Semi-automatic seed oyster device

A semi-automatic, sliding installation technology, applied in fish farming, application, climate change adaptation, etc., can solve problems such as limited auxiliary capacity, low production efficiency, and excessive physical exertion of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

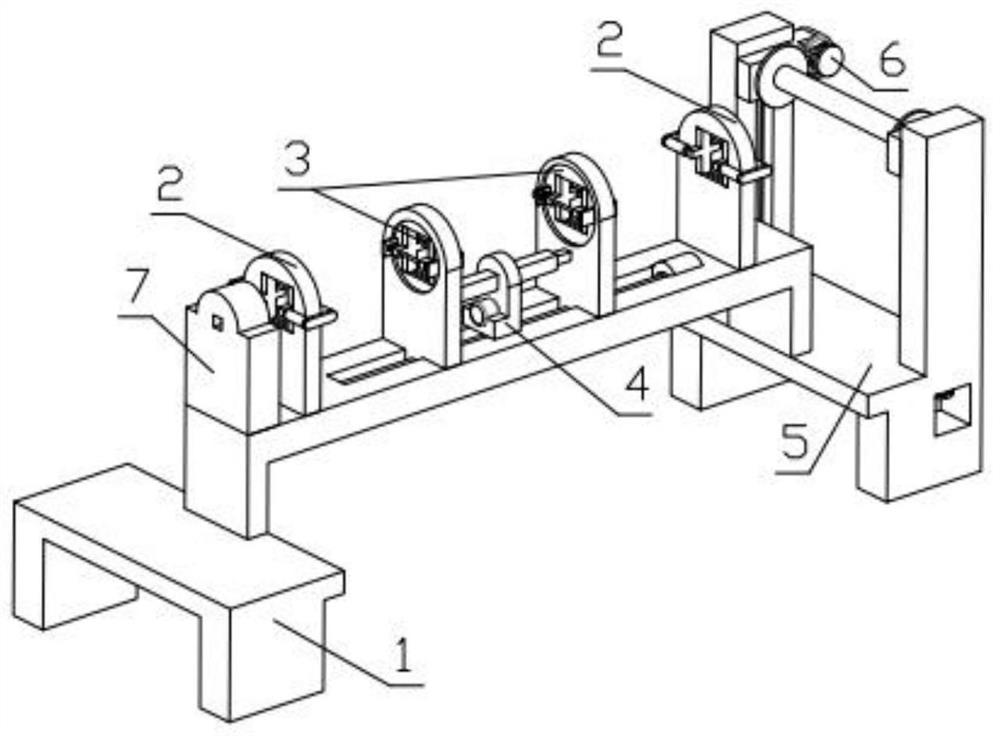

[0031] Combine below Figure 1-13Describe this embodiment, a kind of semi-automatic oyster seedling device, comprise base 1, positioning mechanism 2, broken force mechanism 3, synchronous adjustment mechanism 4, height adjustment mechanism 5, winding mechanism 6 and limit plate 7, described limit The plate 7 is fixedly installed on the base 1, the positioning mechanism 2 is fixedly installed on the base 1, the breaking force mechanism 3 is fixedly installed on the base 1, the synchronous adjustment mechanism 4 is fixedly installed on the base 1, the breaking force mechanism 3 and the synchronous adjustment mechanism 4 Engaged with each other, the height adjustment mechanism 5 is fixedly installed on the base 1, and the winding mechanism 6 is slidably installed in the groove provided on the height adjustment mechanism 5, and the height adjustment mechanism 5 is threadedly connected with the winding mechanism 6.

specific Embodiment approach 2

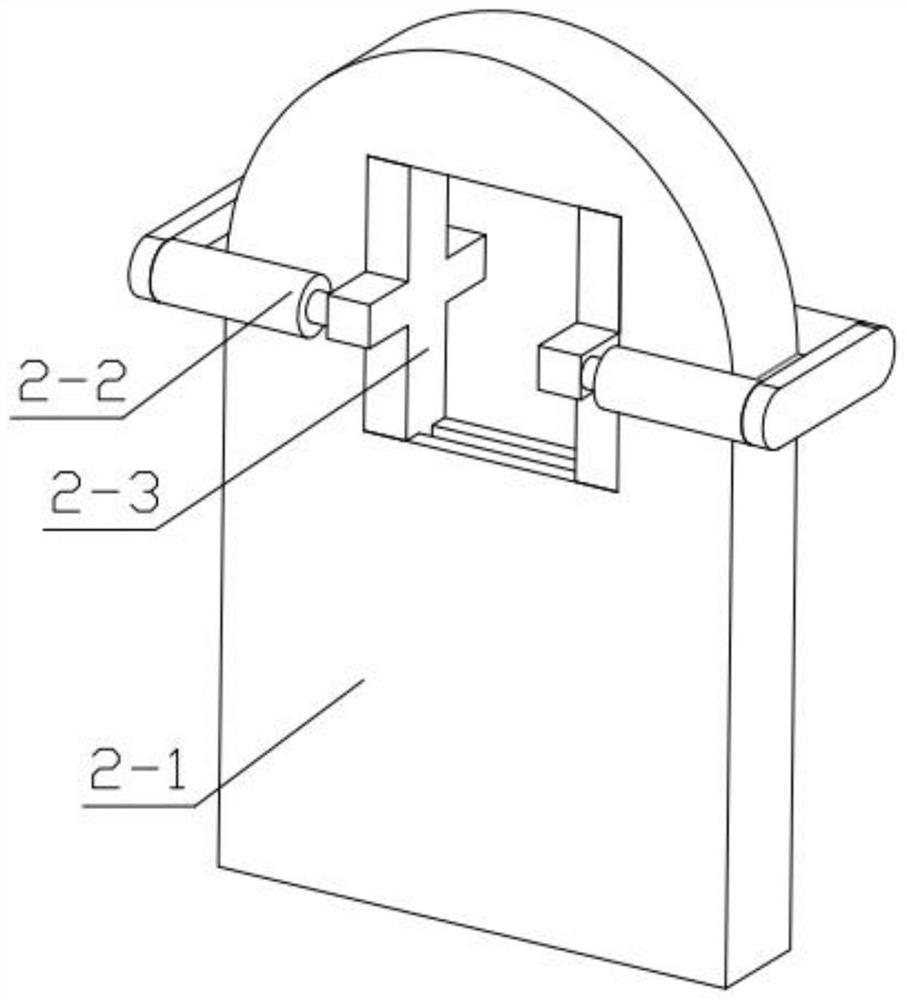

[0032] Combine below Figure 1-13 Describe this embodiment, this embodiment will further explain the first embodiment, the positioning mechanism 2 includes a vertical plate 2-1, a hydraulic cylinder 2-2, a clamping slider 2-3, and the vertical plate 2-1 is fixedly installed On the base 1, the hydraulic cylinder one 2-2 is fixedly installed on the vertical plate 2-1, the output end of the hydraulic cylinder one 2-2 is fixedly installed with a clamping slide 2-3, and the clamping slide 2-3 is slidably installed In the groove provided on the riser 2-1.

specific Embodiment approach 3

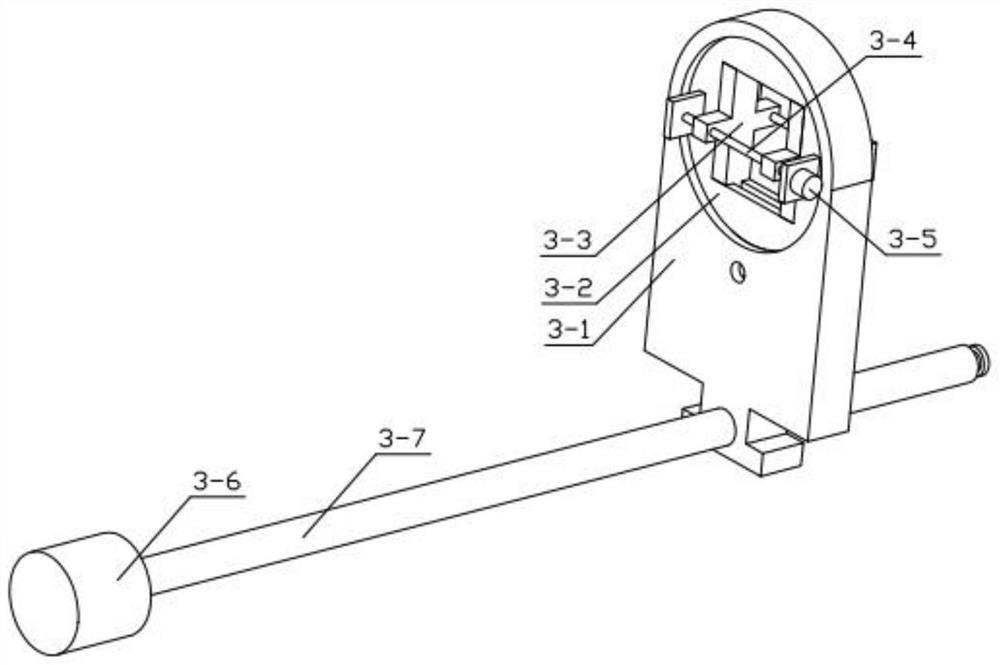

[0033] Combine below Figure 1-13 Describe this embodiment, this embodiment will further explain the first embodiment, the broken force mechanism 3 includes a moving slide 3-1, an inner rotating disk 3-2, a cross clamping plate 3-3, a short two-way threaded rod 3- 4. Clamping motor 3-5, spacing adjustment motor 3-6, long two-way threaded rod 3-7, synchronous sprocket 1 3-8, synchronous chain 3-9, synchronous sprocket 2 3-10, spacing adjustment motor 3 -6 is fixedly installed on the base 1, and the output end of the spacing adjustment motor 3-6 is fixedly installed with a long two-way threaded rod 3-7, and the long two-way threaded rod 3-7 is rotatably installed in the groove provided on the base 1, and the long two-way The threaded rod 3-7 is threadedly connected with the mobile slide plate 3-1, the mobile slide plate 3-1 is slidably installed in the groove provided on the base 1, and the inner rotating disc 3-2 is rotatably installed in the groove provided on the mobile slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com