Linear electrostatic sensor array method for measuring particle speed and device thereof

An electrostatic sensor and particle velocity technology, applied in measuring devices, fluid velocity measurement, velocity/acceleration/impact measurement, etc., can solve the problems of reducing filter space selectivity, affecting the accuracy of velocity measurement, and large degree of dispersion. The signal processing is convenient, the structure is simple, and the effect of improving accuracy

Active Publication Date: 2010-12-01

SUZHOU HUAMAO ENERGY TECH

View PDF5 Cites 26 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the output signal frequency range of a single ring-shaped electrostatic sensor is wide, which reduces the spatial selectivity of the filter. On the power spectrum characteristic curve, it shows that each point has a large degree of dispersion, the peak is not obvious, and the signal-to-noise ratio is low, which affects the Accuracy of speed measurement

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

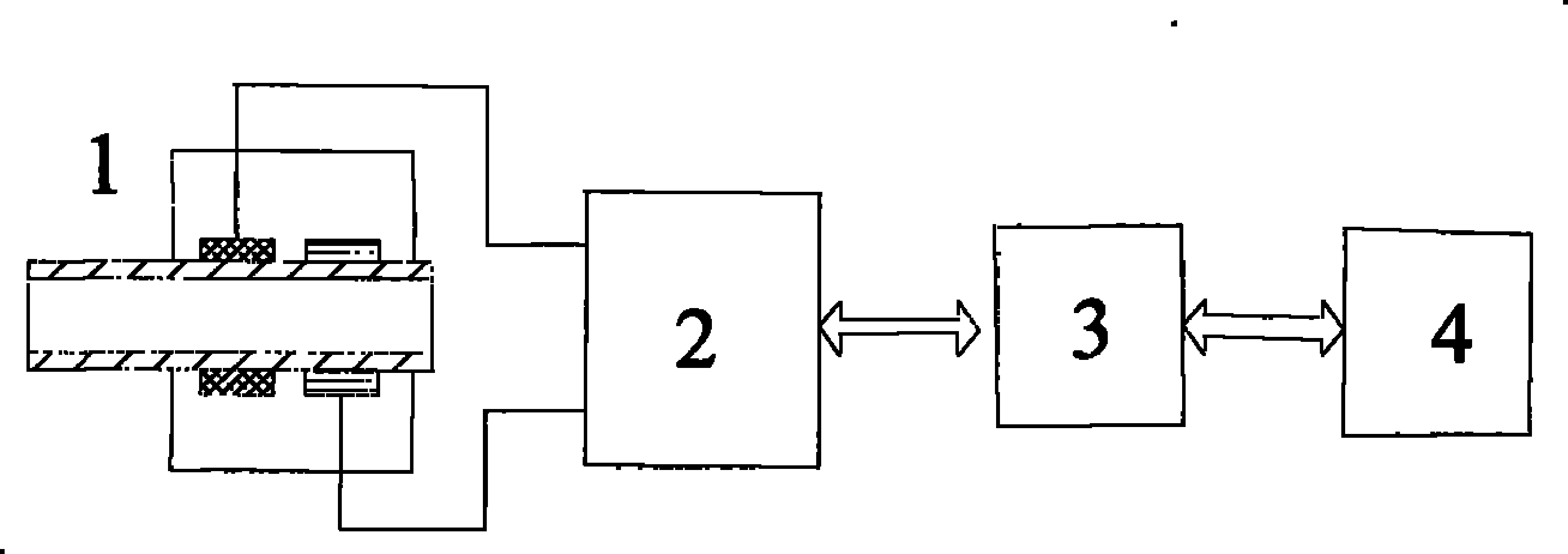

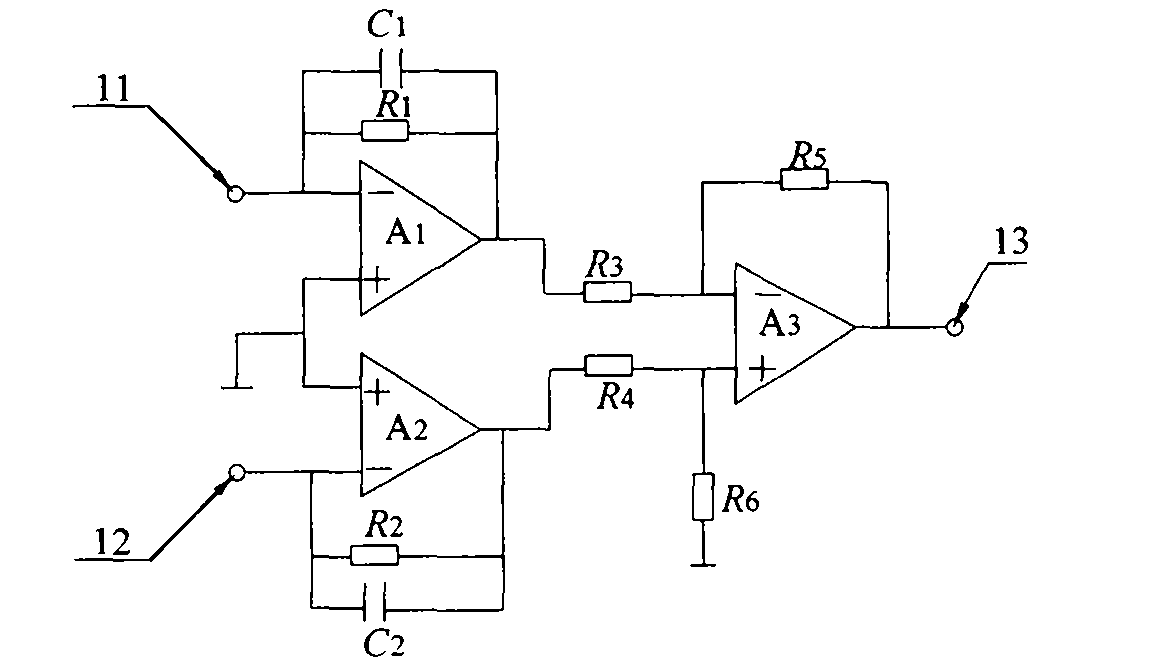

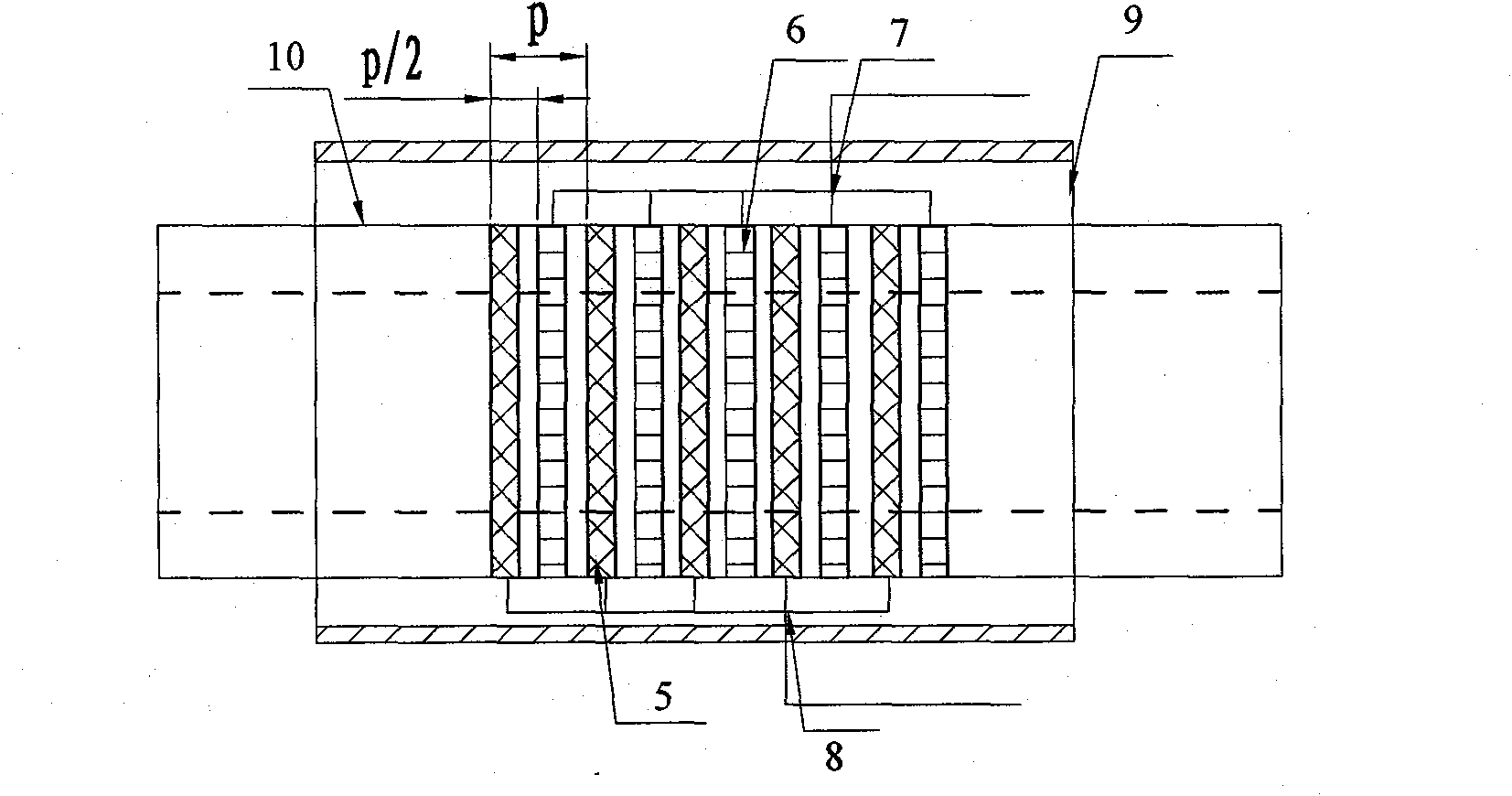

The invention discloses a linear electrostatic sensor array method for measuring particle speed and a device thereof. The method comprises the following steps: a duct is axially provided with a first linear electrostatic sensor array and a second linear electrostatic sensor array which are composed of a plurality of ring electrodes; when charged particles pass through the two electrostatic sensor arrays, two sets of electrostatic signals, which reflect gas-solid flow information, are generated; after the electrostatic signals are accessed into a front charge differential circuit to be amplified, a data acquisition circuit sends the amplified signals into a computer; and the computer carries out spectral analysis on the differential electrostatic signal and determines the peak frequency on the frequency spectrum, thereby obtaining the average speed of gas-solid two-phase flow particles. Compared with the single ring electrostatic induction spatial filter, the linear electrostatic sensor array has higher space selectivity, thereby enhancing the measurement accuracy of the particle speed. The device comprises a measuring probe, a front charge differential amplification circuit, a data acquisition card and a computer.

Description

Method and device for measuring particle velocity with linear electrostatic sensor array technical field The invention belongs to the technical field of gas-solid two-phase flow measurement, and in particular relates to a linear electrostatic sensor array measurement method and device for gas-solid two-phase flow particle velocity. Background technique Gas-solid two-phase flow systems are widely used in energy, chemical, electric power and metallurgy industries. Particle velocity is an important parameter to describe the gas-solid two-phase flow system. The measurement of particle velocity is of great significance for understanding the characteristics of gas-solid flow and the measurement, energy saving and control of the production process. The collision, friction and separation of particles and particles, particles and gas, and particles and pipe walls in the gas-solid flow system lead to the charging phenomenon of particles. In recent years, people have used particle c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01P5/08

Inventor 许传龙李健高鹤明付飞飞王式民

Owner SUZHOU HUAMAO ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com