Organic silicone elastomer emulsion and preparation method thereof

A silicone and emulsion technology, which is applied in the field of silicone elastomer emulsion and its preparation, can solve the problem of not getting soft and smooth skin feeling of silicone elastomer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] (4) Preparation of emulsion A:

[0097] The base polymer was prepared as follows:

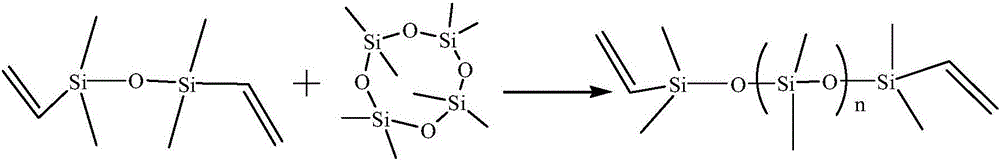

[0098]

[0099] Vinyl double headers (tetramethyldivinyldisiloxane, divinyltetramethyldisiloxane) and D 4 Under the catalysis of sulfuric acid, equilibrate at room temperature for 5 hours, let the layers stand, remove the acid solution, and use Na 2 CO 3 After neutralizing the remaining acid, filter to obtain the basic polymer-divinyl-terminated silicone oil.

[0100] n is the degree of polymerization, n=120, and the molecular weight of the base polymer is 9066;

[0101] Emulsifier: Silok-2205 (commercially available);

[0102] Catalyst: methyl vinyl siloxane coordination platinum complex;

[0103] Water phase: use pure water;

[0104] Preparation method: mix 300g of base polymer and 0.04mg of catalyst evenly and record it as I; add 40g of emulsifier into 1000mL water and mix uniformly and record it as II; add I to II at a stirring speed of 500r / min, and homogenize to obtain Em...

Embodiment 2

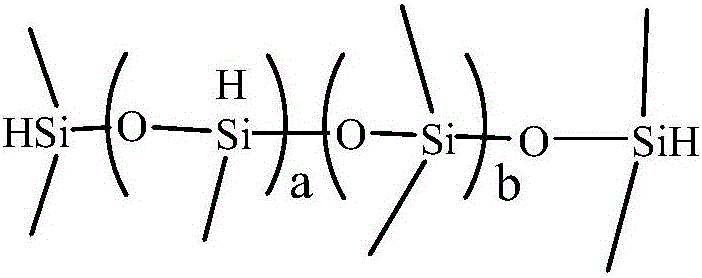

[0116] (4) Preparation of emulsion A:

[0117] Base polymer preparation:

[0118]

[0119] Vinyl double-header (tetramethyldivinyldisiloxane, divinyltetramethyldisiloxane), D 4 and heptamethylvinyl D 4 Under the catalysis of sulfuric acid, equilibrate at room temperature for 5 hours, let the layers stand, remove the acid solution, and use Na 2 CO 3 After neutralizing the remaining acid, filter to obtain the basic polymer-divinyl-terminated silicone oil containing one vinyl group in the side chain.

[0120] m and n are degrees of polymerization, m=8, n=160, and the molecular weight of the base polymer is 12714;

[0121] Emulsifier: Silok-2205 (commercially available);

[0122] Catalyst: methyl vinyl siloxane coordination platinum complex;

[0123] Water phase: use pure water;

[0124] Preparation method: mix 250g of base polymer and 0.08mg of catalyst evenly and record it as I; add 45g of emulsifier into 1000ml of water and mix evenly and record it as II; add I to II ...

Embodiment 3

[0135] (4) Preparation of emulsion A:

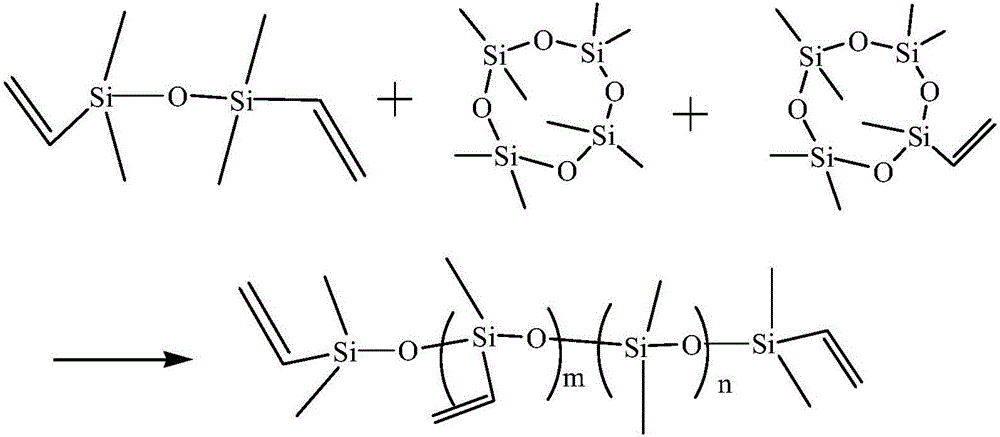

[0136] Base polymer preparation:

[0137]

[0138] Vinyl double-header (tetramethyldivinyldisiloxane, divinyltetramethyldisiloxane), heptamethylphenyl D 4 and D 4Under the catalysis of sulfuric acid, equilibrate at room temperature for 5 hours, let the layers stand, remove the acid solution, and use Na 2 CO 3 After neutralizing the remaining acid, filter to obtain the basic polymer-divinyl-terminated silicone oil containing phenyl in the side chain.

[0139] m, n is the degree of polymerization, m=10, n=120, the molecular weight of the base polymer is 10411;

[0140] Emulsifier: Silok-2205 (commercially available);

[0141] Catalyst: methyl vinyl siloxane coordination platinum complex;

[0142] Water phase: use pure water;

[0143] Preparation method: mix 300g of base polymer and 0.07mg of catalyst evenly and record it as I; add 40g of emulsifier into 1000ml of water and mix uniformly and record it as II; add I to II at a stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com