High-performance online cutting-off device

A technology for cutting devices and cutting knives, which is applied in the direction of shearing devices, devices for cutting forming blanks, and accessories for shearing machines. It can solve problems such as low productivity, low cutting frequency, and waste of surplus materials, and achieve high productivity High, high cutting precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

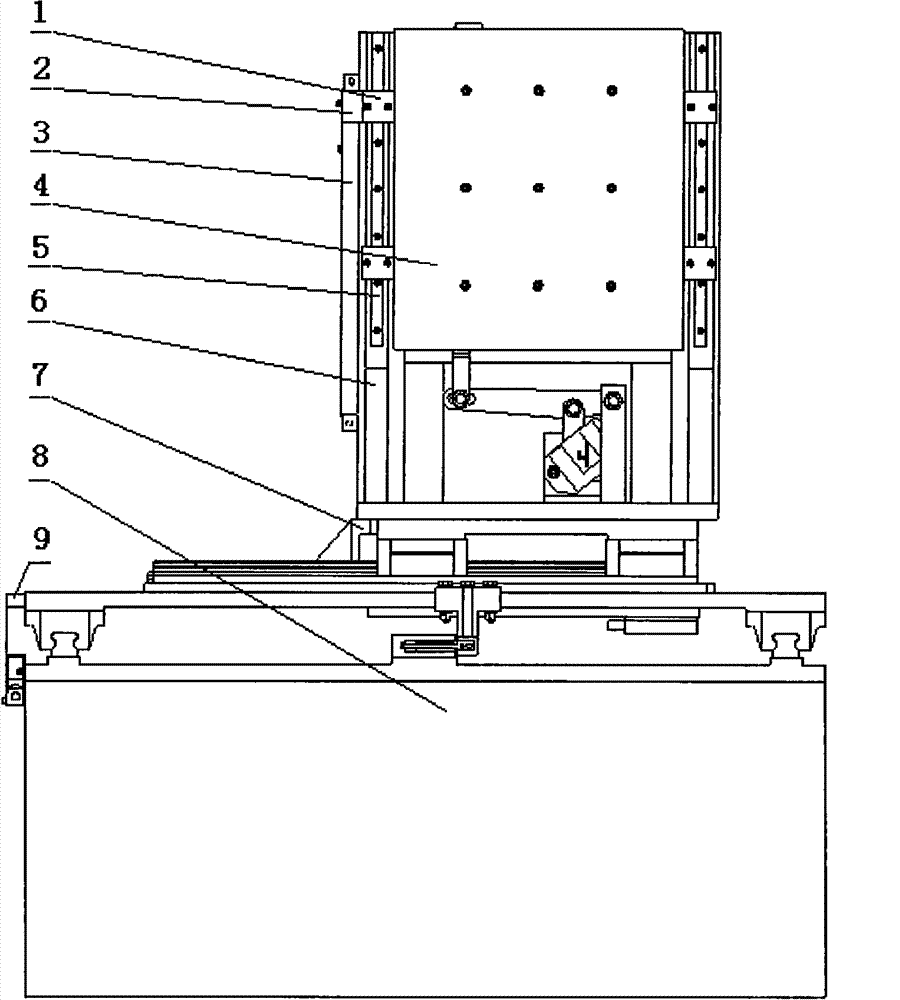

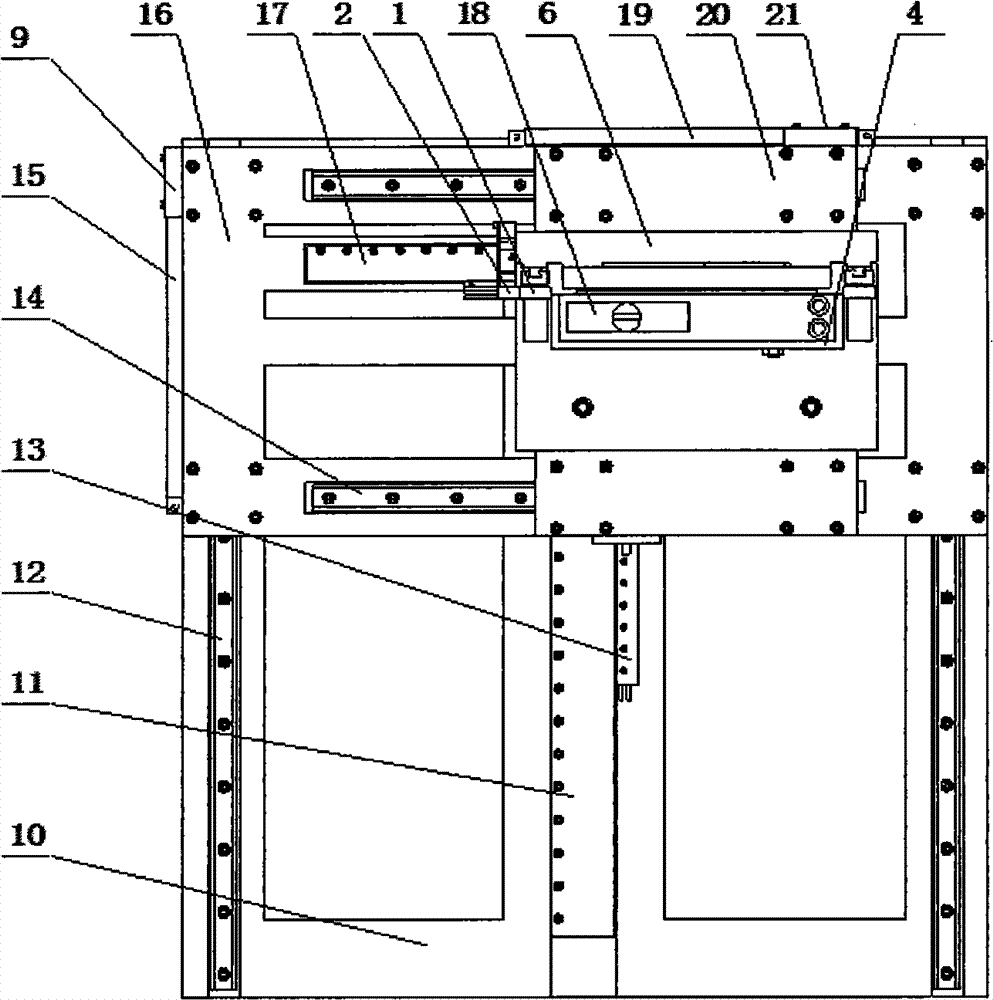

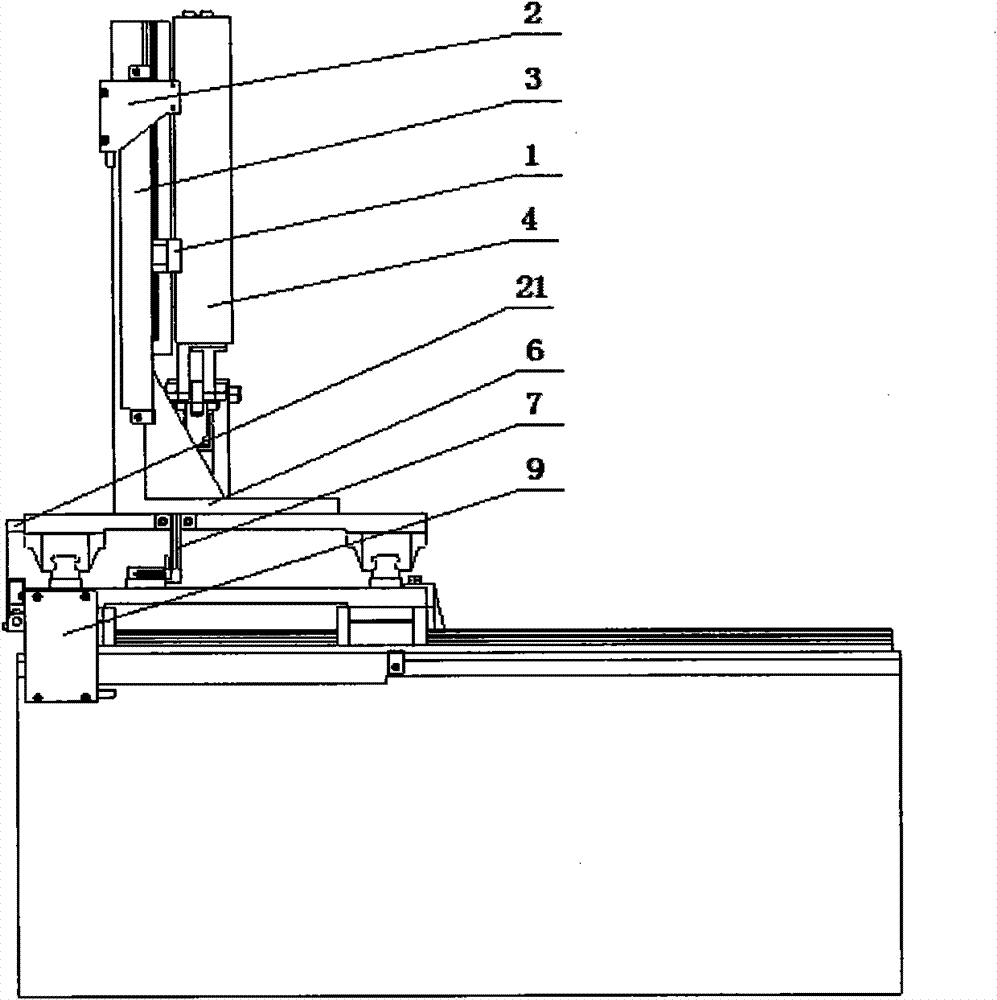

[0022] The invention discloses a high-performance online cutting device, and its preferred specific implementation is as follows Figure 1 to Figure 9 Shown:

[0023] Including a base, the base is provided with X direction (horizontal front and rear direction) guide rails and X direction linear motors, the X direction guide rail is provided with an X direction motion platform, and the X direction motion platform is provided with a Y direction (horizontal plane left and right direction) guide rail and Y direction linear motor, the Y direction motion platform is provided on the Y direction guide rail;

[0024] A cutting knife assembly is provided on the Y-direction moving platform, and the cutting knife assembly includes a cutting knife bracket, a cutting knife fixed mold, a cutting knife movable mold and a cutting knife movable mold guide sleeve, and the Y-direction moving platform is provided with a Z Direction (vertical up and down) support, the Z direction support is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com