Knitted fabric with excellent contact cool feeling and contact cool feeling intimate apparel formed by the knitted fabric

A technology for knitted fabrics and cool feeling, which is applied in knitting, weft knitting, warp knitting, etc. It can solve the problems of poor hand feeling and skin touch, unsatisfactory performance, etc., and achieve the effect of good wearing feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

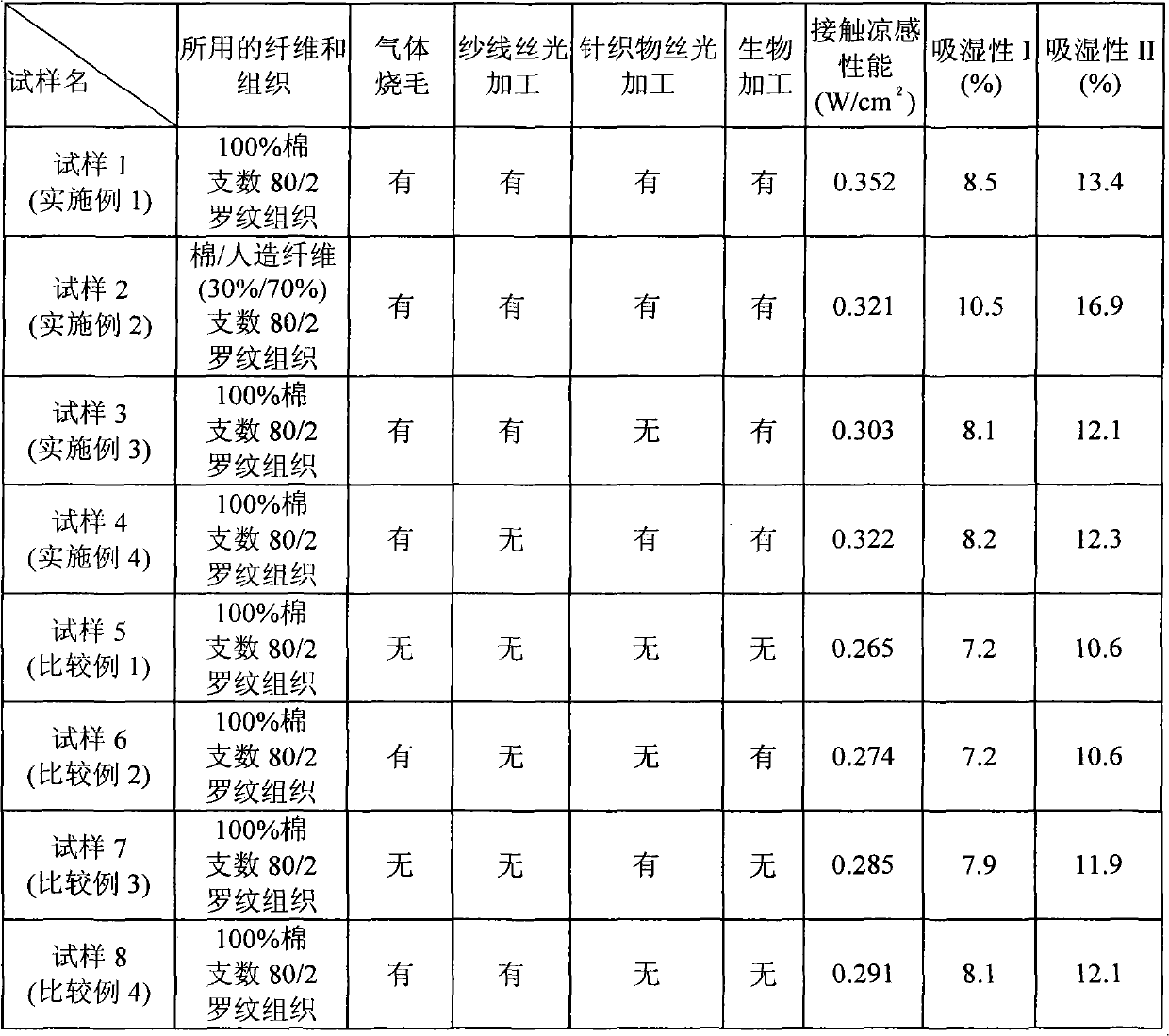

[0023] After singeing the cotton yarn with a count of 80 / 2 of 100% cotton, carry out mercerizing. Knitting the mercerized cotton yarn in a rib weave.

[0024] The knitting conditions were 30 inches, 18 needles (ゲ一ジ), and a weaving length of 456 mm / 100W. The knitted fabric is again mercerized under the same conditions and bioprocessed. In the mercerizing process, after soaking for 60 seconds in a treatment bath with a caustic soda concentration of 20%×30° C., washing with water, washing with hot water, neutralization, and washing with water are performed continuously.

[0025] In bioprocessing, after 60 minutes of treatment with a treatment bath of 2 g / l of cellulase at 50° C., washing with hot water and water, and then inactivation treatment at 80° C. for 30 minutes. The obtained knitted fabric, Sample 1, was measured for its cool-to-touch performance and hygroscopicity.

[0026] Determination of Q-max value

[0027] Place a knitted fabric cut into a 20cm square on a sampl...

Embodiment 2

[0032] Except having used the 80 / 2 yarn of cotton / rayon=30% / 70%, it processed under the same conditions as Example 1, and measured the cool-to-touch performance and hygroscopicity. The contact cooling performance of sample 2 obtained in embodiment 2 is 0.321W / cm 2 In terms of hygroscopicity, the moisture absorption under the environment of 20°C×65%RH is 10.5%, and the moisture absorption under the environment of 20°C×90%RH is 16.9%.

Embodiment 3

[0034] Knitted in a rib weave using 100% cotton thread count 80 / 2. The knitting conditions were the same as those in Example 1. Gas singeing of yarns, mercerizing of yarns, and bioprocessing of knitted fabrics are performed, but mercerizing of knitted fabrics is not performed. The contact cooling performance of the sample 3 obtained in this embodiment is 0.303W / cm 2 In terms of hygroscopicity, the moisture absorption under the environment of 20°C×65%RH is 8.1%, and the moisture absorption under the environment of 20°C×90%RH is 12.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com