Electrical control device for piston methane slag and methane liquid discharging pump

A discharge pump and piston type technology, which is applied in the field of control devices, can solve the problems of blockage of the discharge pump of the biogas digester, and achieve the effect of convenient discharge, large flux and less failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

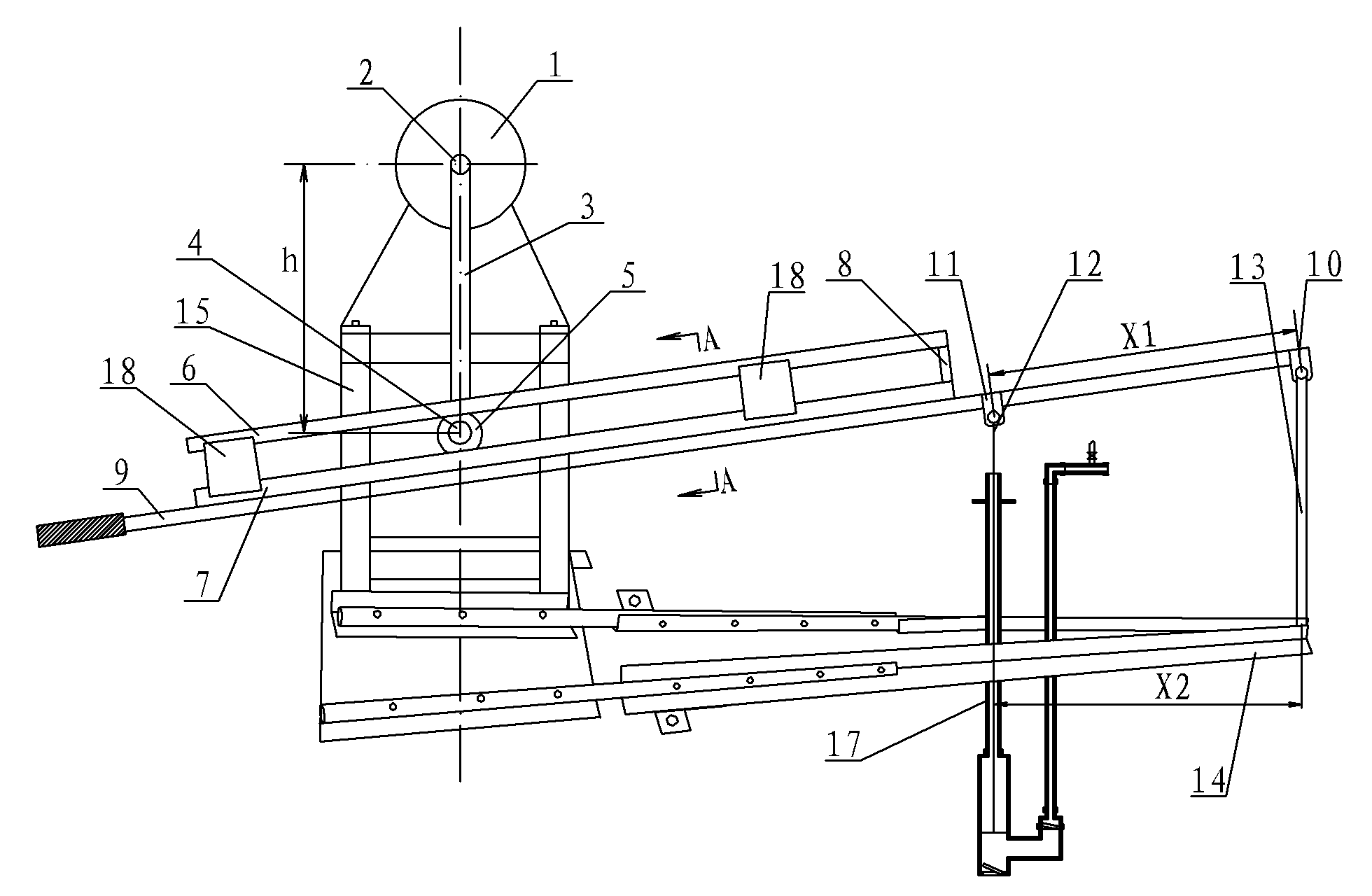

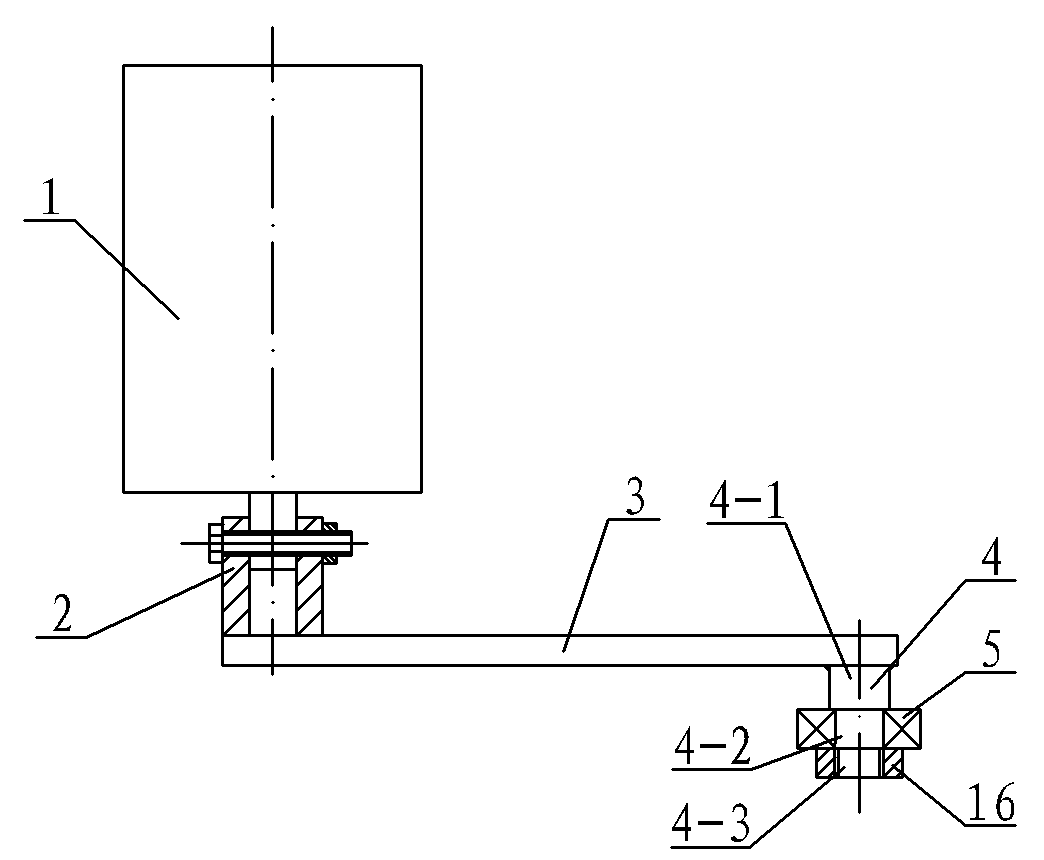

[0007] Specific implementation mode one: combine Figure 1 to Figure 4 Describe this embodiment, this embodiment includes motor 1, sleeve 2, rocker arm 3, crank 4, bearing 5, upper slide rail frame 6, glide rail frame 7, support plate 8, pressure handle 9, first hinge seat 10 , the second hinged seat 11, steel bar 12, pole 13, fixed frame 14, motor seat 15, lock nut 16 and at least two short channel steels 18, the motor 1 is fixed on the motor seat 15, the first hinged seat 10 and the second hinge seat 11 are sequentially installed on the press handle 9 along the direction from the front end to the rear end of the press handle 9, the distance X1 between the first hinge seat 10 and the second hinge seat 11 is 300 mm to 1000 mm, and the sleeve 2 is set on the On the output shaft of the motor 1, the sleeve 2 and the motor 1 are connected together by connecting elements, one end of the rocker arm 3 is fixedly connected to the sleeve 2, the other end of the rocker arm 3 is welded t...

specific Embodiment approach 2

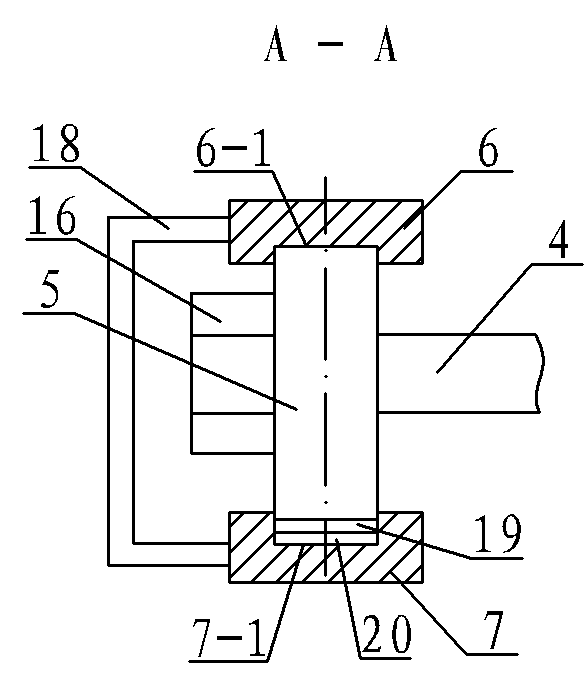

[0008] Specific implementation mode two: combination image 3 This embodiment is described. The difference between this embodiment and the first embodiment is that it also adds a gasket 19, and the gasket 19 is arranged in the glide path 7-1. The surface finish of the gasket 19 is high, and when the bearing 5 rolls on the smooth gasket 19, the frictional resistance is small. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination image 3 Describe this embodiment, the difference between this embodiment and specific embodiment one is that it also adds polyethylene foam 20, and polyethylene foam 20 is arranged in glideway 7-1, and is positioned at pad 19 and bottom surface of glideway 7-1 between. The polyethylene foam 20 plays the role of sound-absorbing. Other components and connections are the same as those in the second embodiment.

[0010] The working principle of the present invention: the sleeve 2 rotates under the drive of the motor 1, the sleeve 2 drives the rocker arm 3 to perform a circular motion around the output axis of the motor 1, the crank 4 and the bearing 5 move accordingly, when the bearing 5 rotates to the highest point, the piston in the discharge pump moves to the highest point, and when the bearing 5 turns to the lowest point, the piston in the discharge pump moves to the lowest point, and the bearing 5 rotates 360° around t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com