Anti-particle dust bagging device for feed

A bagging device and anti-particle technology, which is applied in the direction of transmission, packaging, solid materials, etc., can solve the problems of waste and low efficiency, and achieve the effects of avoiding waste, improving bagging efficiency, and saving feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

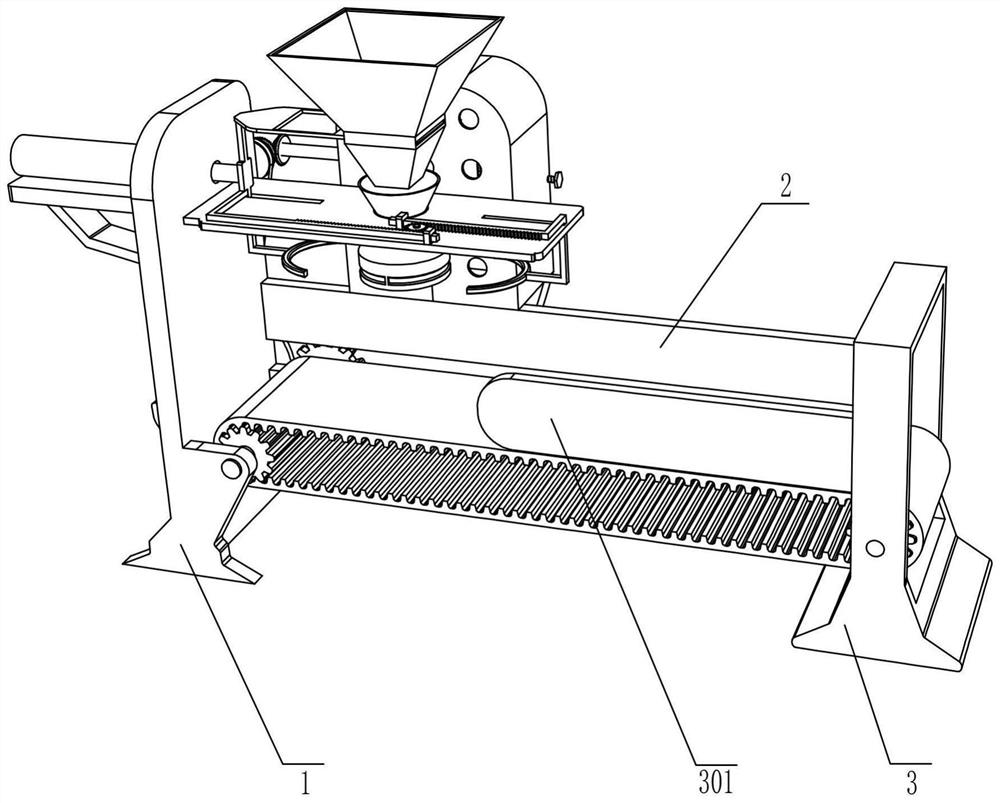

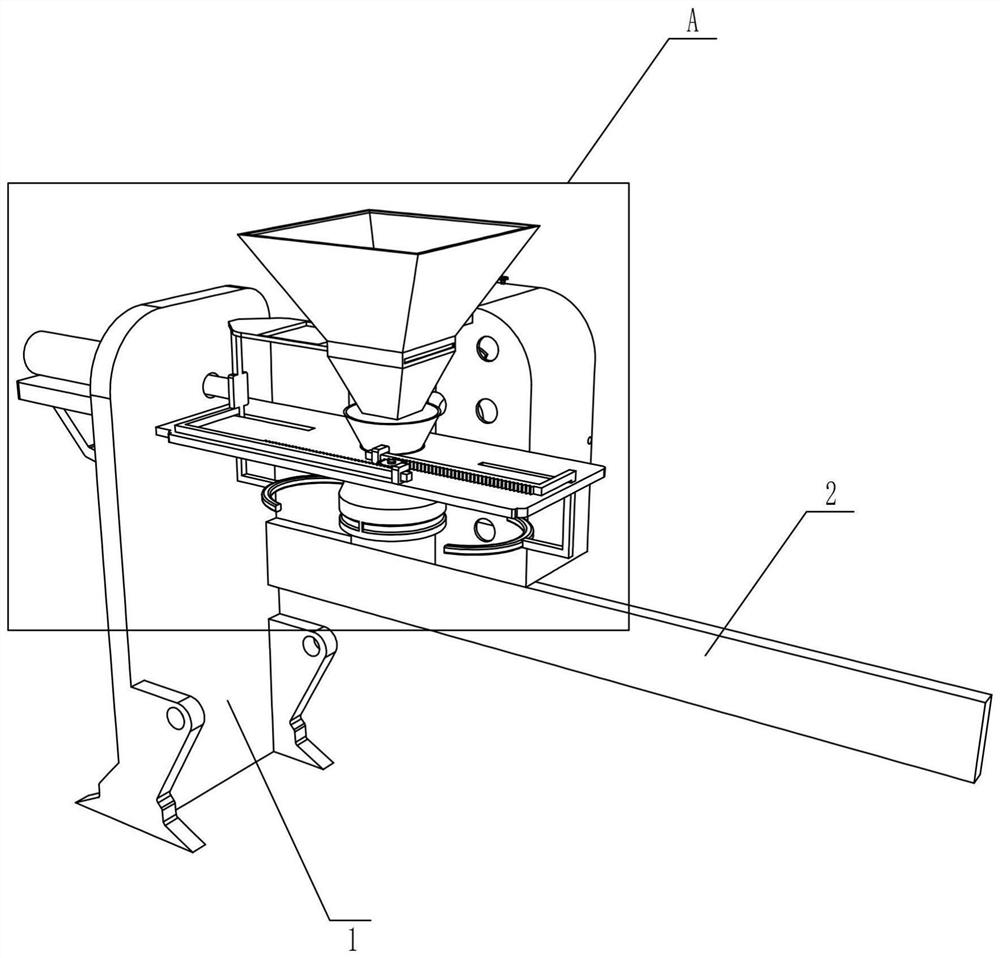

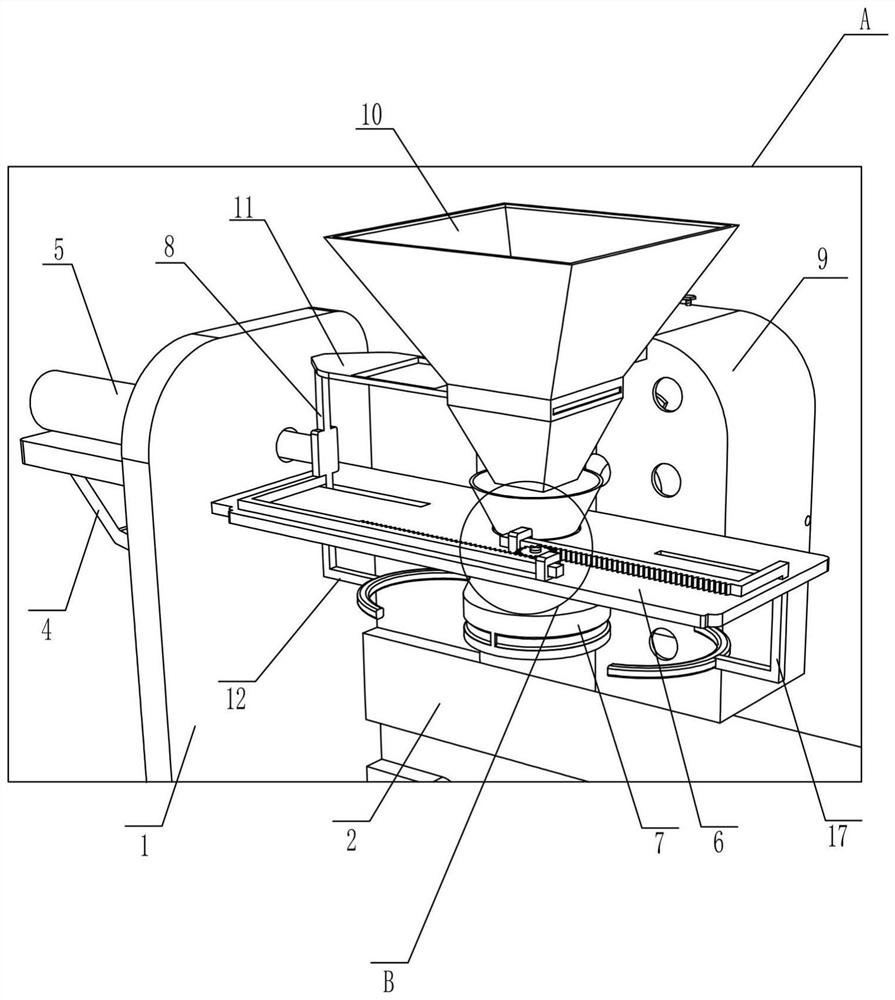

[0025] A feed anti-particle dust bagging device, such as Figure 1-9 As shown, it includes a left support seat 1, a horizontal frame 2, a right support seat 3, a guardrail 301, a mounting frame 4, an electric push rod 5, a mounting plate 6, a funnel 7, a blanking mechanism and a clamping mechanism. The functioning horizontal frame 2 is fixedly installed on the right side of the left support base 1, the supporting right support base 3 is fixedly installed on the right end of the horizontal frame 2, and the protective guardrail 301 is fixedly installed on the left side of the right supporting base 3 And it is at the same level as the horizontal frame 2, the supporting mounting frame 4 is fixedly installed on the left side of the left support seat 1, the electric push rod 5 playing a driving role is fixedly mounted on the mounting frame 4 and the right end passes through the left The support base 1, the mounting plate 6 with two slotted holes is fixedly installed on the right sid...

Embodiment 2

[0030] On the basis of Example 1, such as Figure 1-9As shown, it also includes a dust suction mechanism capable of sucking feed dust, and the dust suction mechanism includes a support rod 18, an installation housing 19, a rotating shaft two 20, a fan blade 21, a rotating shaft three 22, a bevel gear one 23, and a clamping plate 24 , filter screen 25, filter pipeline 26, bolt 27, rotating shaft four 28, pulley one 29, bevel gear two 30, supporting plate 31, motor 32, pulley two 33 and belt 34, described support bar 18 that plays a fixed role Fixedly installed on the inside of the dust collection box 9, the protective installation housing 19 is fixedly installed on the right end of the support rod 18 and is located in the dust collection box 9, the second shaft 20 is installed on the installation housing 19 through a bearing and the shaft The second 20 passes through the installation housing 19, the fan blade 21 that can generate suction is fixedly installed on the front end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com