Combined oscillatory flow heat pipe with evaporation and heat exchange connecting section

An oscillating flow heat pipe and evaporation heat exchange technology, applied in the field of heat transfer, can solve the problems of not being able to meet the use requirements, increase the heat dissipation area of the heat pipe, etc., and achieve the effect of improving heat transfer capacity, increasing heat transfer capacity, and prolonging heat transfer distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

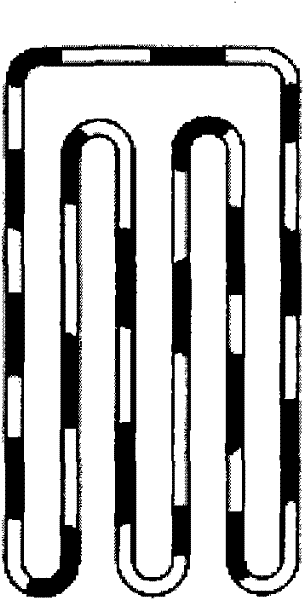

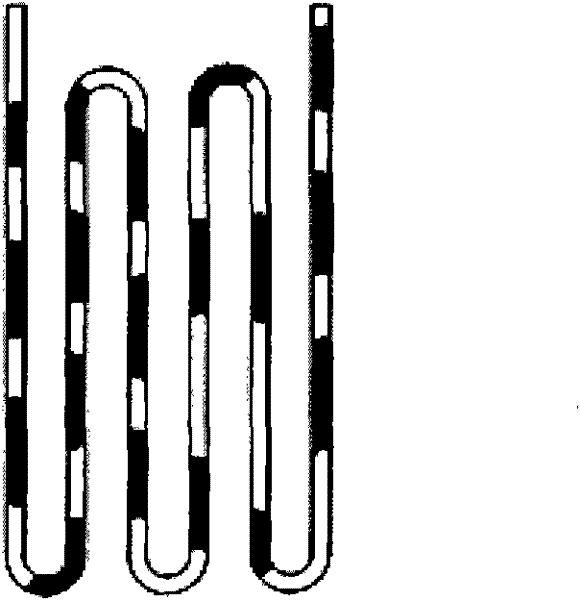

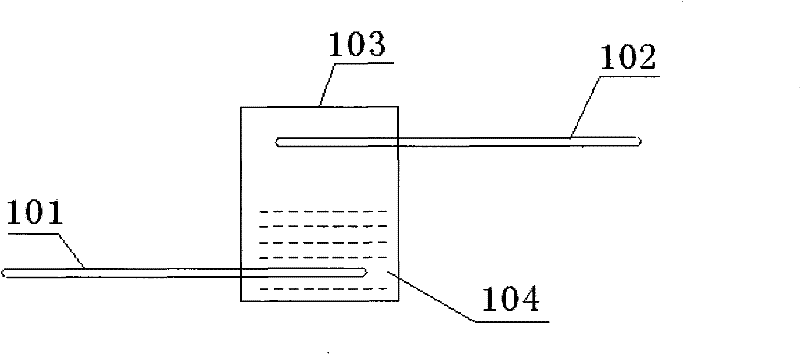

[0023] image 3 , Figure 4 , Figure 5 It is a schematic diagram of an embodiment of the present invention.

[0024] image 3 It is a schematic diagram of an oscillating flow heat pipe combination unit. like image 3 As shown, the oscillating flow heat pipe assembly unit is composed of a primary oscillating flow heat pipe 101, a secondary oscillating flow heat pipe 102, and an evaporation heat exchange connection section 103. The evaporation heat exchange connection section 103 is a vertical airtight container, and the container is filled with a working fluid 104 after vacuuming. After sealing, one end of the primary oscillating flow heat pipe 101 is placed in the evaporating heat exchange connecting section 103, and the primary oscillating flow heat pipe 101 is horizontally fixed on the lower part of the evaporating heat exchanging section 103, and one end of the secondary oscillating flow heat pipe 102 is placed in the evaporating heat exchange connecting section 103. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com