Switched reluctance motor for constructing magnetic circuit based on modularizing way

A switched reluctance and modular technology, applied in electrical components, electromechanical devices, etc., can solve the problems of small size of switched reluctance motors, inability to meet the requirements of traction motors, restricting the development trend of switched reluctance motors, etc. damage, and the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Further details will be given below in conjunction with the preferred embodiments shown in the accompanying drawings.

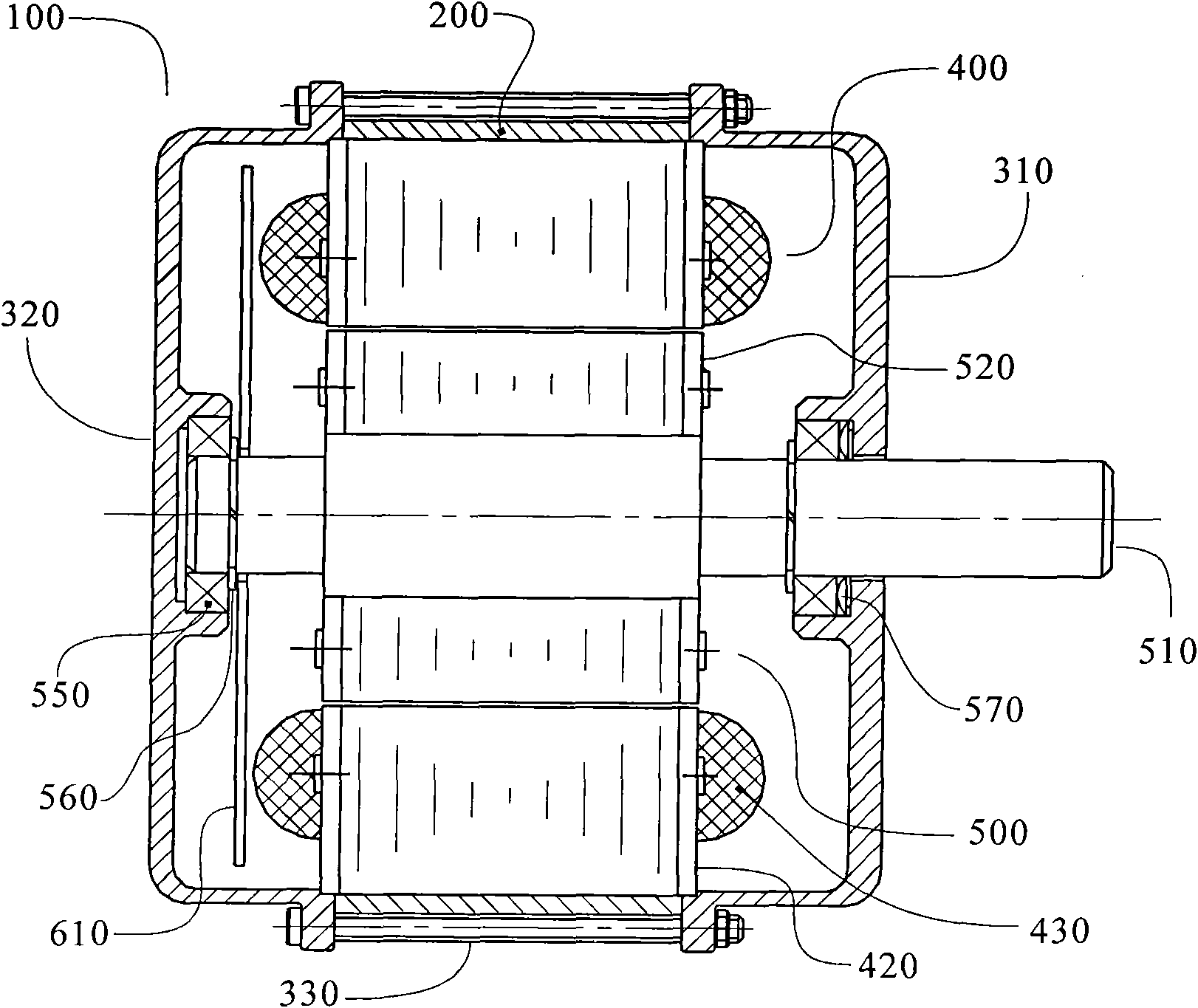

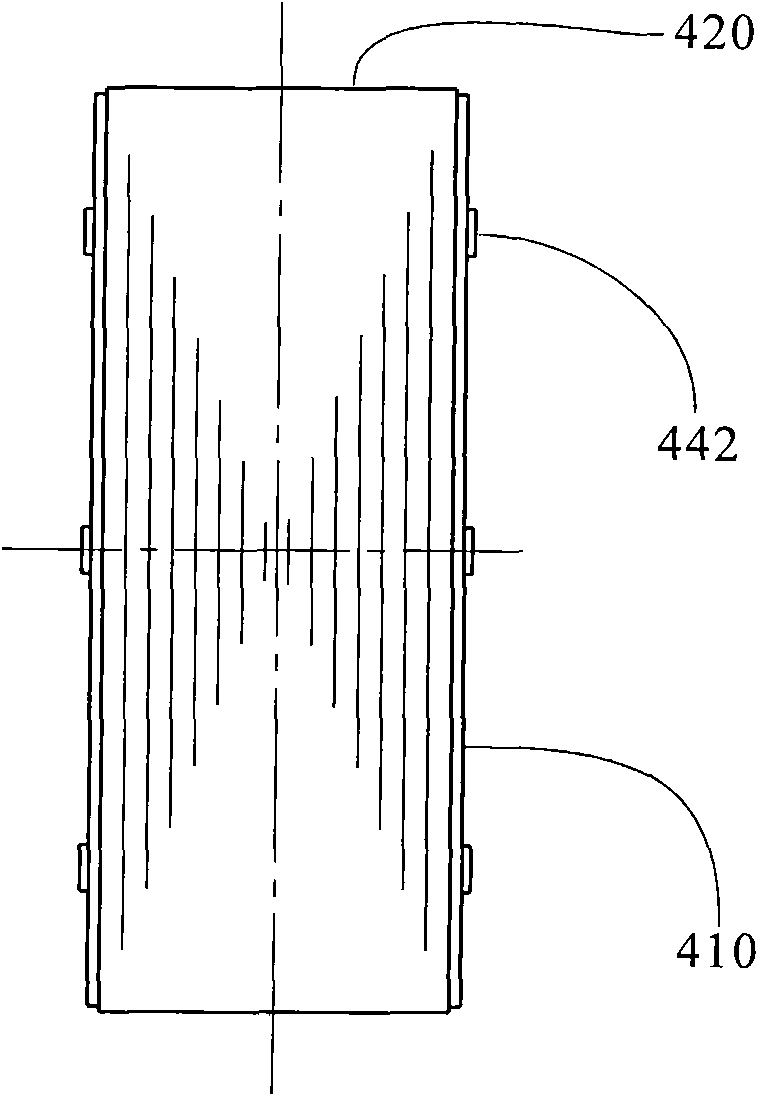

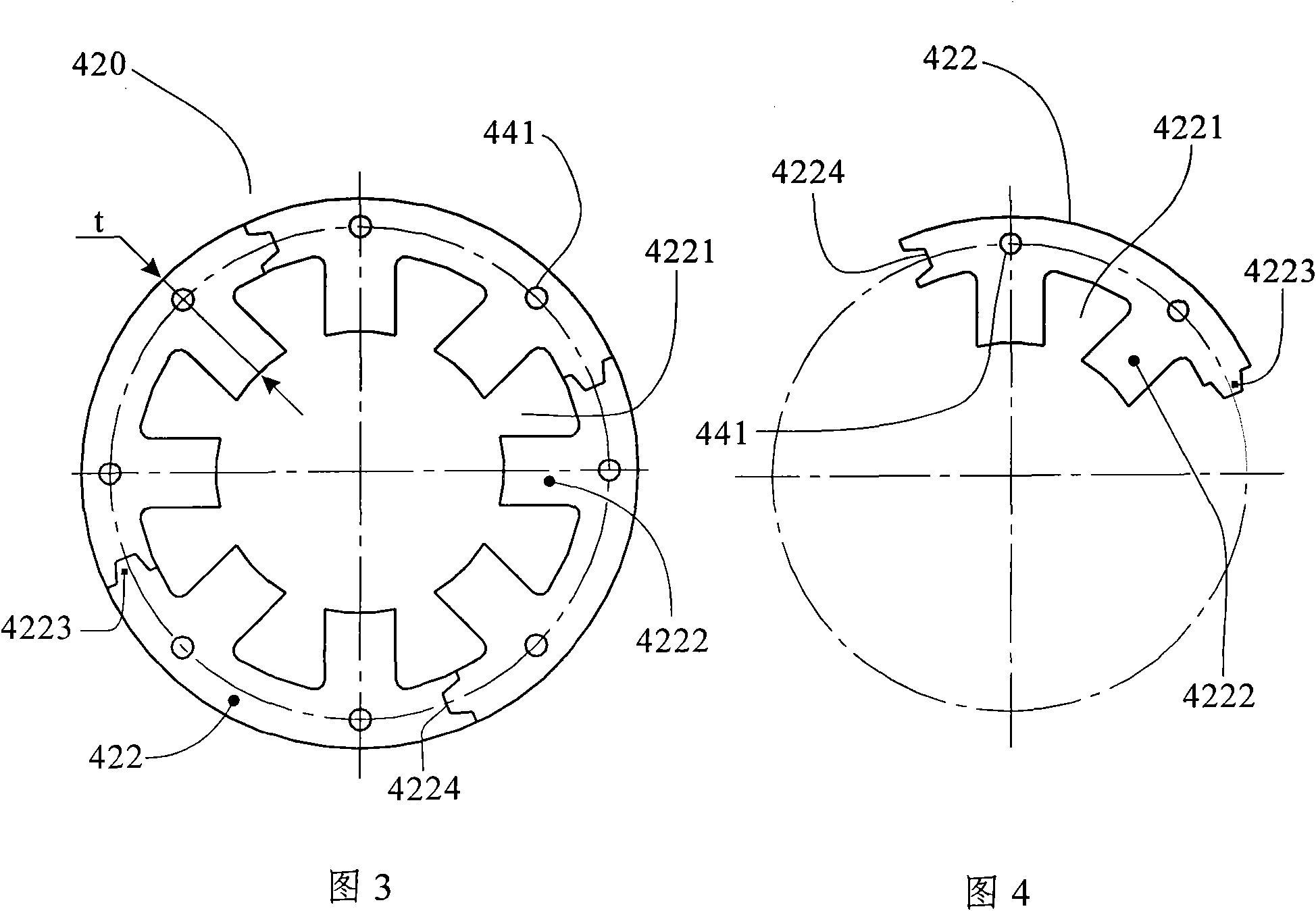

[0035] The present invention is based on a switched reluctance motor that constructs at least the stator magnetic circuit in a modular manner, such as figure 1 As shown, it includes a housing 200 , a front end cover 310 , a rear end cover 320 , a stator 400 with concentrated windings wound on each magnetic pole, and a rotor 500 with a salient pole structure. The magnetic circuit part 520 of the rotor 500 is tightly fitted or fixed on the motor shaft 510 by means of coupling keys, and each salient pole on the rotor magnetic circuit part 520 is not wound with any form of winding. The axial end of the stator 400 is provided with a rotor position sensor 600 . In particular, if Figure 2 to Figure 4 As shown, the iron core part 420 of the stator 400 includes N pieces of stator modules 422 connected with each other to form a circular cross-section cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com