Flat-panel detector structure

A flat panel detector and detector technology, which is applied in the direction of radiation intensity measurement, etc., can solve the problems of circuit heating, the flat panel is susceptible to external shocks, etc., and achieve the effect of reducing the impact of shocks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

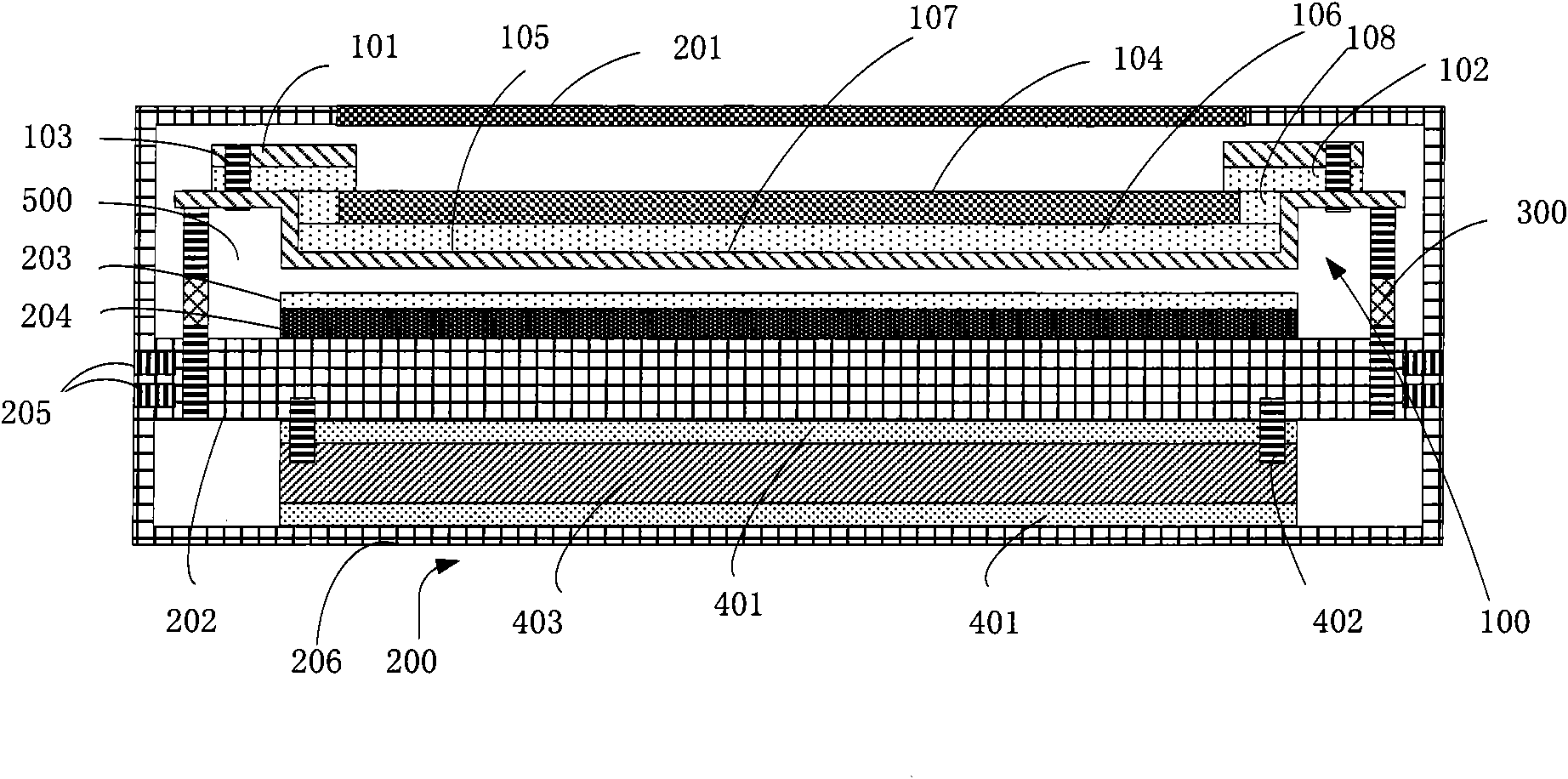

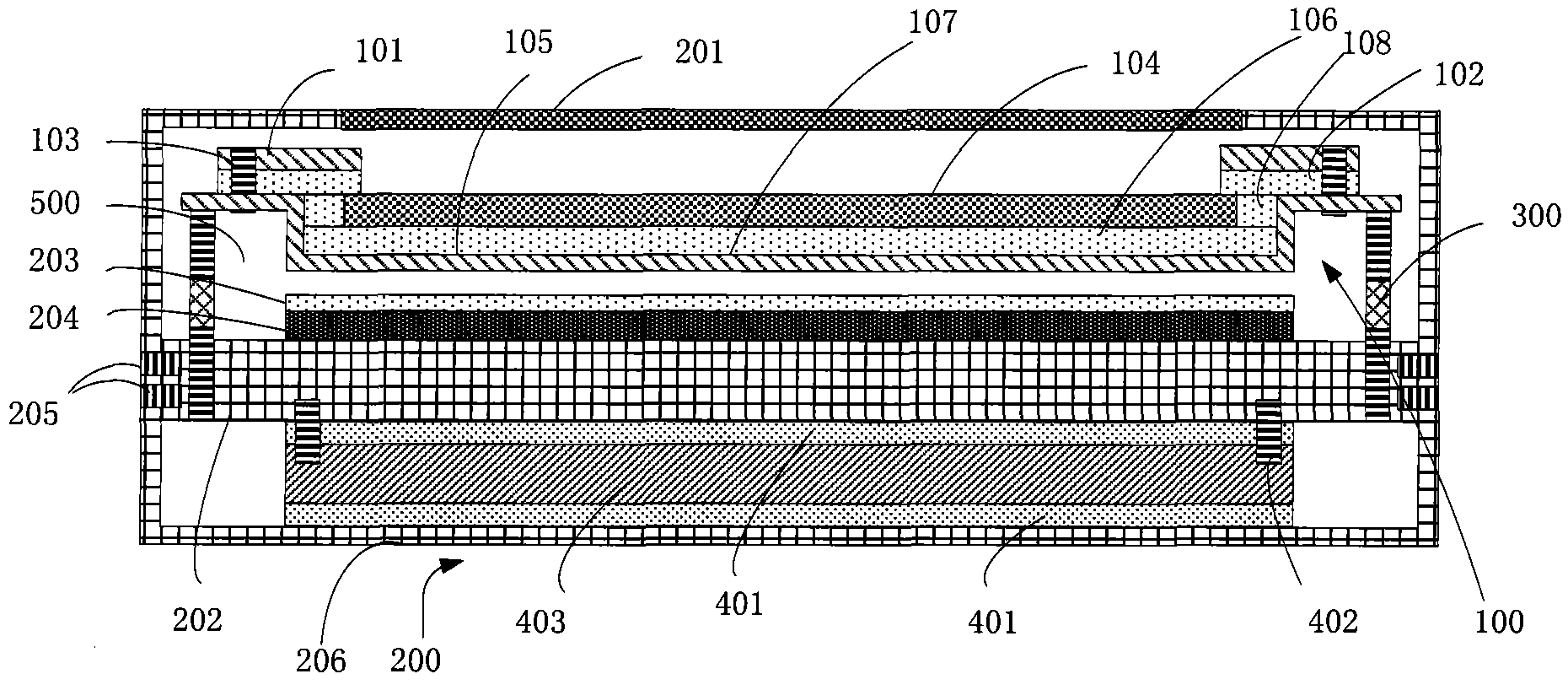

[0023] like figure 1 A modular flat panel detector structure with an inner casing is shown, which is mainly composed of an inner casing 100 , an outer casing 200 , a flat panel 104 and a PCB board 403 .

[0024] The housing 200 has an outer shell 206. The top wall of the outer shell 206 is provided with a detector window 201. The detector window 201 is located at the top of the detector and is connected with the outer shell 206. It is used to isolate the flat panel 104 from the outside space and allows almost Unobstructed access to the detector, generally carbon fiber panels are preferred. The outer shell 206 is the outer skeleton of the detector, which is used to fix and integrate all detector components. The outer casing 206 is provided with an installation frame 202 similar to a crossbeam. The installation frame 202 is an internal reinforcing rib of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com