Chitosan polycation composite material reducing phenols materials in cigarette smoke

A composite material, cigarette smoke technology, applied in the direction of tobacco, smoke oil filter, food science, etc., can solve the problems of increasing harmful components, complicated preparation process, influence of smoke taste, etc., to reduce harmful phenolic components, maintain internal Quality, effect to avoid loss of aroma components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

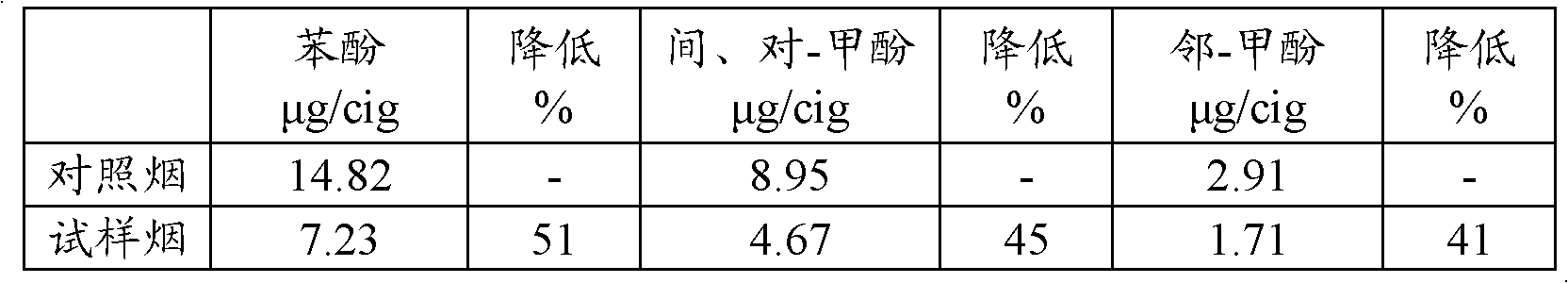

[0038] A solution of 5 mg / mL chitosan hydrochloride (solution A) and a solution of 5 mg / mL sodium polystyrene sulfonate (solution B) were prepared. Take 5.0g of granular activated carbon, mix it with 10ml of solution B, stir evenly, and let it stand at 25°C for 1h. Filter and bake all the solids at 70°C for 48h. The obtained solid was mixed with 10 mL of solution A, stirred evenly, and allowed to stand at 25° C. for 1 h. Filtrate, dry all the solids at 80°C for 40 hours to obtain dry solids, that is, to complete one self-assembly, and then treat the dry solids with solution B and solution A for 6 times according to the above method, and obtain 14 monolayers. The outer layer is the above-mentioned hydrophilic polycation of chitosan hydrochloride to obtain a composite material with high water retention, and the mass percent content of the polycation loaded in the composite material is 3%. In the infrared spectrum of the composite material, 1000~1100cm -1The appearance of the ...

Embodiment 2

[0045] Chitosan hydrochloride was dissolved in water to prepare an aqueous solution of 0.2 mg / mL chitosan hydrochloride (solution A) and an aqueous solution of 8 mg / mL sodium alginate (solution B). Take 5.0g of powdered silica gel, mix it with 10ml of solution B, stir evenly, and let stand at 15°C for 2h. Filter and bake all the solids at 60°C for 72h. The obtained solid was mixed with 5 mL of solution A, stirred evenly, and allowed to stand at 25° C. for 1 h. Filtrate and dry the filtered solid at 75°C for 50 hours to obtain a dry solid, that is, to complete one self-assembly, and then treat the dry solid with solution B and solution A for 10 times according to the above method to obtain 22 monolayers, The outermost layer is the above-mentioned chitosan hydrochloride hydrophilic polycation, and the composite material with high water retention can be obtained (1000~1100cm in the infrared spectrum -1 The appearance of the characteristic peak at the place, and the measured val...

Embodiment 3

[0052] Chitosan hydrochloride was dissolved in water to prepare an aqueous solution of 10 mg / mL chitosan hydrochloride (solution A) and an aqueous solution of 4 mg / mL carboxymethyl chitosan (solution B). Take 5.0g granular macroporous adsorption resin, mix it with 4ml solution B, stir evenly, and let stand at 25°C for 2h. Filter and bake all the solids at 60°C for 72h. The obtained solid was mixed with 4 mL of solution A, stirred evenly, and allowed to stand at 30° C. for 1 h. Filtrate and dry the filtered solid at 75°C for 50 hours to obtain a dry solid, that is, to complete one self-assembly, and then treat the dry solid with solution B and solution A for 7 times according to the above method to obtain 16 monolayers, The outermost layer is the above-mentioned chitosan hydrochloride hydrophilic polycation to obtain a composite material with high water retention, and the weight percentage of polycation loaded in the composite material is 3%. In the infrared spectrum of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com