Environment-friendly polypropylene filament yarn oil agent and production method thereof

A technology of filament oil agent and production method, which is applied in the direction of fiber type, textile and papermaking, fiber treatment, etc., can solve the problem of increasing the environmental protection pressure of chemical fiber factory processing production wastewater, poor biodegradability or removability of oil agent, affecting fine denier POY fiber quality and other issues, to achieve the effect of improving dustproof and anti-wrinkle function, improving hand feel, and uniform and stable oil quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051]44Kg of fatty alcohol ether phosphate potassium salt (MOA3PK), 2.5Kg of polysiloxane polyether copolymer, 6Kg of pentaerythritol oleate, 5Kg of fatty alcohol polyoxyethylene ether (AEO-10), penetrant ethylene oxide- Propylene oxide block polyether 4.3Kg, polyethylene glycol fatty acid laurate (PEG400) 31Kg, tallow alcohol amide phosphate ester salt 14.5Kg and higher carbon isomerism alcohol phosphate ester potassium salt 5.3Kg, add reactor and mix and Heat up to 45°C within 30 minutes, stir and react for 25 minutes, then add emulsifier EL-40 35Kg, methyl-1-hydroxyethyl-2-stearyl imidazoline ammonium methylsulfate 2.3Kg, di Methyl silicone oil 5Kg, deionized water 25Kg and antiseptic JKBIO-5115 0.004Kg, the specific resistance of described deionized water is 5×10 5 Ohm, stirred and reacted at 50°C for 15 minutes, cooled to below 30°C, filtered and separated to obtain the product environment-friendly polypropylene filament oil.

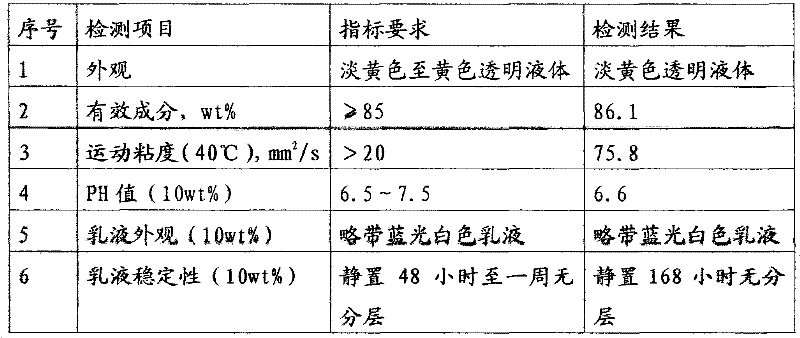

[0052] The quality index of the environmen...

Embodiment 2

[0055] Fatty alcohol ether phosphate potassium salt (MOA3PK) 51Kg, polysiloxane polyether copolymer 4Kg, pentaerythritol oleate 6.2Kg, fatty alcohol polyoxyethylene ether (AEO-10) 6.4Kg, penetrant ethylene oxide - Propylene oxide block polyether 6.2Kg, polyethylene glycol fatty acid laurate (PEG400) 36Kg, tallow alcohol amide phosphate ester salt 16.3Kg and high carbon isomer alcohol phosphate potassium salt 6.6Kg, add reaction kettle to mix And heat up to 50°C within 35 minutes, stir and react for 30 minutes, then add emulsifier EL-40 38Kg, methyl-1-hydroxyethyl-2-stearyl imidazoline ammonium methylsulfate 3.6Kg, Simethicone 6Kg, deionized water 30Kg and preservative JKBIO-5115 0.006Kg, the specific resistance of described deionized water is 5 * 10 5 Ohm, stirred and reacted at 55°C for 20 minutes, cooled to below 30°C, filtered and separated to obtain the product environment-friendly polypropylene filament oil.

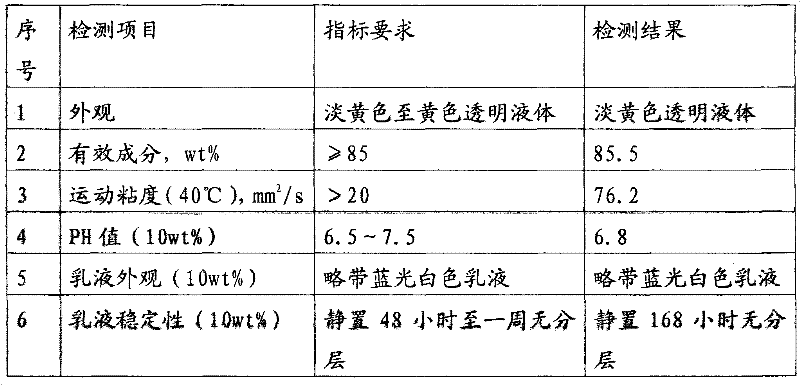

[0056] The quality index of the environment-friendly polyprop...

Embodiment 3

[0059] The fatty alcohol ether phosphate potassium salt (MOA3PK) 56Kg, polysiloxane polyether copolymer 5.5Kg, pentaerythritol oleate 7.2Kg, fatty alcohol polyoxyethylene ether (AEO-10) 8.2Kg, penetrant ethylene oxide Alkane-propylene oxide block polyether 6.4Kg, polyethylene glycol fatty acid laurate (PEG400) 41Kg, tallow alcohol amide phosphate ester salt 19Kg and higher carbon isomeric alcohol phosphate ester potassium salt 7.9Kg, add to the reactor and mix And heat up to 60°C within 50 minutes, stir and react for 40 minutes, then add emulsifier EL-40 40Kg, methyl-1-hydroxyethyl-2-stearyl imidazoline ammonium methylsulfate 4.2Kg, Simethicone 7Kg, deionized water 35Kg and preservative JKBIO-5115 0.012Kg, the specific resistance of described deionized water is 5 * 10 5 Ohm, stirred and reacted at 60°C for 20 minutes, cooled to below 30°C, filtered and separated to obtain the product environment-friendly polypropylene filament oil.

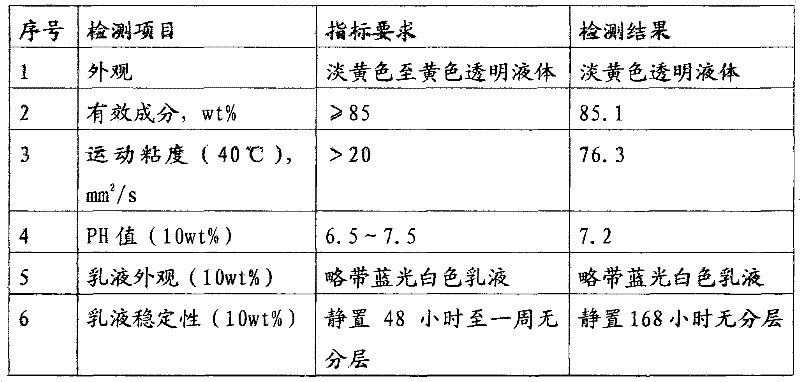

[0060] The quality index of the environmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com