Combined small high-efficiency coating machine

A coating machine and combined technology, which is used in the fields of making medicines into special physical or ingestible devices, food shaping, food science, etc., which can solve waste, increase costs, occupy an area, and invest heavily in equipment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

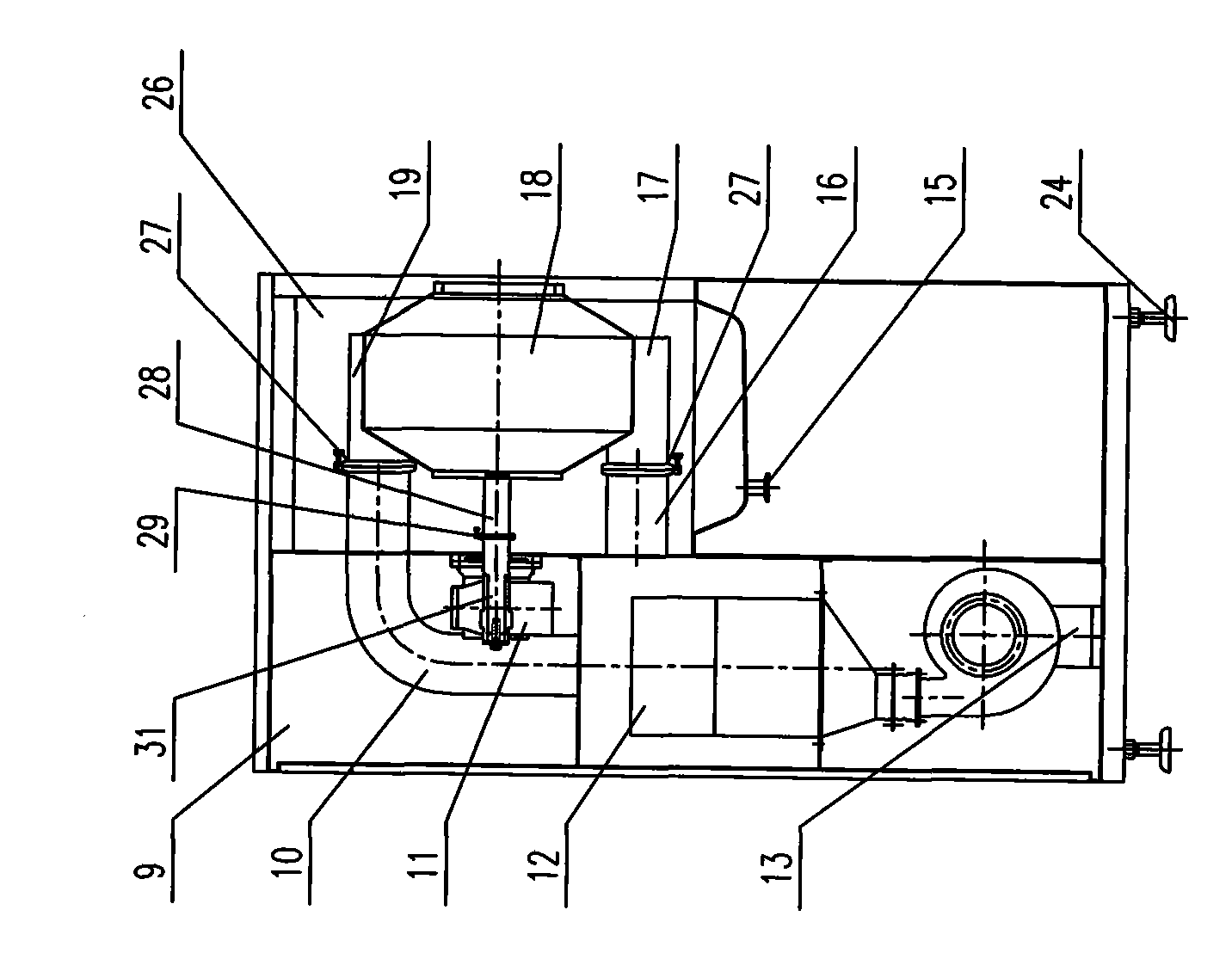

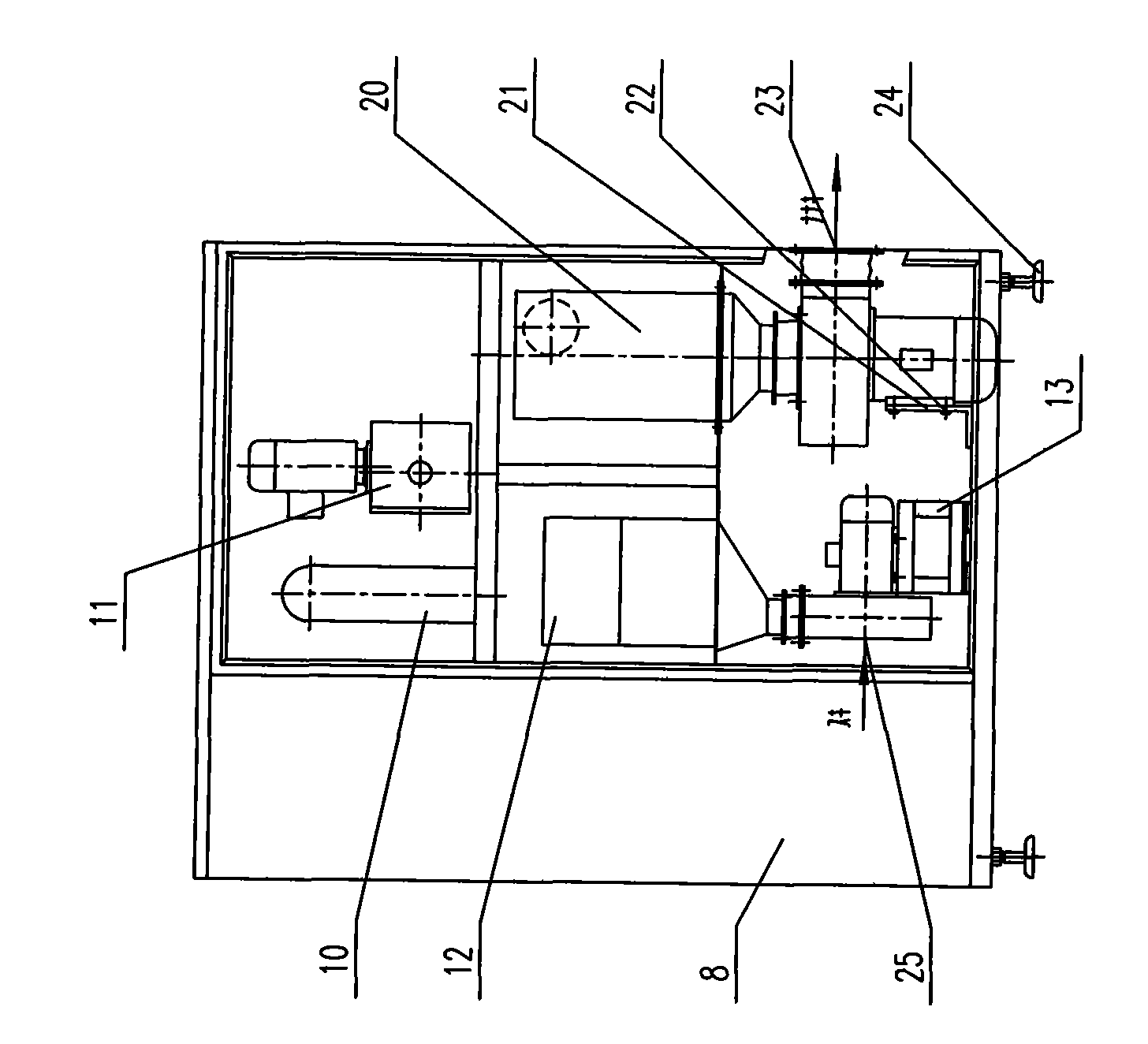

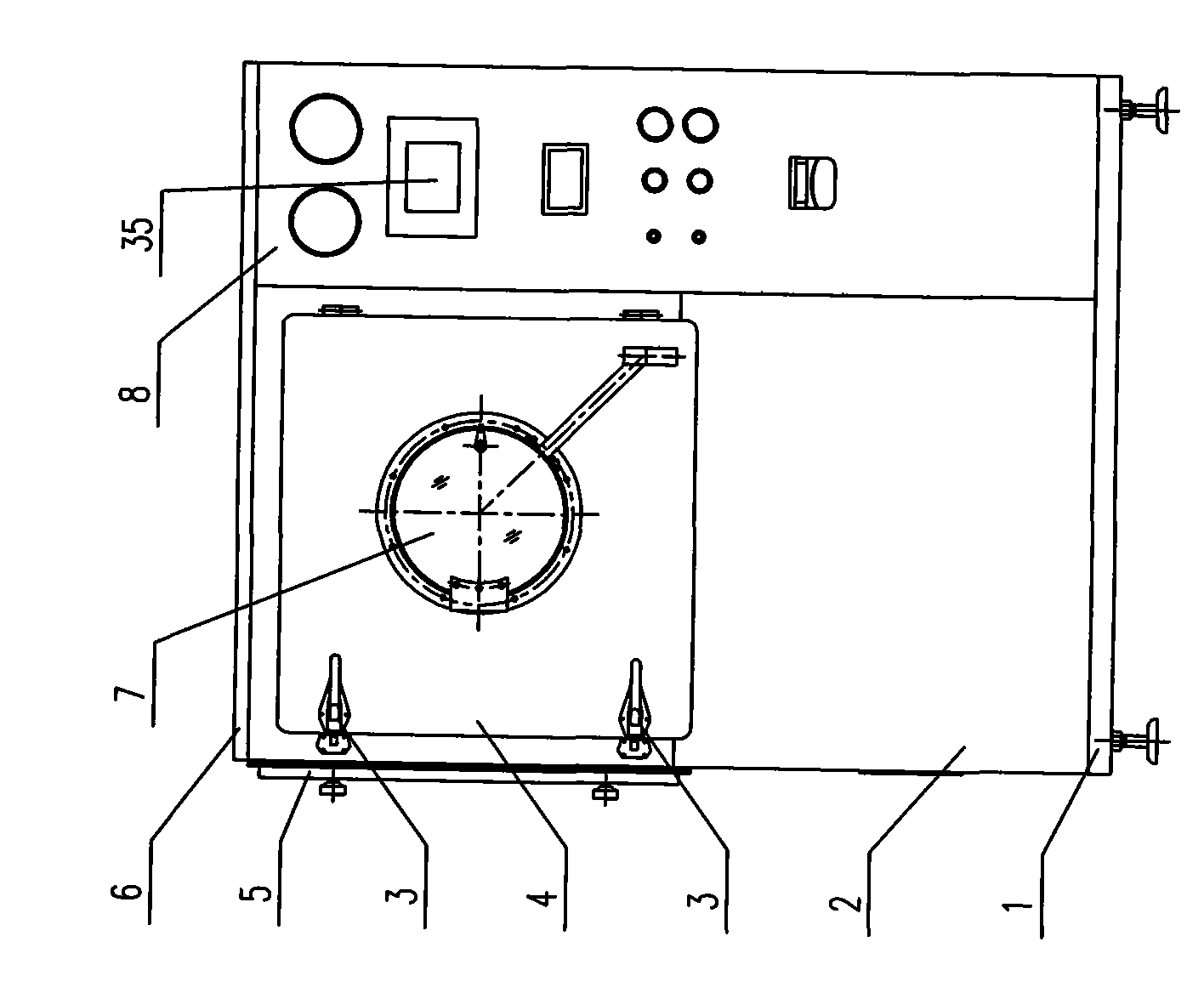

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 In the shown embodiment, the host machine 2 is provided with a front box body 26 for mainly placing the coating drum 18 and a rear box body 9 for mainly installing the transmission reducer 11 which are separated from each other, and the rear box body 9 is provided with a built-in high-efficiency filter hot air blower 12 , dust removal exhaust fan 20 and the electric control box 8 that contains the microcomputer automatic control operating system, the high-efficiency filter hot air fan 12 and the dust removal exhaust fan 20 are respectively installed on the hot air fan support 13 and the exhaust fan support 21 that are positioned at the bottom of the rear box body 9, and the electric Control box 8 places rear box body one side position, and front and back box body bottom is equipped with movable caster 34 or fixed support foot 24. The transmission reducer 11 is connected with the drum main shaft 28 of the coating dru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com