Oxygen humidifying and conveying device

An oxygen humidification and oxygen delivery technology, applied in the field of medical devices, can solve the problems of reducing the probability of contamination of humidified liquid, easy breeding of bacteria, easy cross-infection, etc., so as to reduce the burden of nursing work, avoid easy breeding of bacteria, and improve antibacterial and antiseptic effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

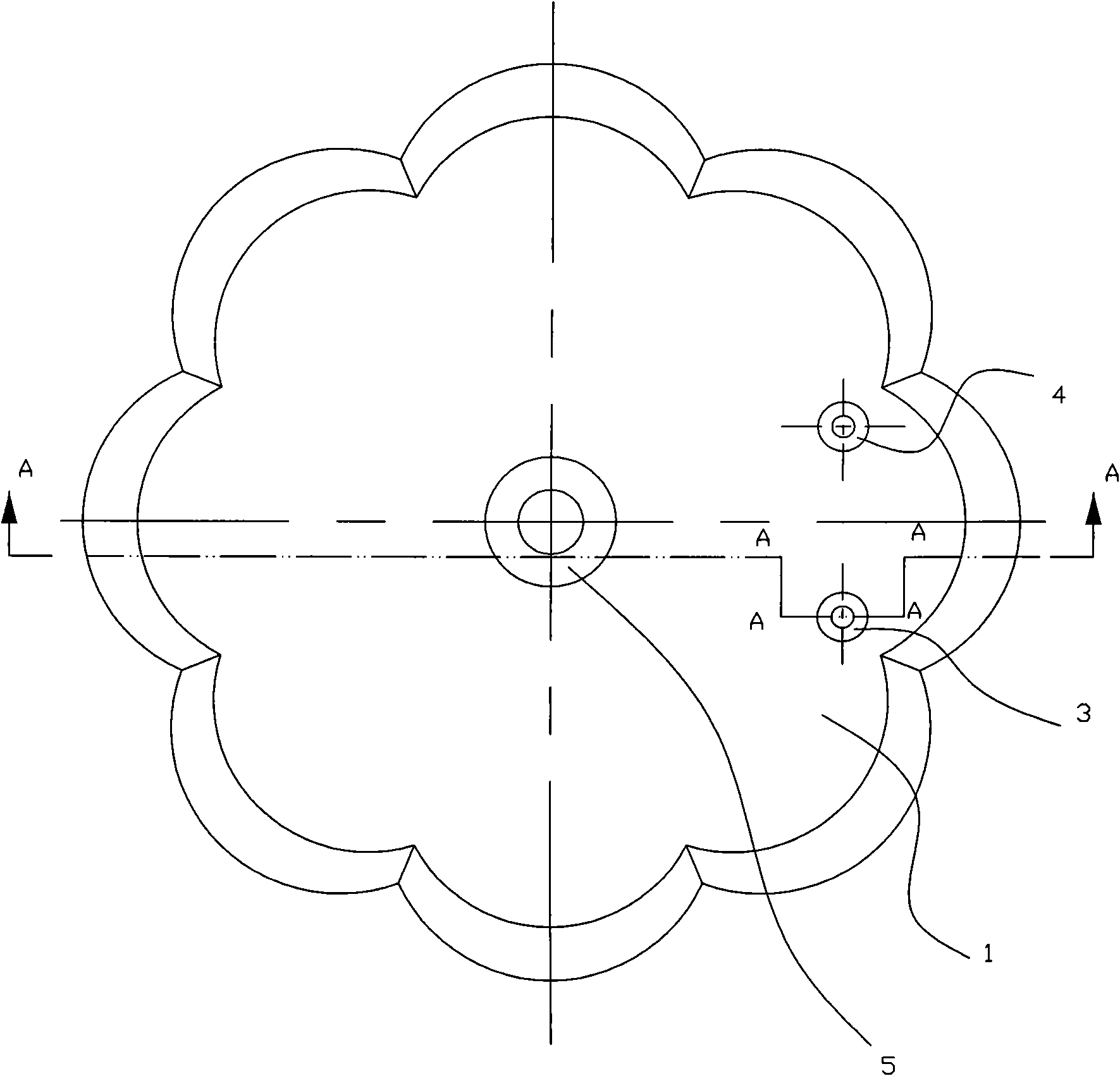

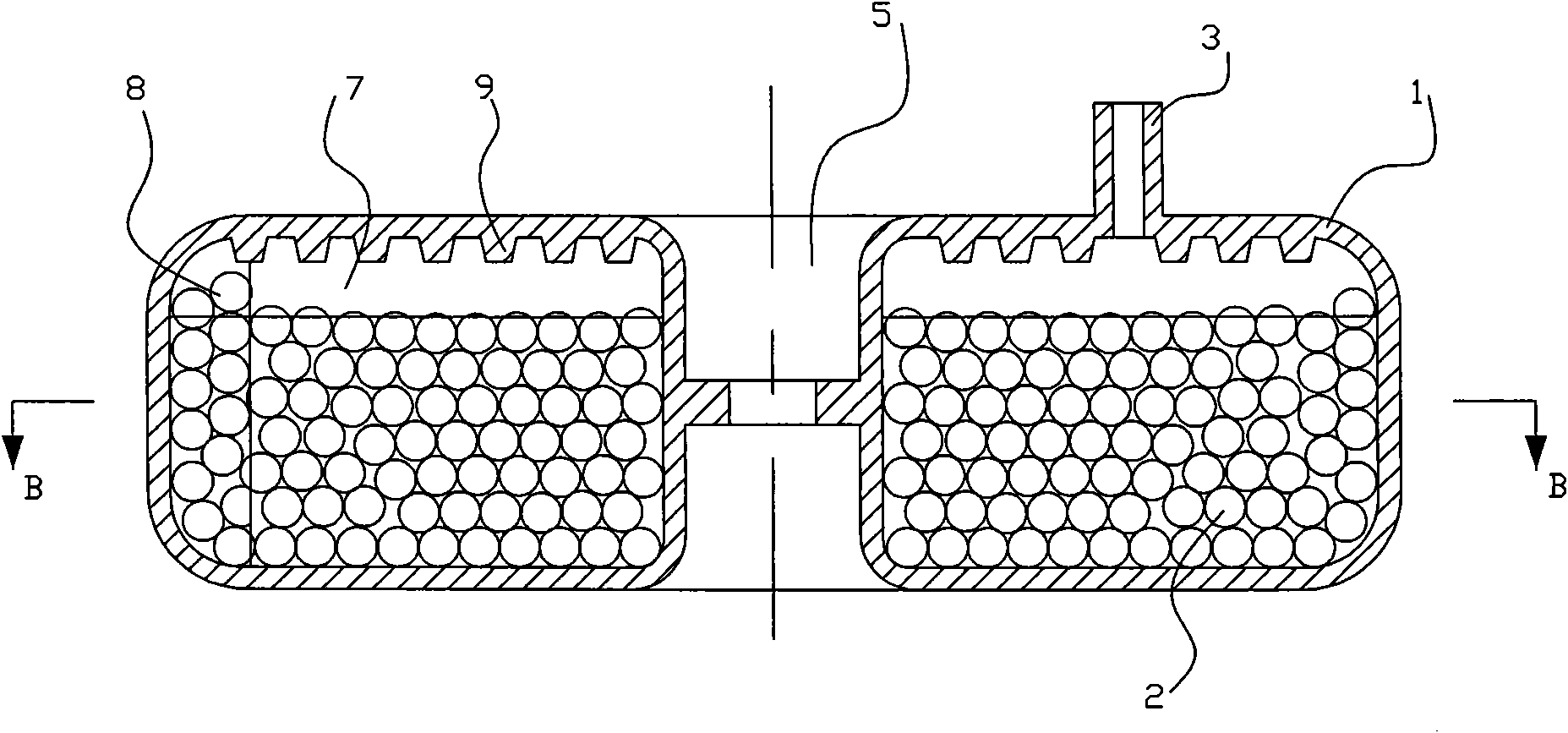

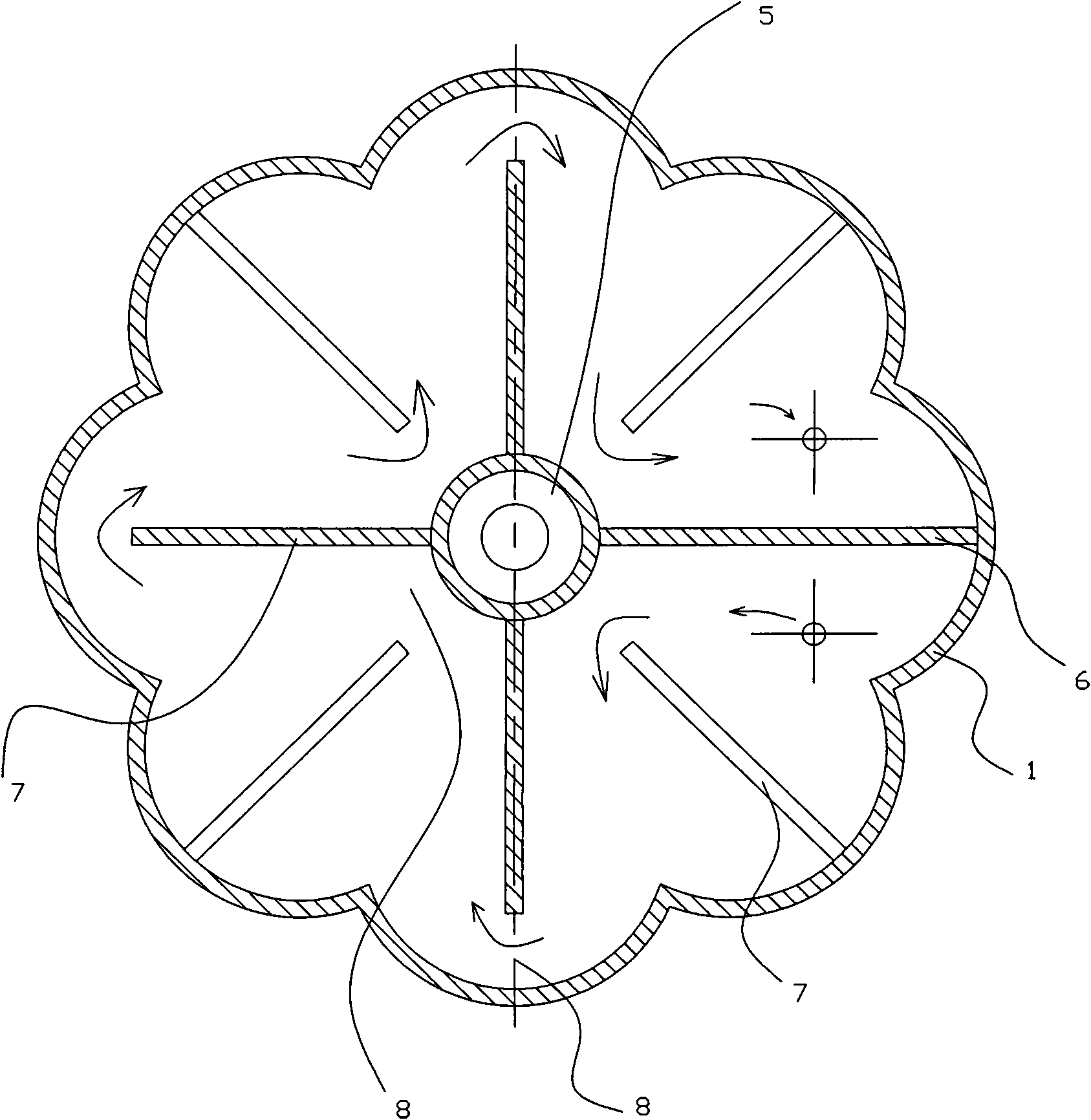

[0023] figure 1 , 2 As shown in and 3, the oxygen humidification oxygen delivery device of the present invention includes an annular closed container 1, a humidification unit 2, an oxygen input port 3, and an oxygen output port 4 of the closed container 1. The closed container 1 is formed by connecting two upper and lower shells. A central tube 5 is arranged from top to bottom in the middle of the closed container 1, and a partition 6 is arranged in the closed container 1 between the oxygen input port 3 and the oxygen output port 4. In this technical solution, the closed container In 1 there are 7 radial air baffles 7 at equal angles centered on the central tube 5, and air vents 8 are spaced between two adjacent air baffles 7 inside and outside. A plurality of evenly distributed protrusions 9 are provided on the inner surface of the upper bottom surface of the closed container 1. After the humidification unit 2 is water-absorbing and foaming of the granular super absorbent resi...

Embodiment 2

[0025] Figure 4 As shown, the humidification unit 2 is a sponge after absorbing water, and the sponge after absorbing water is put into the closed container 1 as a whole, oxygen can pass through the middle of the sponge, so as to be humidified by the water in the sponge to achieve the purpose of oxygen humidification; Polyurethane or polyether or polyvinyl alcohol can be used; at the same time, the antibacterial preservative in the humidification unit can play the role of sterilization and disinfection, and the others are the same as those described in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com