Method of calibrating a constant voltage supply for an ultrasonic transducer of a wire bonding machine

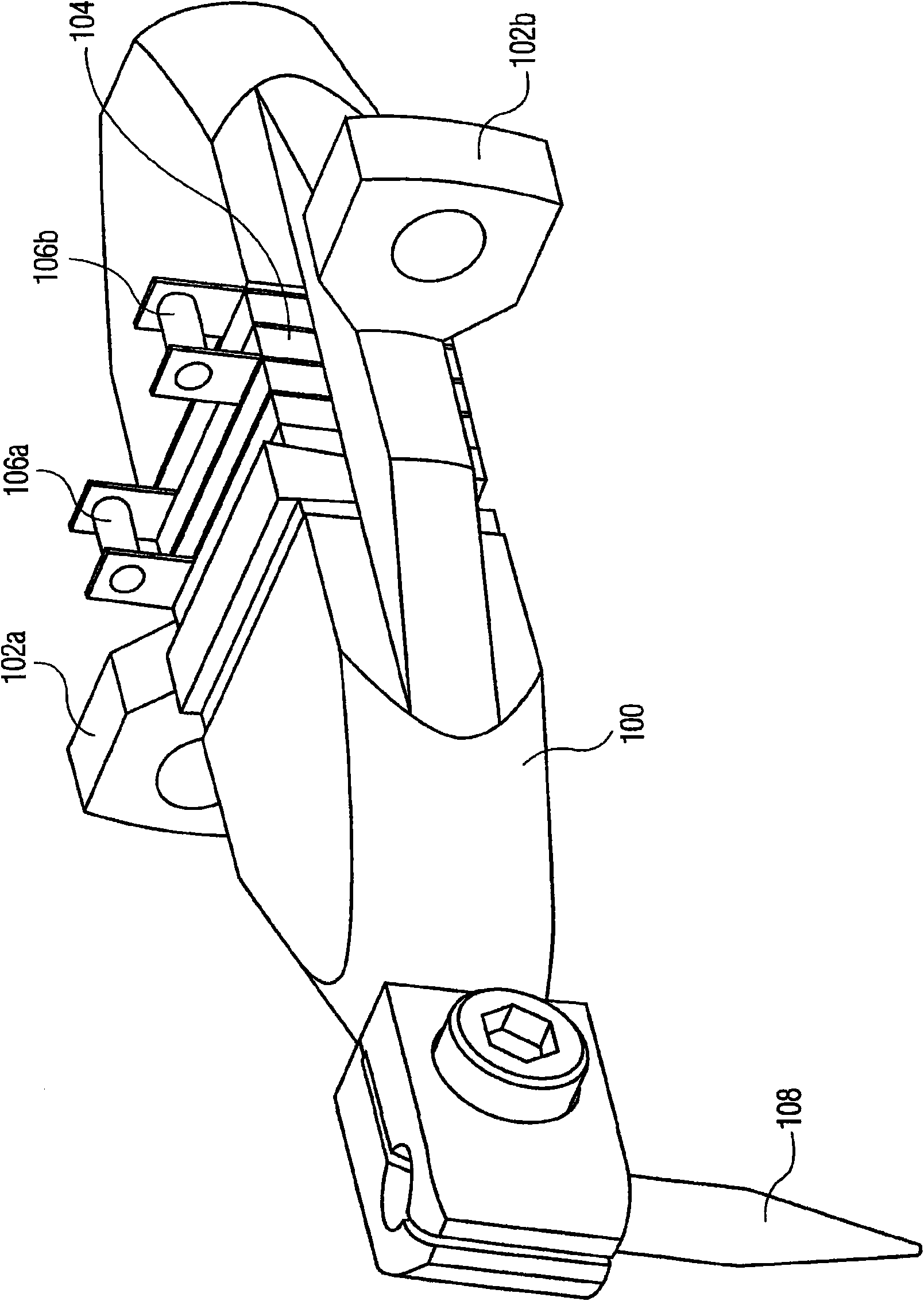

An ultrasonic transducer, wire bonding machine technology, applied in the direction of semiconductor devices, electric solid devices, fluids utilizing vibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

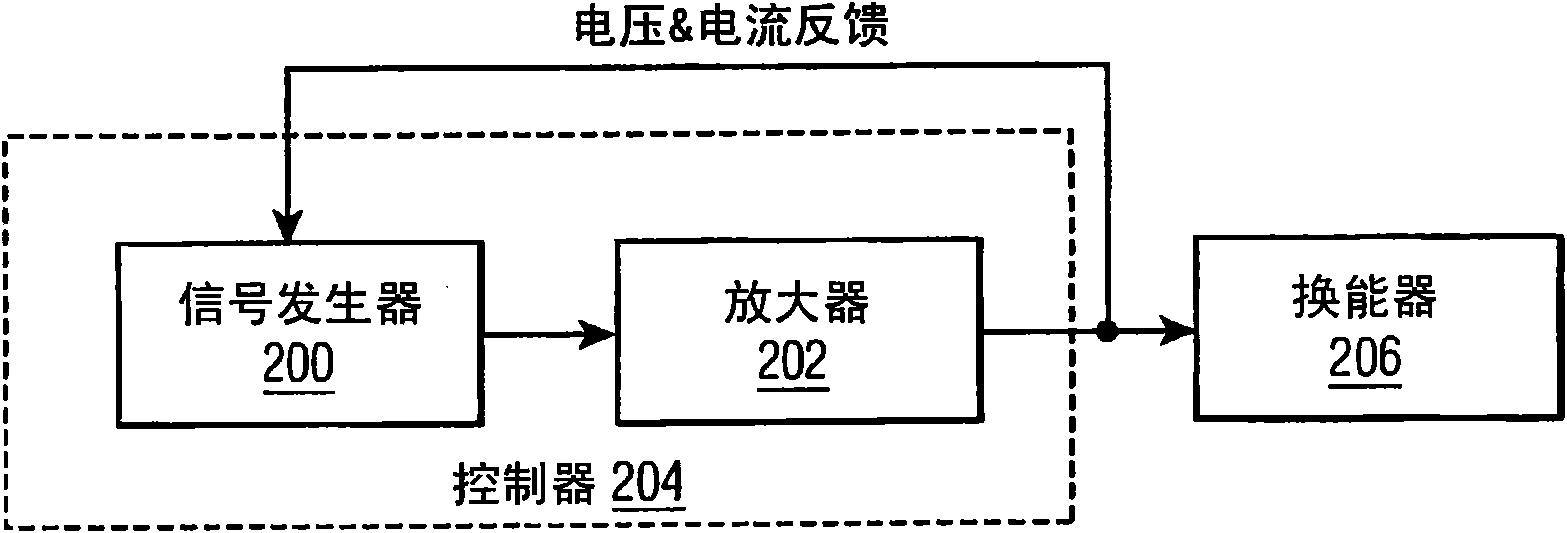

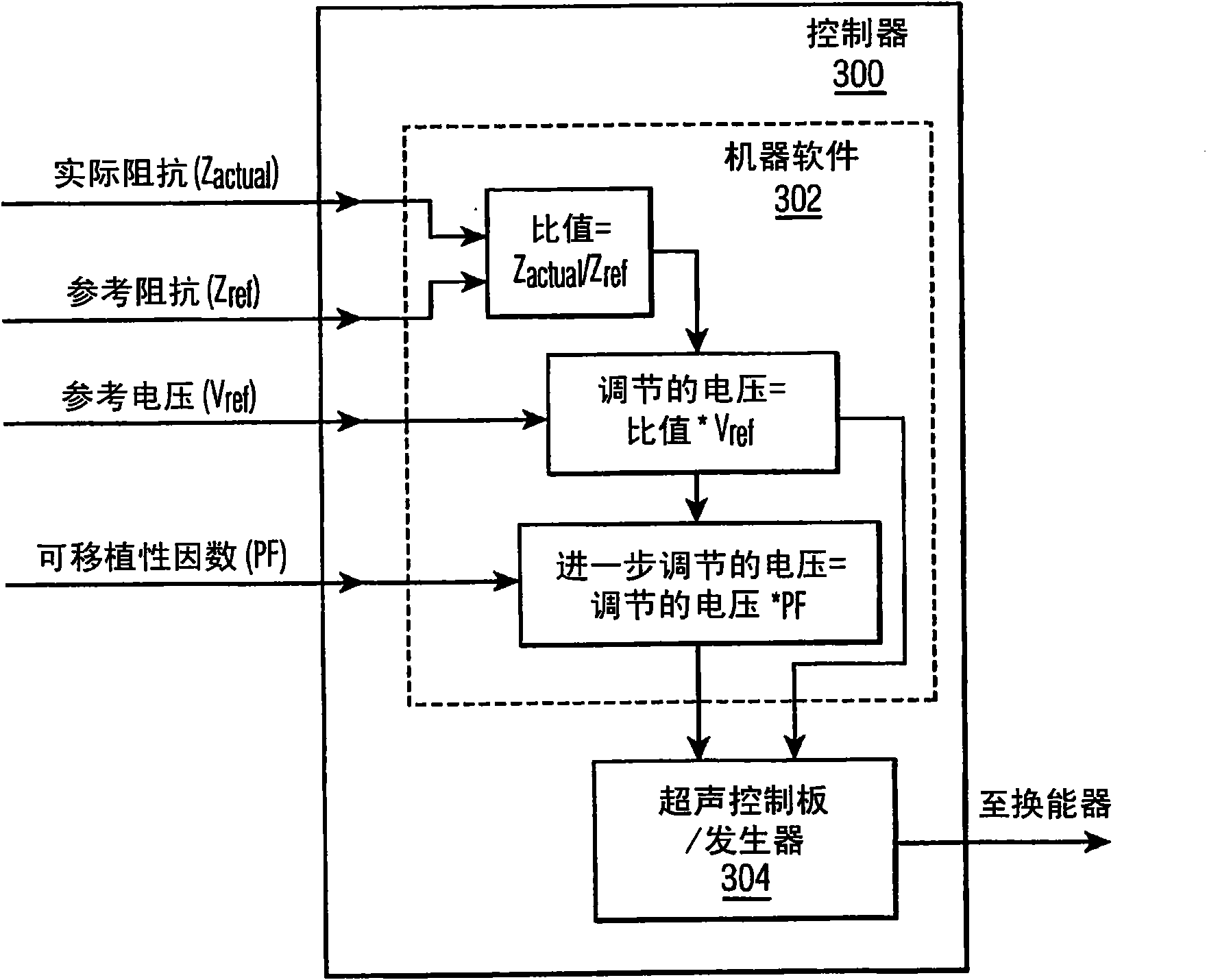

[0019] According to some exemplary embodiments of the present invention, a constant voltage control mode is used to power an ultrasonic transducer of a wire bonding system. In some applications, constant voltage is preferred, for example, because the constant voltage mode tends to be less sensitive to poor wire pin clamping and other potential problems such as wire pin resonance conditions. To overcome the portability issues of conventional constant voltage control schemes, the impedance of the ultrasound transducer (and / or the impedance associated with the operation of the ultrasound transducer) can be used to normalize the magnitude output of the voltage.

[0020] By using the improved constant voltage mode described here, several advantages can be achieved, including, for example, improved second bonding on applications with wire pins susceptible to resonance, while still maintaining machine-to-machine portability performance and compensates for changes in system impedance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com