Device for flexibly shifting cylindrical grinding machine workpiece

A technology for cylindrical grinding machines and workpieces, which is applied in the direction of grinding machines, machine tools designed for grinding the rotating surface of workpieces, manufacturing tools, etc., which can solve the problems of easily damaged center hole quality, torque asymmetry, and poor product accuracy, and achieve improvement. Grinding quality, ensuring balanced force, and improving the effect of rotation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

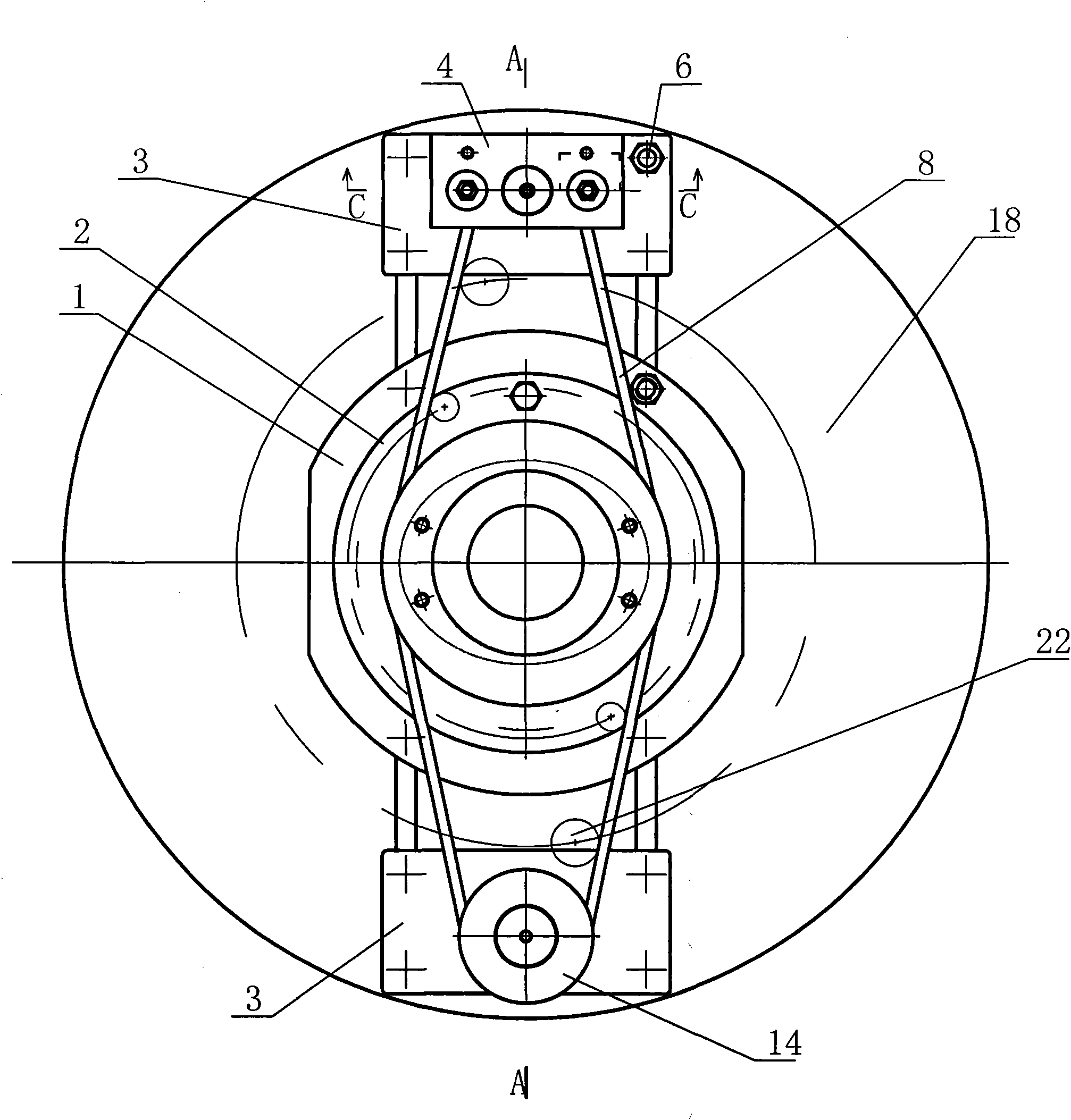

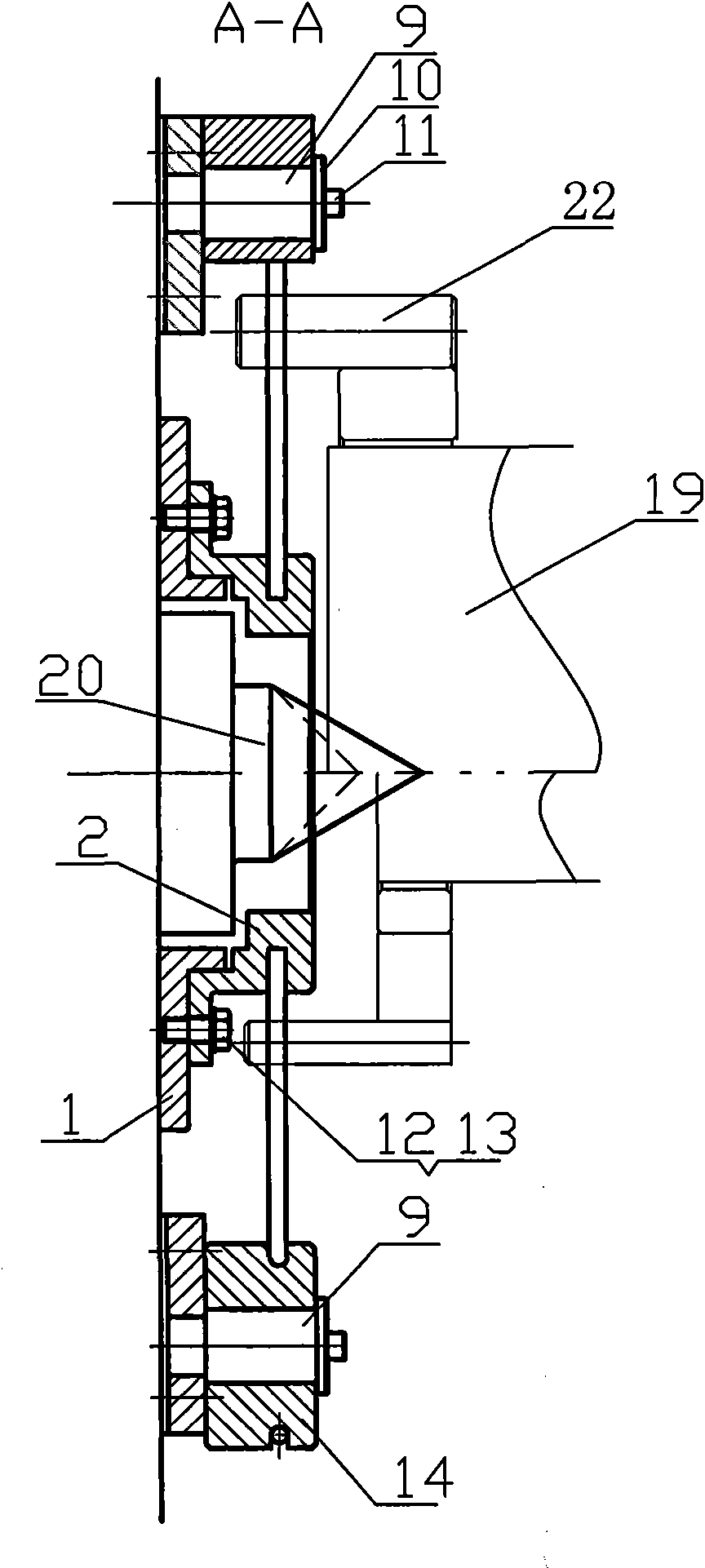

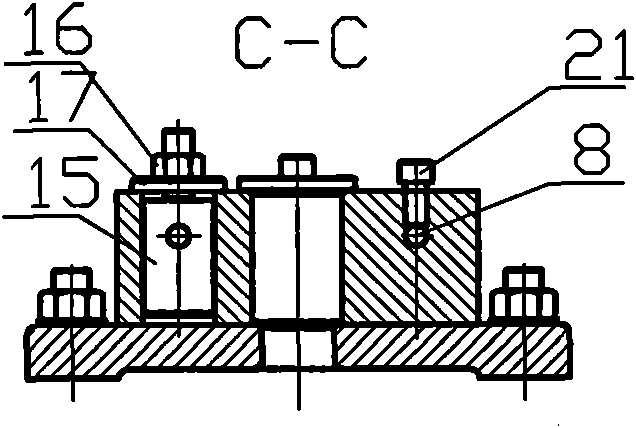

[0023] Such as figure 1 and figure 2 The workpiece soft dialing device of the cylindrical grinding machine shown is to install a turntable 2, a turnwheel 14 and a turntable 4 on the turntable 18 of the main shaft of the grinding machine. The wheel 14 and the turning block 4 are located on both sides of the turntable 2 respectively, and a steel wire rope 8 is wound between the turn block 4 , the turning wheel 14 and the turntable 2 . The turntable 2 is fixed on the grinder spindle turntable 18 through the base 1, the turn block 4 and the turn wheel 14 are respectively fixed on the two ends of the T-shaped groove of the grinder turntable 18 through a small base 3, the turn block 4 and the turn wheel 14 respectively pass through the rotating shaft 9 is assembled on the small base 3, and the gland 10 is pressed on the top of the rotating shaft 9 with the hexagon socket head cap screw 11, and the rotating block 4 and the rotating wheel 14 can rotate around the rotating shaft 9; ...

Embodiment 2

[0029] Figure 4 It is another structure of the workpiece soft dialing device for the cylindrical grinder, which is different from Embodiment 1 in that the ring groove for tensioning the steel wire rope set on the turntable 2 is a stepped ring groove. When installing the wire rope, first rotate the step-shaped ring groove so that the step line of the steps at both ends of the step-shaped ring groove is parallel to the center connection line between the turning block and the runner, then wind the wire rope in the step groove, and wrap the two ends of the wire rope After the head is fixed by the method in Example 1, rotate the turntable so that the step line of the step-shaped ring groove is perpendicular to the center connection line between the turning block and the runner, so that the wire rope ring is tensioned. The step-shaped ring groove is easy to process and convenient to manufacture, and the cost is lower than that of the elliptical ring groove.

Embodiment 3

[0031]Embodiment 1 and Embodiment 2 are generally used for large-scale cylindrical grinders to process and grind large-scale high-precision rolls and shaft parts. For small and medium-sized cylindrical grinders, the base 1 and the turntable 2 can be removed, and the T-bolt 6 can be loosened. Nut, widen the distance between the two small bases 3, after the wire rope ring is properly tensioned, the T-bolt 6 is tightened to position the two small bases 3. Because the diameter of the runner 14 and the distance between the two rotating shafts 9 are relatively large, the wire rope ring and the top 20 will not interfere during work. In this way, the structure of the soft dialing device is simplified, and the processing accuracy of the small cylindrical grinding machine can be effectively improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com