Electromagnetic induction type metal part neglected loading detection and detection method

A technology of electromagnetic induction and induction device, which is applied in the field of missing metal parts detection device, can solve the problems of product failure, need special personnel operation, accidents, etc., and achieve the effect of reducing workload, wide application value, convenient and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1 Electromagnetic Induction Type Metal Parts Missing Assembly Detector

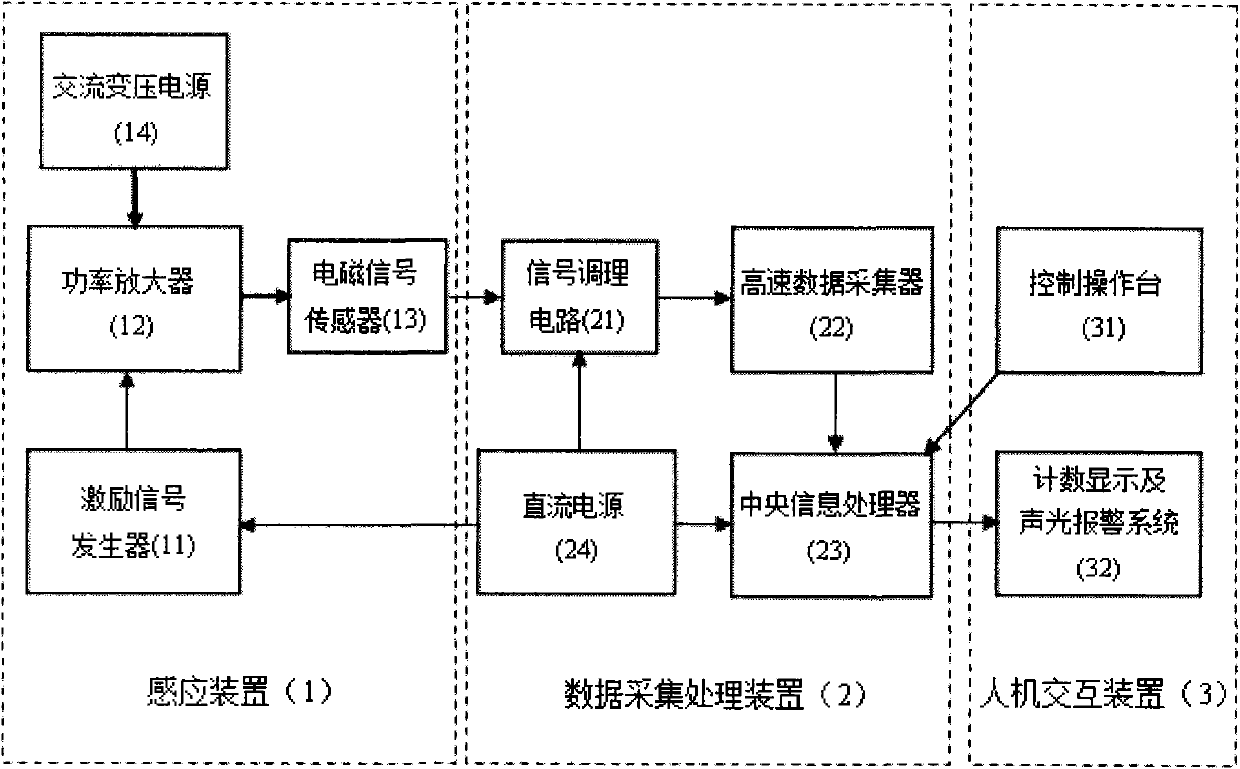

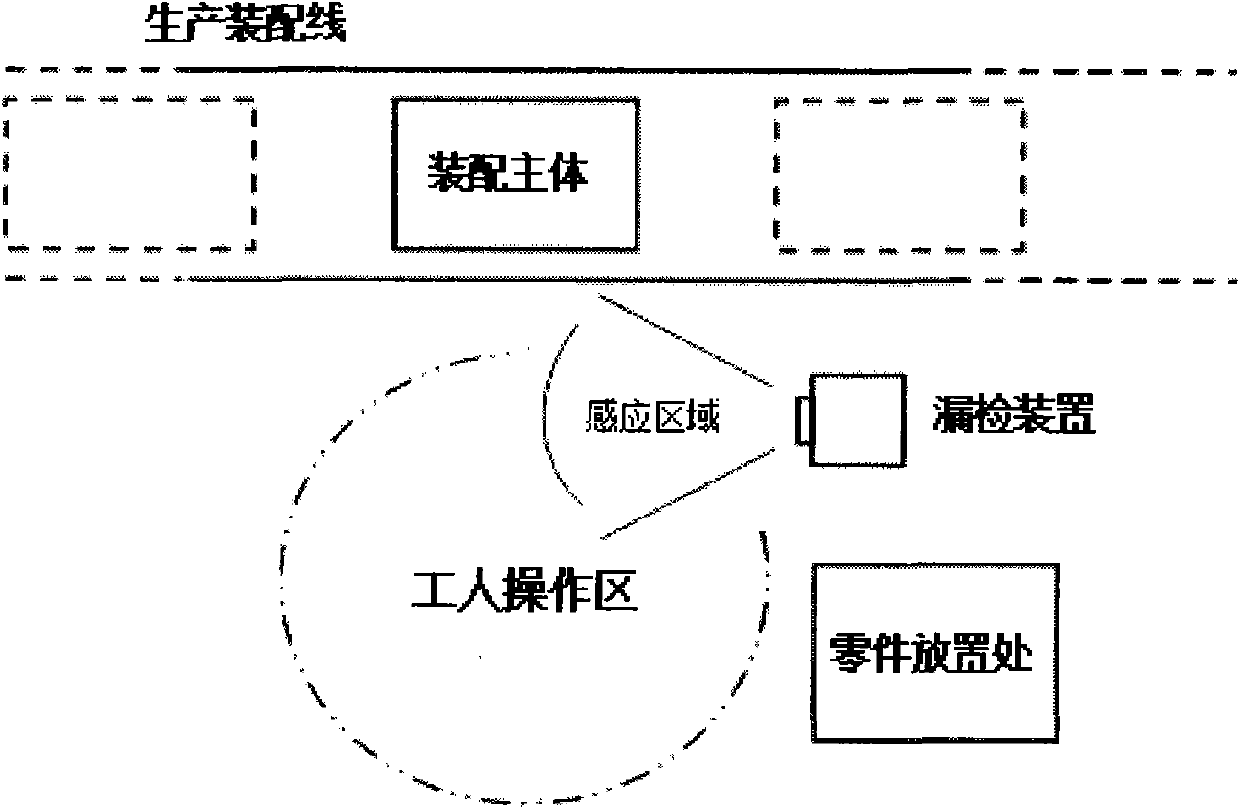

[0050] see figure 2 : Including sensing device 1, data acquisition and processing device 2 and human-computer interaction device 3, wherein

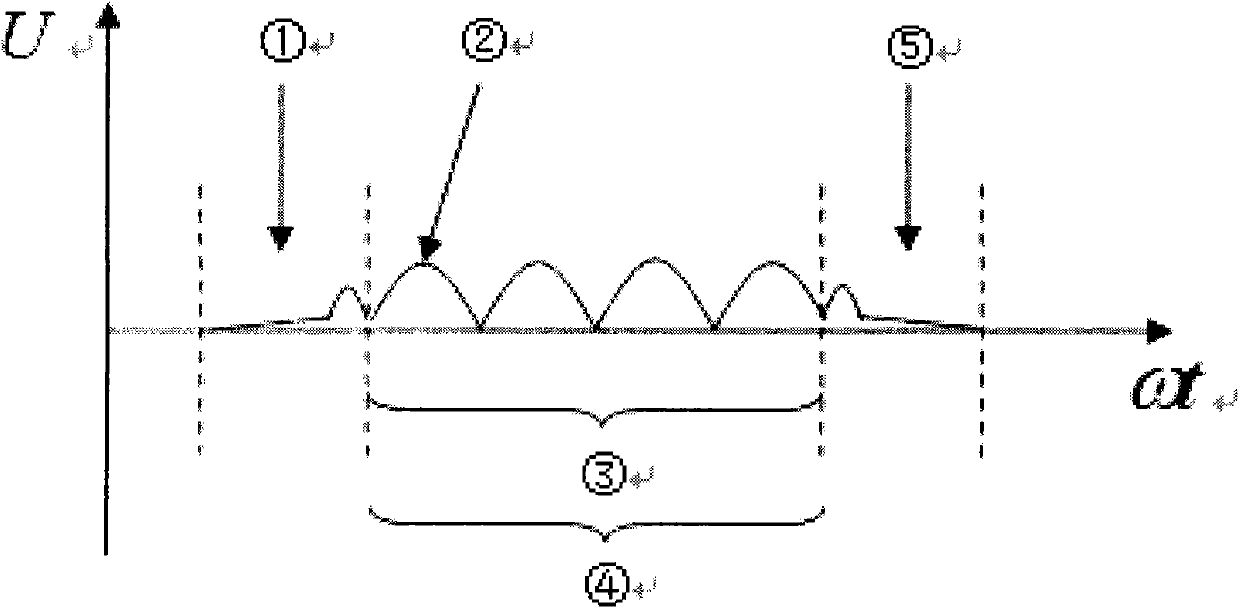

[0051]Induction device 1 comprises excitation signal generator, power amplifier 12 electromagnetic signal sensor 13, AC variable voltage power supply: excitation signal generator 11 is used for producing high-frequency sine wave voltage signal, adopts MAX038 signal generation chip of MAXIM company, its output terminal and The input terminal of the power amplifier is connected; the power amplifier 12 is used to amplify the power of the excitation signal to drive the excitation coil to generate a high-frequency alternating strong magnetic field. The high-power high-voltage DMOS high-fidelity power amplifier TDA7293 produced by ST (SGS-THOMSON) is used. , the rated output power is 100W, and its output end is connected with the input end of the excit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com