Active anti-shear concrete supporting structure for reinforcing deep sliding surfaces of rock slopes

A technology for supporting structures and rock slopes, which is applied in basic structure engineering, construction, excavation, etc., can solve problems such as failure of anchor holes, broken steel bars, and easy cracking of concrete, so as to improve bending resistance and anti-corrosion pull effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further introduced below in conjunction with specific embodiments of the present invention. Concrete realization process of the present invention is as follows:

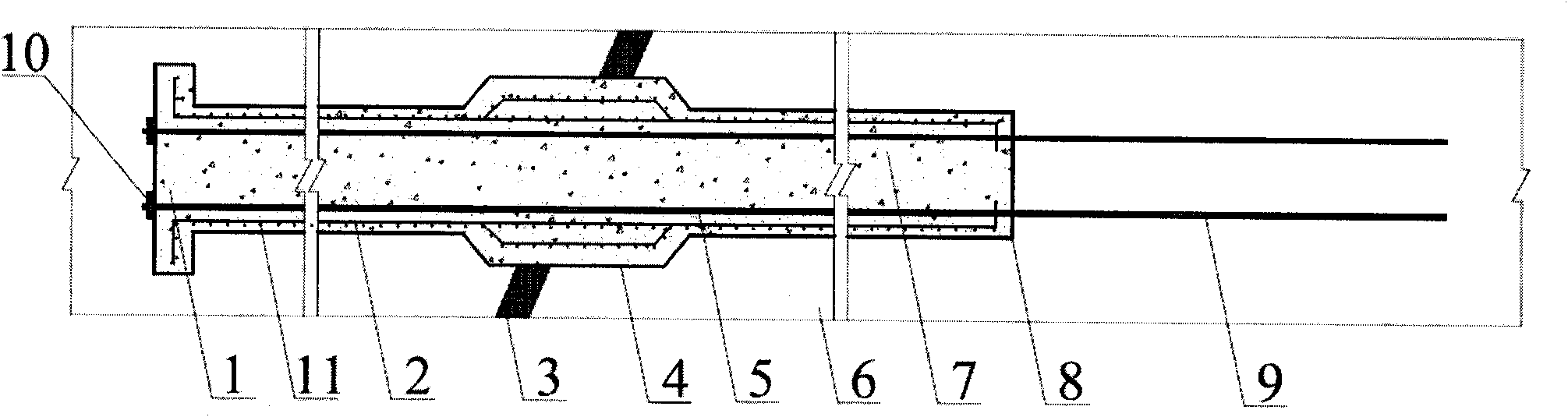

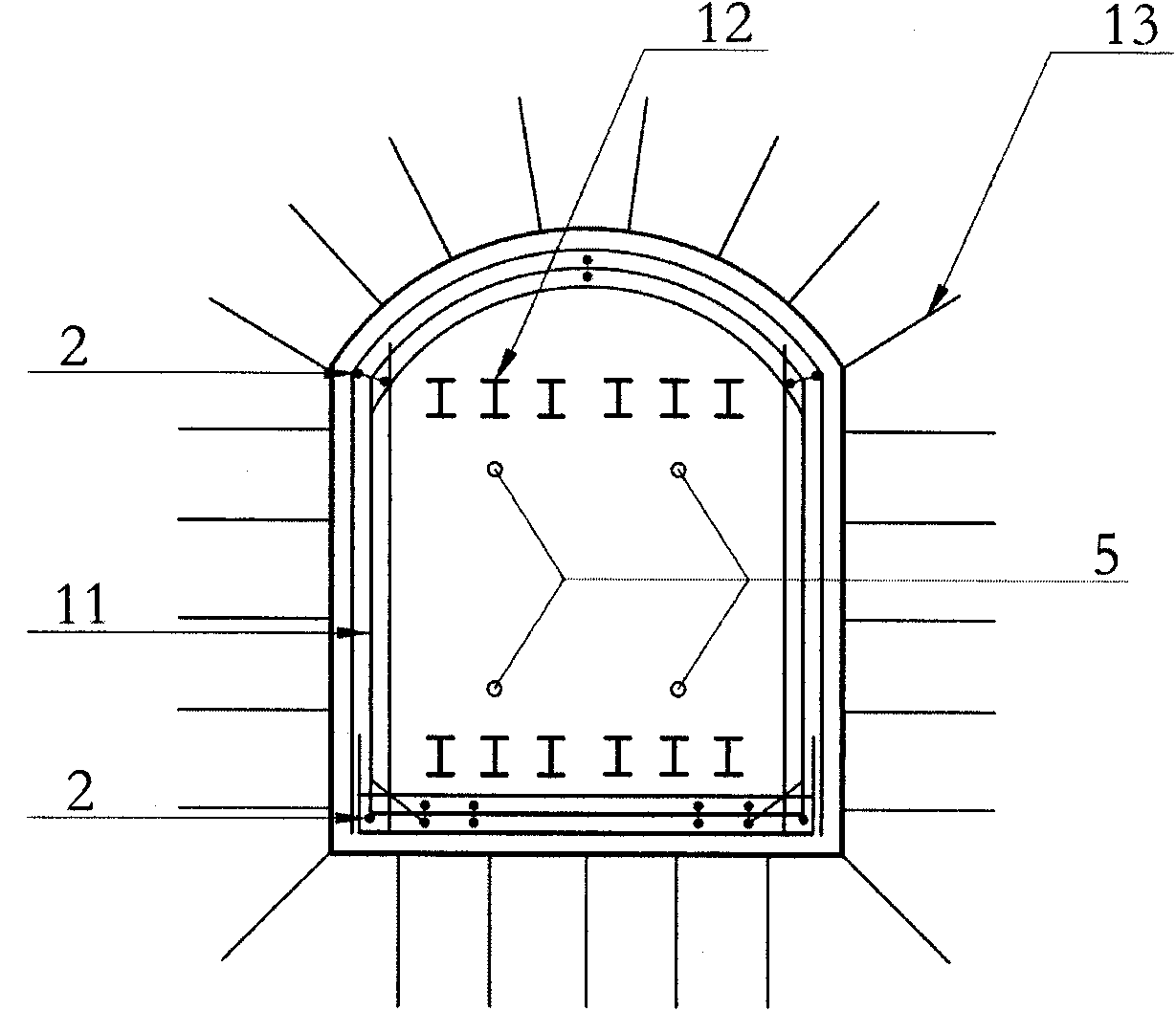

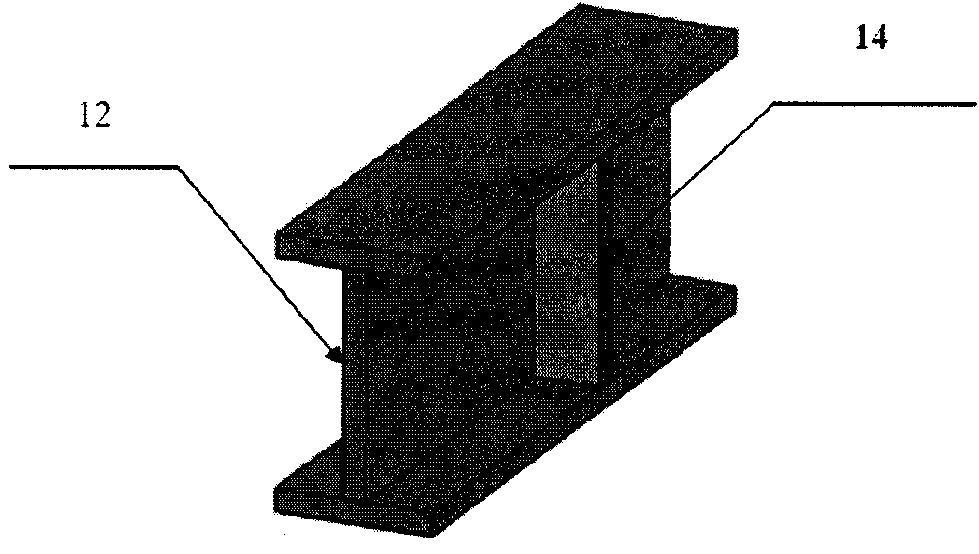

[0026] In rock slopes with deep slip surfaces, horizontal or near-horizontal strip-shaped anchor holes 8 are excavated vertically or nearly vertically to the slip surface, and the section is enlarged at the end of the anchor holes on the slip surface 1, and the length of the anchor hole on both sides of the sliding surface is not less than 1.5 to 2 times the hole diameter; during the excavation of the anchor hole, steel mesh and shotcrete are set as the initial support; Anchor cable holes are drilled from the top of the mountain, the axis direction of the anchor cable is parallel to the anchor hole, the depth of the drill hole is the design length of the anchor cable minus the axis length of the anchor hole, and the inner anchor section of the prestressed anchor cable 9 must be lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com