Epoxy resin composition containing isocyanurates for use in electrical laminates

A technology of resin composition and isocyanurate, which is applied in the direction of printed circuit, electrical components, etc., can solve the problem of low decomposition temperature of resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

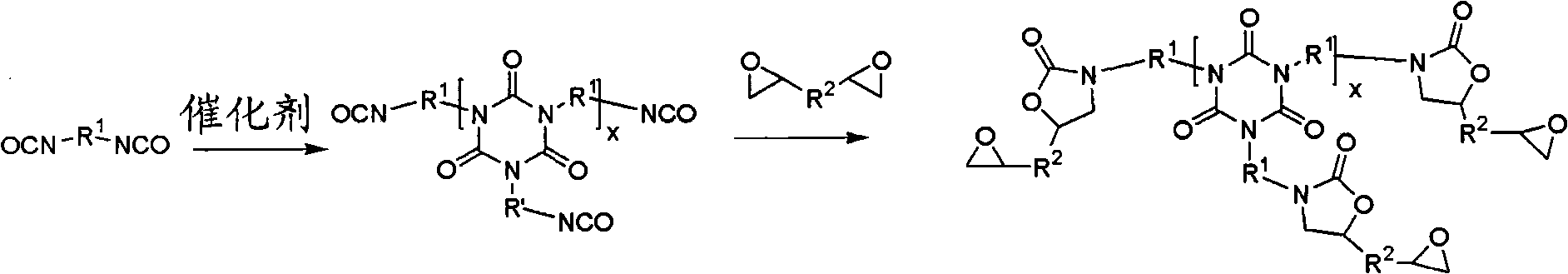

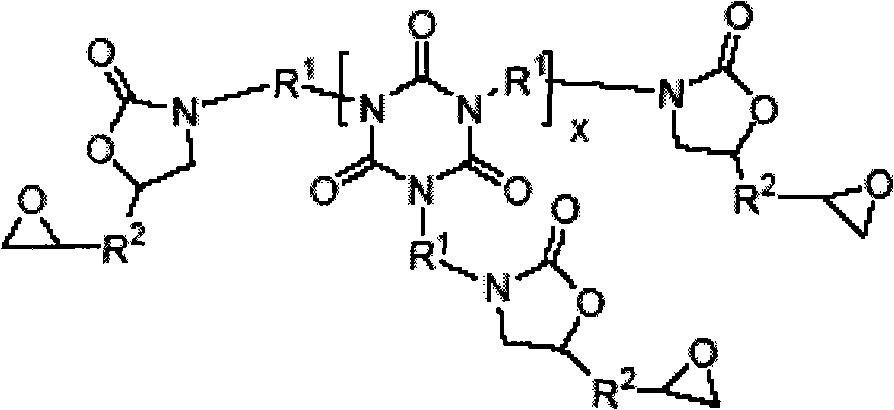

Method used

Image

Examples

Embodiment 1

[0111] will be fitted with a mechanical stirrer, addition funnel, condenser, N 2 A five-necked 1-liter glass reactor with inlet, thermometer, and heating jacket assembled into a fully vented enclosure. Ejectors of compressed air are provided so that cooling can be applied in case of excessive temperature or uncontrolled conditions. The reactor was charged with 170 g of bisphenol-A diglycidyl ether (D.E.R. TM 383, available from The Dow Chemical Co., Midland, Michigan, has an epoxy equivalent weight (EEW) of 180 g / eq, and a density of 1.20 g / cc) and 60 mg of 2-phenylimidazole (catalyst). After heating to 130°C, a 10 g portion of toluene diisocyanate (TDI, with a ratio of 2,4 / 2,6 isomers of about 80 / 20) was added to the reaction at 130-135°C for 10 minutes In the container, keep for 10 minutes. A second 10 g portion of TDI was then added over 9 minutes followed by a further 10 minutes hold. A final 10 g portion of TDI was then added over 7 minutes followed by a 5 minute wai...

Embodiment 2

[0115] The apparatus described in Example 1 was filled with 187 g of bisphenol-A diglycidyl ether (D.E.R. TM 383, available from The Dow Chemical Co., has an epoxy equivalent weight (EEW) of 180 g / eq) and 66 mg of 2-phenylimidazole. After heating to 130°C, a 10 g portion of toluene diisocyanate (TDI, with a ratio of 2,4 / 2,6 isomers of about 80 / 20) was added to the reactor at 130-135°C for 6 minutes , then hold for 7 minutes. A second 10 g portion of TDI was then added over 10 minutes followed by a further 8 minutes hold. A final 10 g portion of TDI was then added over 8 minutes followed by an 8 minute wait. The temperature was then raised to 140-145°C over 5 minutes and held for 30 minutes, then raised to 150-155°C over 5 minutes and held for 30 minutes before allowing the reactor contents to cool.

[0116] During the cooling process, the residual isocyanate level was passed through FT-IR (due to the -1 isocyanate spike) measurement. EEW of 238 g / eq, and molar ratio of o...

Embodiment 3

[0118] The apparatus described in Example 1 was filled with 170 g of bisphenol-A diglycidyl ether (D.E.R. TM 383, available from The Dow Chemical Co., has an epoxy equivalent weight (EEW) of 180 g / eq) and 60 mg of 2-phenylimidazole. After heating to 130°C, a 10 g portion of toluene diisocyanate (TDI, with a ratio of 2,4 / 2,6 isomers of about 80 / 20) was added to the reactor at 130-135°C for 10 minutes , then hold for 11 minutes. The reaction was then heated to 140-145°C and a second 10 g portion of TDI was added over 13 minutes followed by an additional 9 minute hold. A final 10 g portion of TDI was then added over 10 minutes followed by a 5 minute hold. The temperature was then raised to 150-155°C over 5 minutes and held for 30 minutes before allowing the reactor contents to cool.

[0119] During the cooling process, the residual isocyanate level was passed through FT-IR (due to the -1 isocyanate spike) measurement. EEW of 264 g / eq, and molar ratio of oxazolidinone to iso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dispersity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com