Compositions comprising dye-loaded particles

A technology for cosmetic compositions and dyes, applied in medical preparations containing active ingredients, skin care preparations, pharmaceutical formulations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

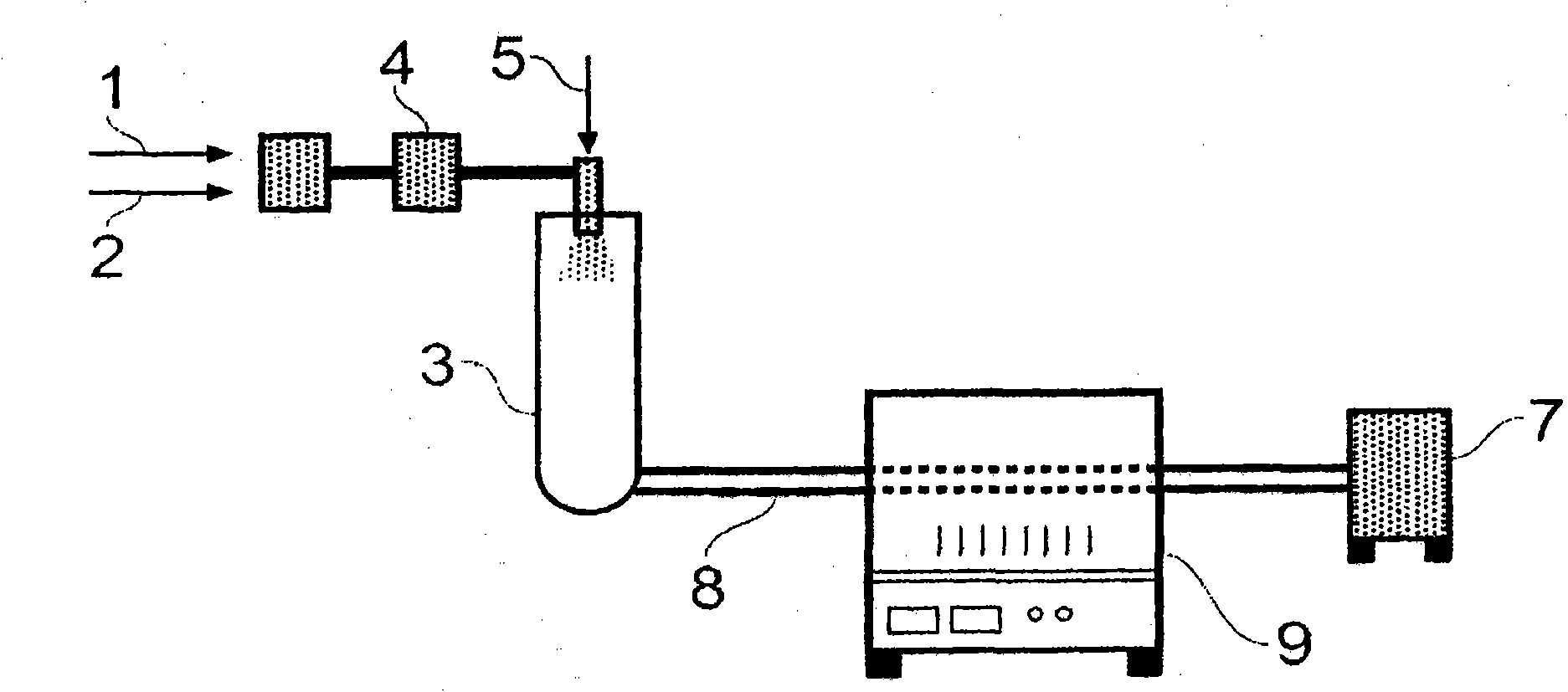

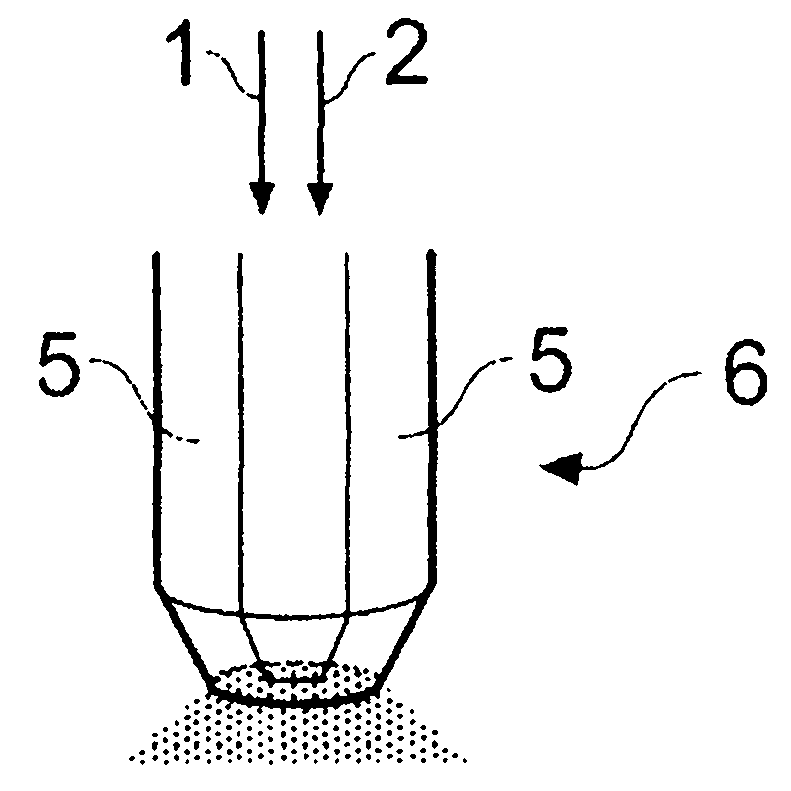

Method used

Image

Examples

Embodiment 1

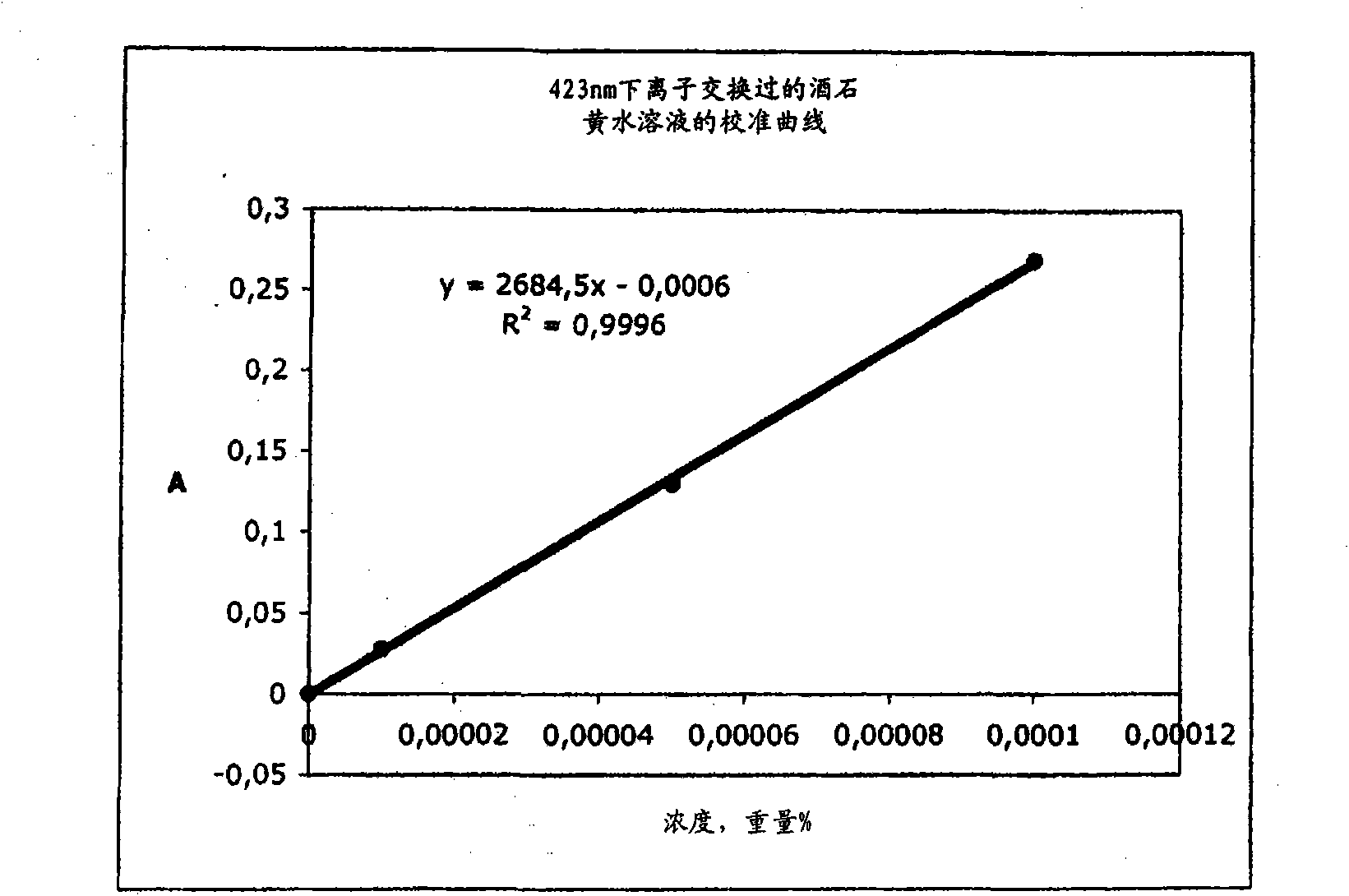

[0115] Embodiment 1: preparation absorbs the silica of tartrazine (FD&C Huang No. 5)

[0116] In the first step of the synthesis of sodium tartrate-containing silica, the dye ( Ion exchange was performed commercially available from Sigma under the trade designation T0388-100G (CAS No. 1934-21-0). This was necessary because the use of commercial tartrazine caused flocculation of the tetraethyl orthosilicate / ethanol / hydrochloric acid (TEOS / EtOH / HCl) encapsulant mixture.

[0117] Column preparation

[0118] The column was packed with 317g Dowex 50W x 8 to obtain a 400 mL bed volume.

[0119] Step 1 - Washing: To remove residual sodium cations, the column was eluted with 2.5 L of deionized water at pH 6 for 5 to 10 minutes.

[0120] Step 2 - Reconditioning: To remove bound sodium cations, wash the column with four batches of 400 mL 7% HCl, from one end to the other. The HCl contact time on the column was 45 minutes.

[0121] Step 3 - Washing: Same as Step 1.

[0122] Ste...

Embodiment 2

[0139] Embodiment 2: prepare the silica of adsorption amaranth (acid red No. 27)

[0140] This red dye is soluble in water, but it is insoluble in ethanol. However, since it does not flocculate when blended with the TEOS mixture, it is not necessary to ion-exchange the aqueous solution (as done for the tartrazine in Example 1). Also, although the dye is insoluble in ethanol, it can be used directly by increasing the proportion of water in the aerosol mixture.

[0141] sample preparation

[0142] Two separate batches of colored silica were prepared using 10.4 g TEOS, 5.4 g pH 2 HCl, and 12.0 g ethanol. The components were mixed together and the mixture was left stirring for 30 minutes. Theoretically, the mixture should provide 3 g of silica after atomization. Therefore, the amount of addition of amaranth solution (available from Sigma, catalog number A1016-100G (CAS number: 915-67-3)) was calculated based on this amount of silica. As follows: 0.3g amaranth powder and 1...

Embodiment 3

[0146] Embodiment 3: prepare the silica that adsorbs wool poppy red (FD&C blue No. 1)

[0147] This blue dye is soluble in water and ethanol, and it does not require ion exchange of the solution.

[0148] sample preparation

[0149] Two batches of colored silica were prepared using 10.4 g TEOS, 5.4 g HCl (pH 2) and 8.0 g ethanol, respectively. The components were mixed together and the mixture was left stirring for 30 minutes. Theoretically, the mixture should provide 3 g of silica after atomization. Therefore, the calculation of the addition amount of the wool poppy red solution is based on this amount of silica. It was as follows: 0.3 g of Elephanta powder (available from Sigma / Aldrich, Cat. No. 861146-25G (CAS No. 3844-45-9)) and 2.0 g of HCl (pH 2) in 3 g of ethanol. The two mixtures were mixed together and allowed to stir for 10 minutes. Subsequently, as in Example 1, the mixture was spray-dried, heated, washed, the particles were separated and the particle size ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com