Fuel supply module

A fuel supply and fuel technology, applied in liquid fuel feeders, charging systems, machines/engines, etc., can solve problems such as difficulty in cost reduction, increase in production costs, and impact on the cost of fuel supply modules, so as to reduce production costs , Reduce production cost, simple shape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

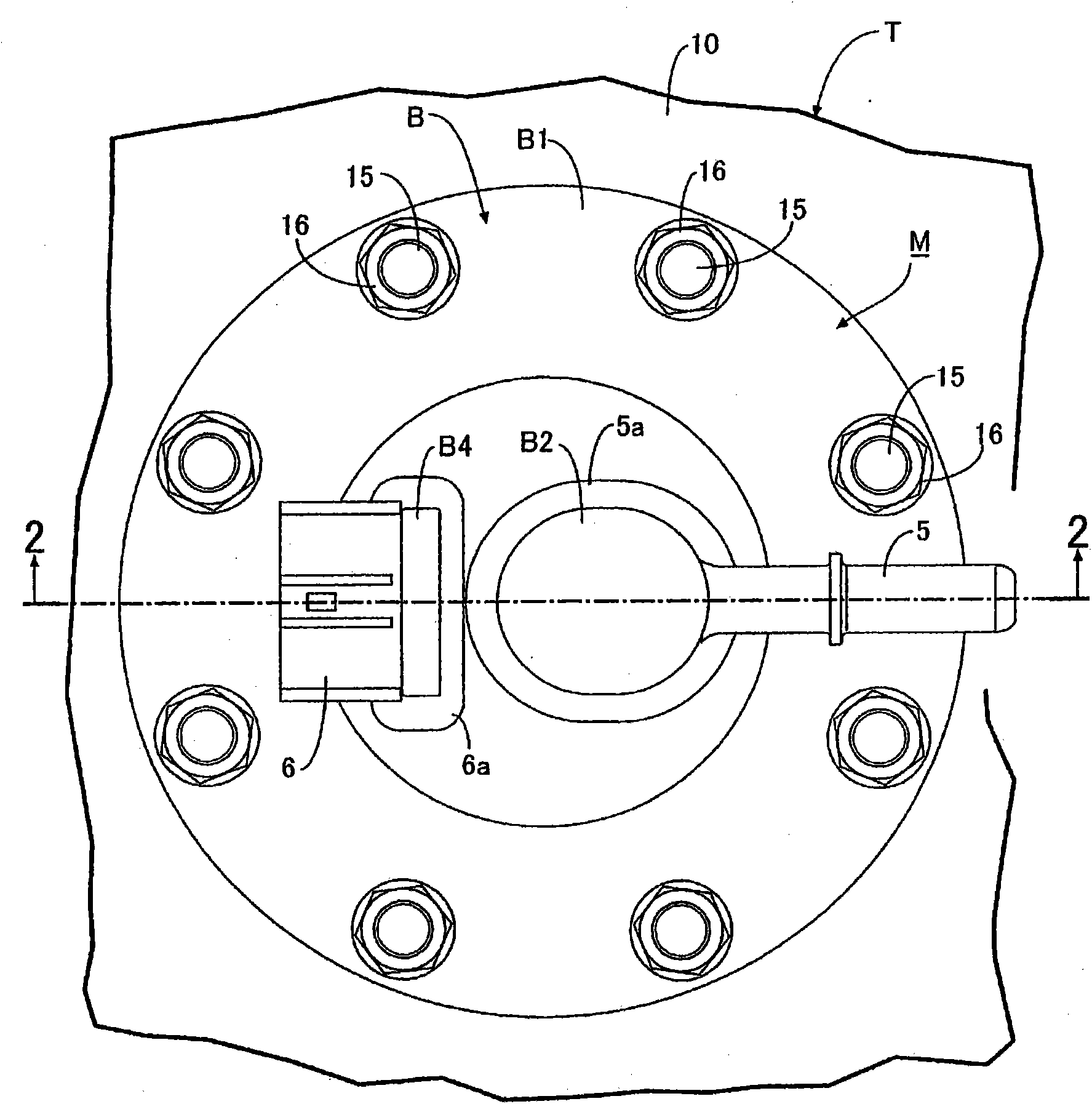

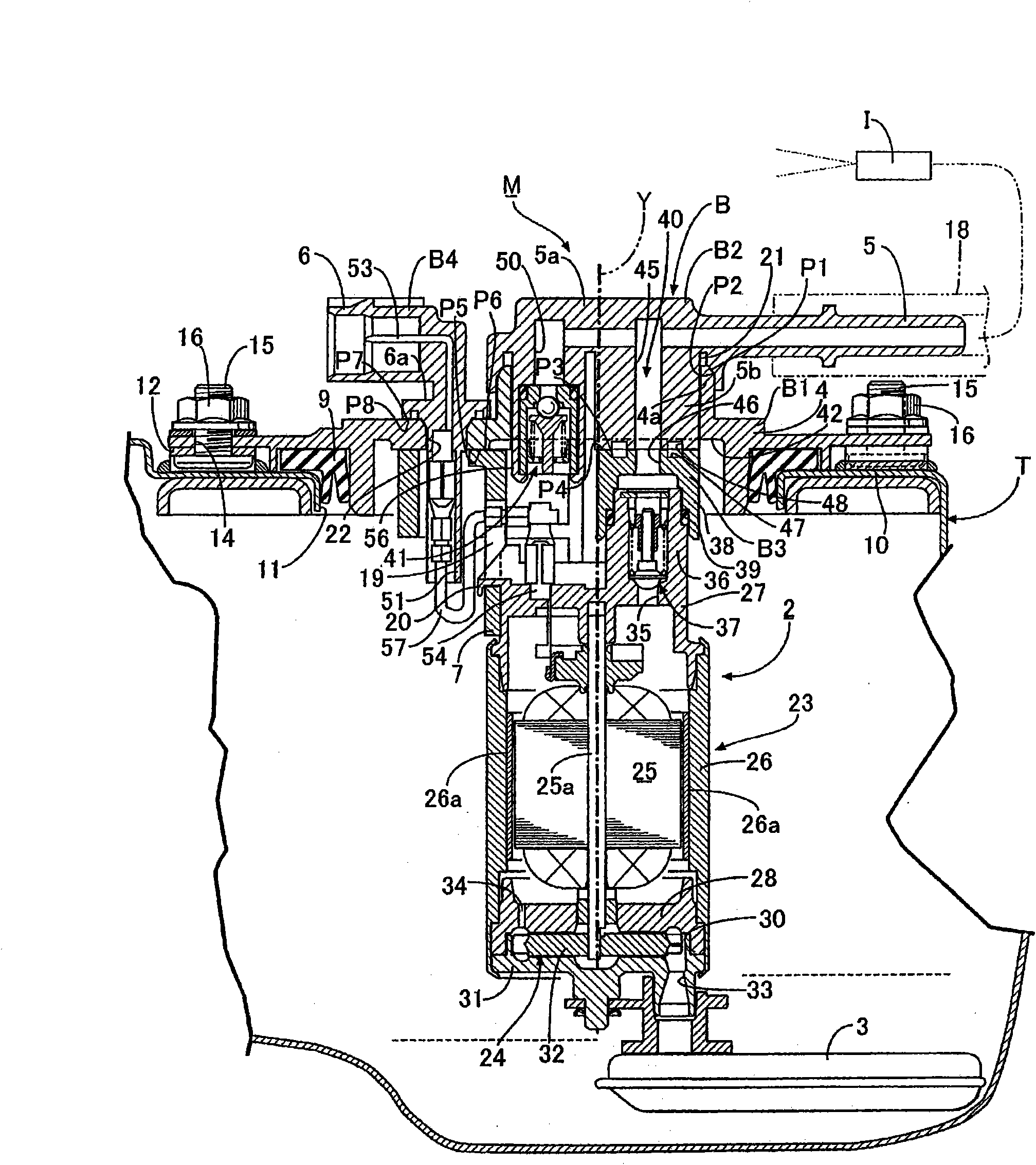

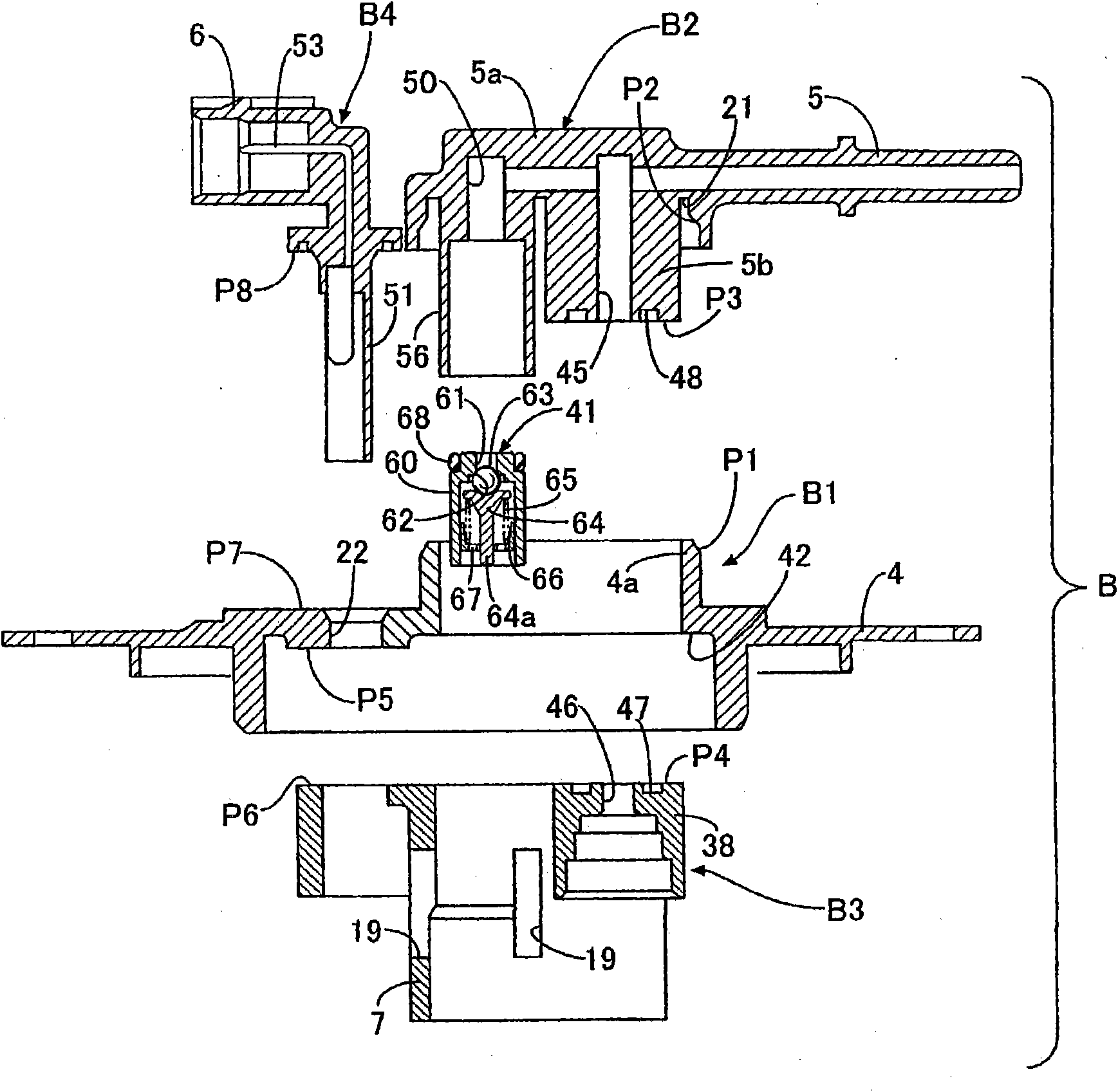

[0023] First, in figure 1 and figure 2 Among them, the fuel supply module M of the present invention that supplies the fuel in the fuel tank T to the fuel injection valve I of the engine is attached to the ceiling wall 10 of the fuel tank T mounted on a vehicle such as a motorcycle.

[0024] The fuel supply module M includes a module body B made of synthetic resin, an electric pump 2 held at the lower portion of the module body B, and a fuel filter 3 attached to the lower end of the electric pump 2 . And, the module main body B is continuously arranged on the installation base 4 by the installation base 4, the fuel delivery pipe 5 protruding from the upper surface of the installation base 4, the coupling 6 protruding from the upper surface of the installation base 4, and the installation base 4. The lower pump holding part 7 constitutes.

[0025] On the other hand, an opening 11 into which the electric pump 2 is inserted is provided inside the top wall 10 of the fuel tank T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com