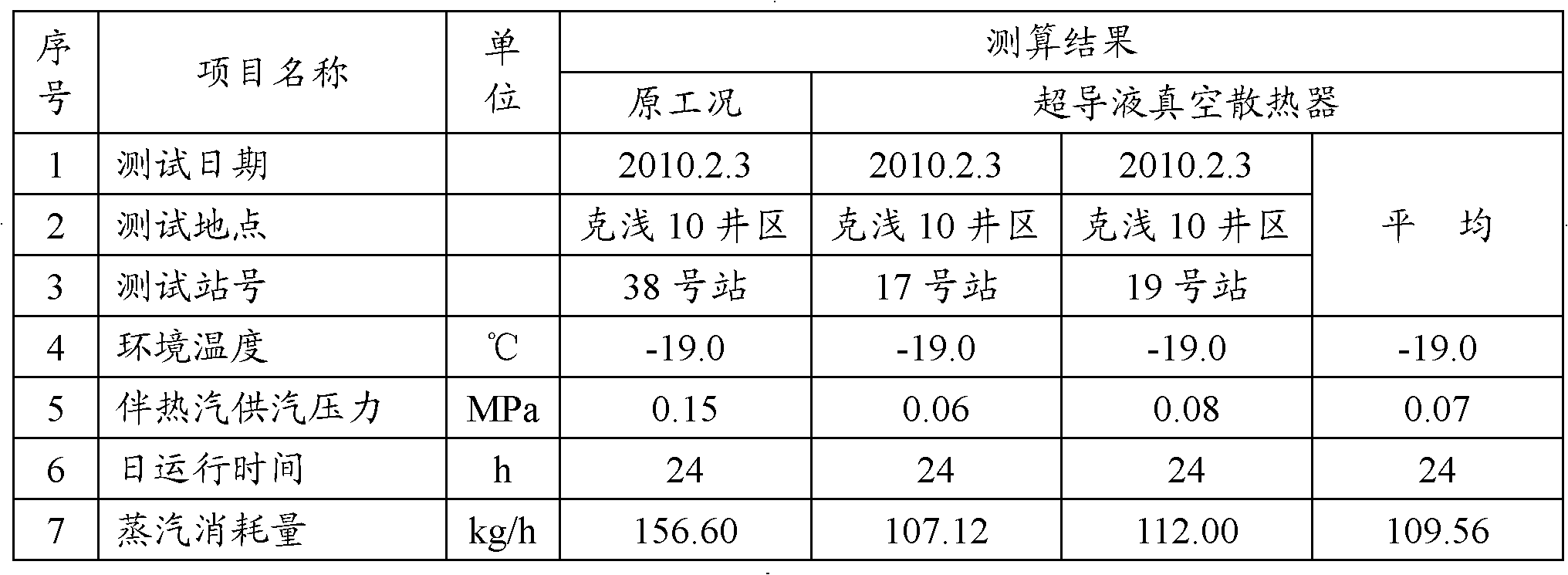

[0029] As shown in Table 1 and Table 2, compared with water, the thermal conductivity of the superconducting liquid provided by the present invention is significantly higher than that of water, and the specific heat capacity ...

Embodiment 1

[0036] Mix 2.7% potassium dichromate and 0.4% calcium chloride and react for 5 minutes, then add 7% absolute ethanol and react for 7 minutes, then add 0.5% sodium perborate and 0.12% boric acid for 2 minutes, then add 0.09% dichromate Manganese oxide, 0.1% sodium peroxide, and 0.08% zinc hydroxide were reacted for 10 minutes, and finally 89.01% of ionized water with a resistivity of 1.5MΩ·m or more was added.

Embodiment 2

[0038] Mix 2.6% potassium dichromate and 0.3% calcium chloride and react for 5 minutes, then add 5.9% absolute ethanol and react for 7 minutes, then add 0.6% sodium perborate and 0.1% boric acid for 2 minutes, then add 0.04% dichromate Manganese oxide, 0.08% sodium peroxide, and 0.06% zinc hydroxide were reacted for 10 minutes, and finally 90.32% ionized water with a resistivity of 1.5MΩ·m or more was added.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Average temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap