Burn-up measurement system for spent fuel assembly

A measurement system and technology for spent fuel, used in nuclear reactor monitoring, reactors, nuclear power generation, etc., can solve the problems of long measurement device length, unsuitable installation and measurement, and no automatic control mechanical parts, etc., to achieve a compact measurement system and high measurement accuracy. Effect

Active Publication Date: 2010-12-01

CHINA INSTITUTE OF ATOMIC ENERGY

View PDF5 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the setting of the track for the CZT detector to move back and forth, the length of the entire measuring device is relatively long, and it is not suitable for random installation and measurement in the storage pool of densely packed spent fuel assemblies.

另外在美国2005年专利US6895065-B1、《GammaspectrometriccharacterizationofshortcoolingtimenuclearspentfuelsusinghemisphericCdZnTedetectors》(NuclearInstrumentsandMethodsinPhysicsResearchA448(2000)598-603)、《Spent-fuelcharacterizationwithsmallCZTdetectors》(NuclearInstrumentsandMethodsinPhysicsResearchA564(2006)290-294)中,法国A.Lebrun和意大利R.Berndt等人 Both have disclosed the use of CZT detectors to measure the counting rate of 134Cs and 137Cs to calculate the related technology of spent fuel burnup in the spent fuel pool, but there is no automatic control of mechanical components to achieve the best measurement conditions

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

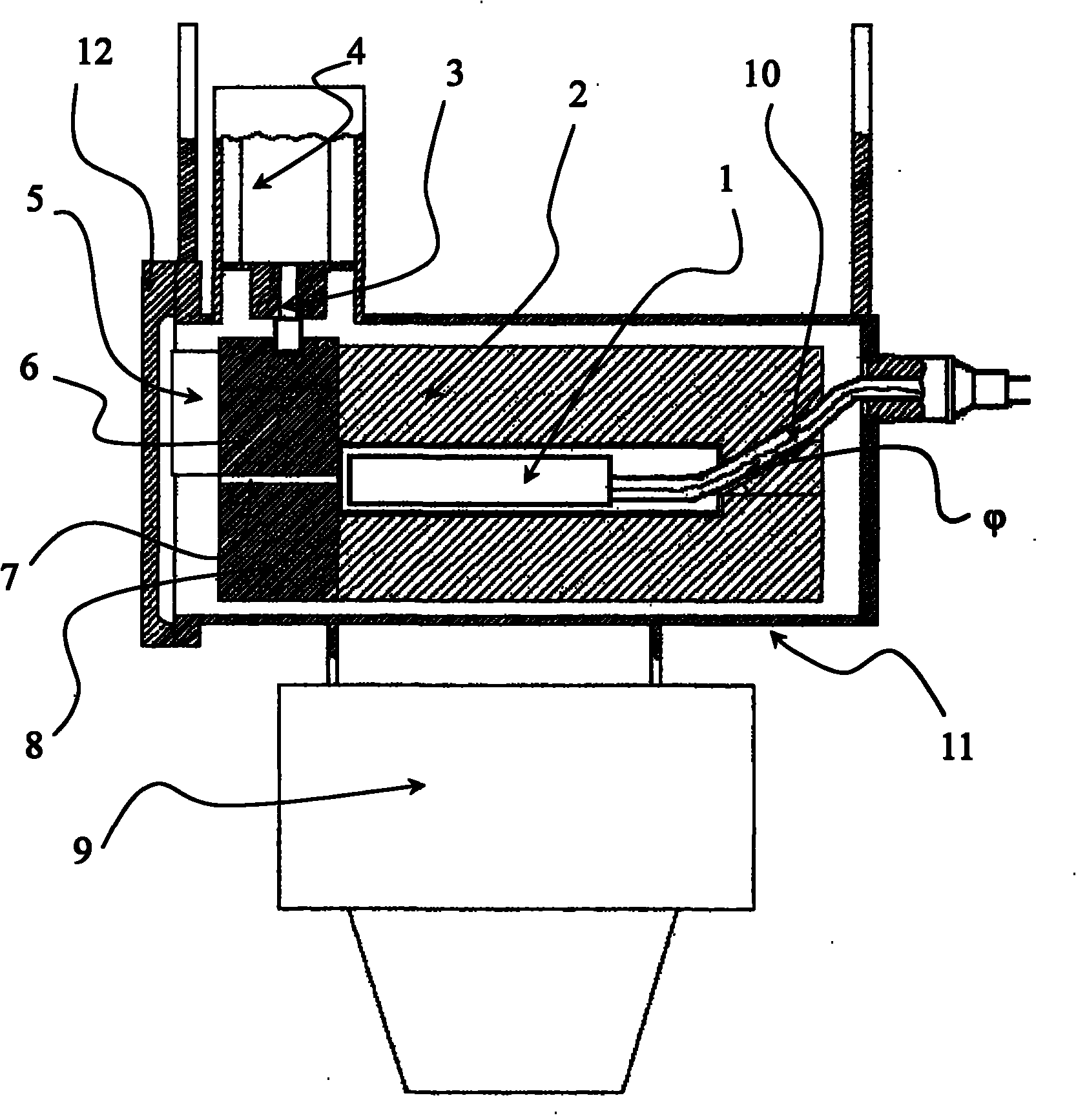

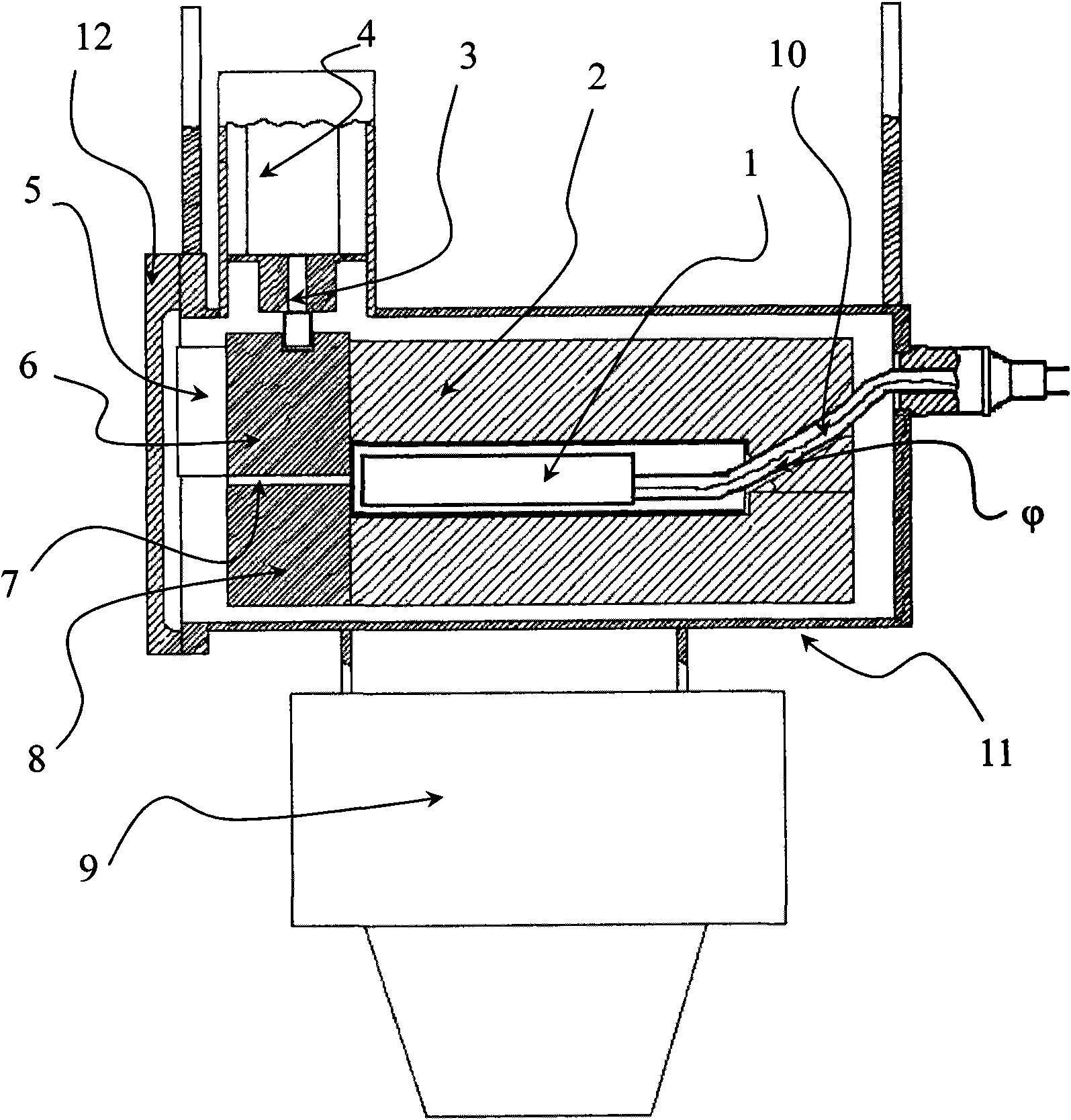

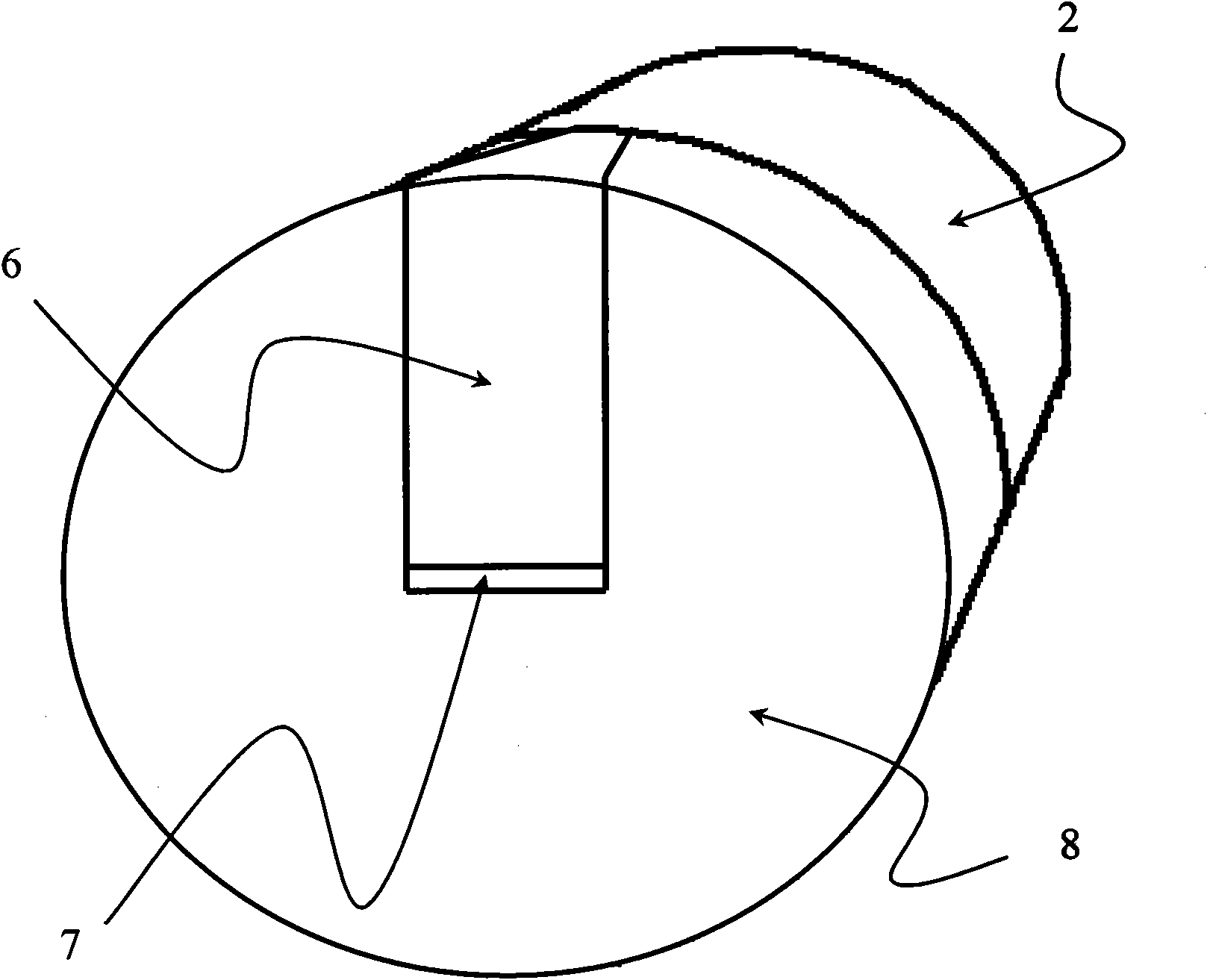

The invention discloses a gamma-spectrum detection system consisting of an antimony zinc cadmium detector and used for measuring burn-up of a spent fuel assembly. The system comprises a CZT detector, a digital multi-channel analyzer, a shielding aligner, a shield, a pressure-resistant sealing container and the like, wherein the shielding aligner is a cylinder; a conical groove is formed on an upper part of the shielding aligner; a movable slider is arranged in the conical groove; the movable slider is dragged by a step motor through a screw to move up and down; and the width of an alignment hole is controlled to be 0-5 mm. The system controls the width of the alignment hole by adjusting the movable slider so as to control a full-spectrum counting rate of a detected energy spectrum within a proper range and obtain relatively high measurement precision. Meanwhile, the measuring system is relatively compact and is favorable to be freely moved in a spent fuel assembly storage pool for in situ measurement.

Description

Spent Fuel Assembly Burnup Measurement System technical field The invention belongs to the technical field of gamma-ray radiation measurement, and in particular relates to a gamma spectrum detection system composed of antimony-zinc-cadmium detectors used for measuring the burn-up of spent fuel assemblies. Background technique The non-destructive measurement methods of spent fuel burnup mainly include Cherenkov glow detection, total gamma, high resolution gamma spectroscopy (HRGS), passive neutron and active neutron measurement, etc. The fork-shaped detector composed of passive neutron measurement and high-resolution HPGe gamma spectrometer can be used for burnup measurement of spent fuel, but usually requires a complex hardware system, and the collimation part of the front end of the HPGe detector often needs to be installed in the Inside the facility, if the system design is not done well in advance, it will be very difficult to retrofit later. Although the energy resol...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G21C17/06

CPCY02E30/30

Inventor 李建华

Owner CHINA INSTITUTE OF ATOMIC ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com