High treatment capacity feed atomizing nozzle

A technology of atomizing nozzles and processing capacity, which is applied in the direction of chemical/physical/physical-chemical nozzle reactors, injection devices, liquid injection devices, etc., which can solve the difficulties in the layout of process pipelines and on-site operations, and the inability to arrange all nozzles in risers, The strength of the riser is difficult to produce safely, and the effects of high anti-wear performance, low dry gas production rate and moderate injection speed are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

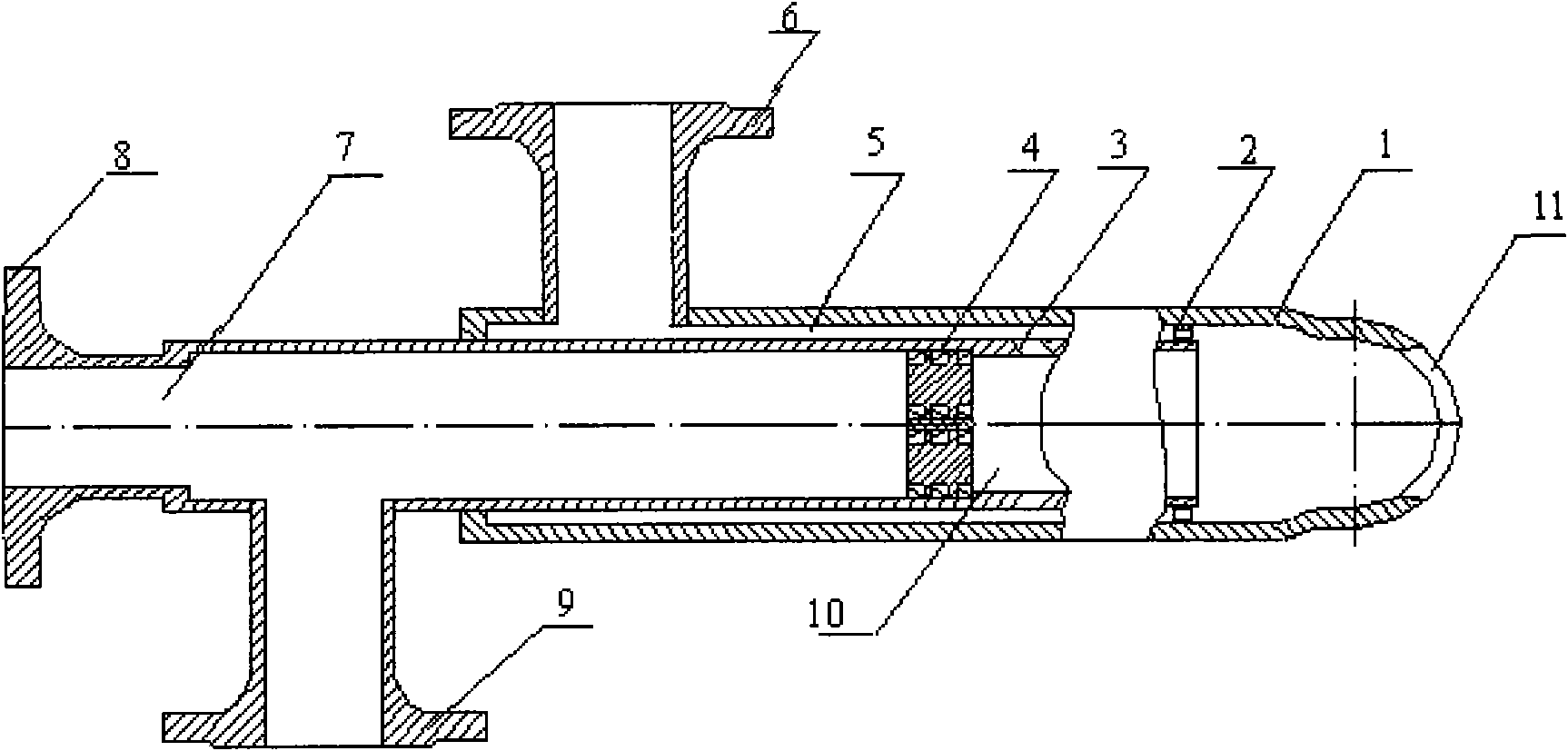

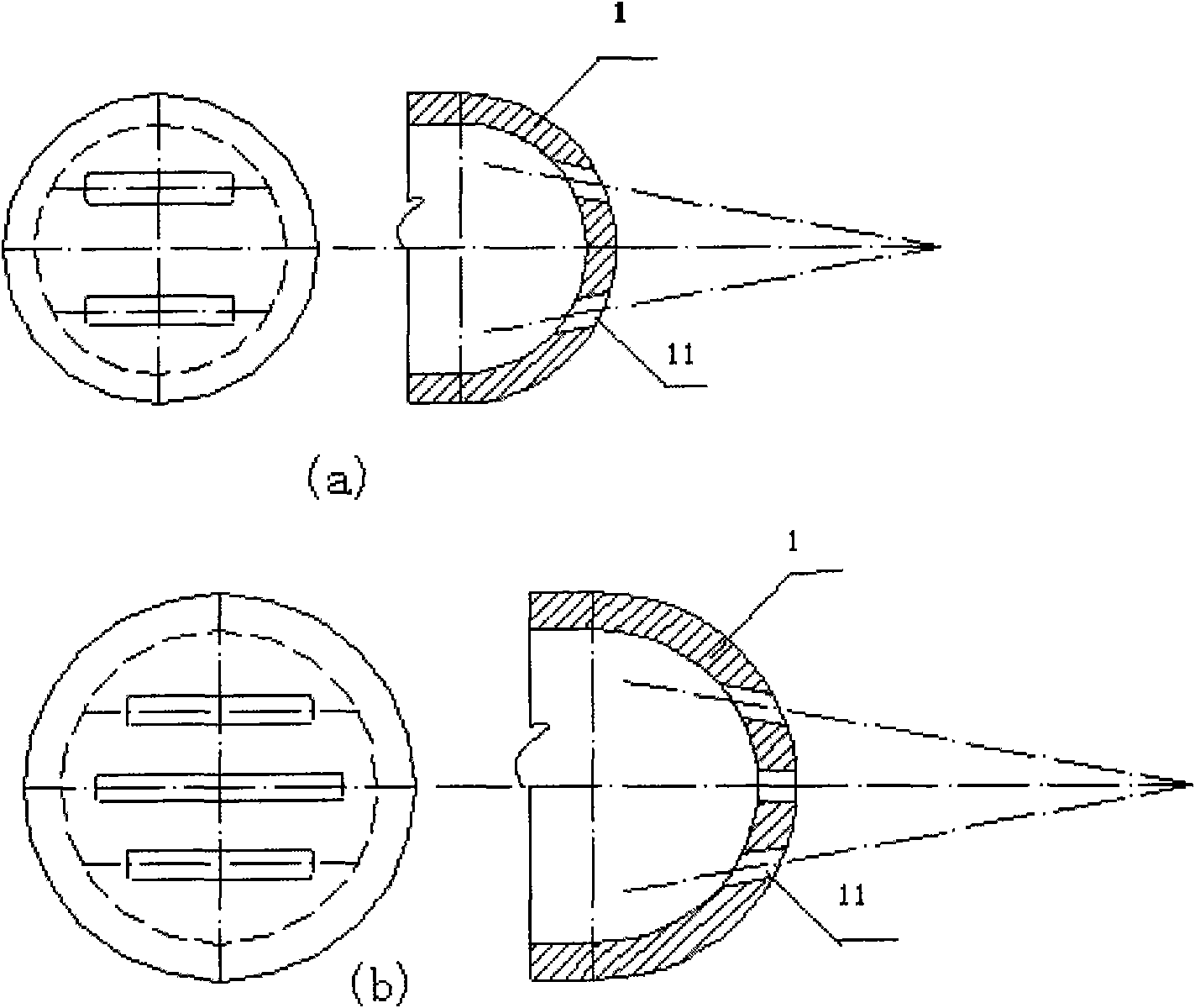

[0034] Such as figure 1 As shown, a large-capacity feed atomization nozzle includes a primary air intake pipe and a secondary air intake pipe, and the central axis of the two is on the same line as the central axis of the nozzle; the secondary air intake pipe is sleeved on the primary The outer side of the air intake pipe, the jacket space therebetween forms a secondary air intake chamber 5; the primary air intake pipe includes an air inlet 8, an oil inlet 9, a mixing chamber 7 and an injection pipe 10; the secondary air intake pipe includes Secondary air inlet 6, nozzle 1 and nozzle hole 11.

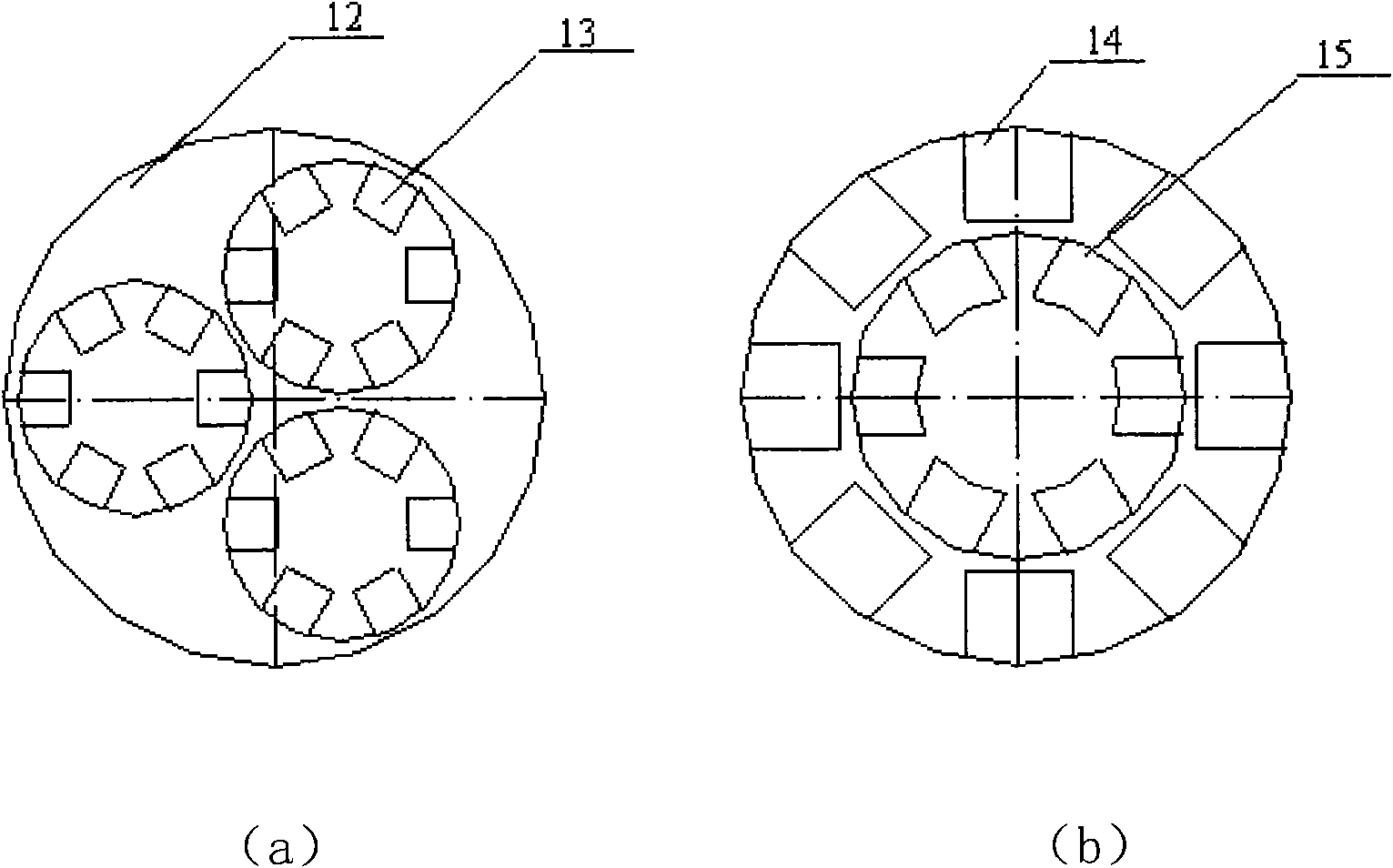

[0035] A combined swirler 4 is installed between the mixing chamber 7 and the injection pipe 10 in the primary air intake pipe, and the combined swirler includes a group of small-diameter swirlers.

[0036] The nozzle adopts a multi-point gas injection structure, that is, a group of secondary air holes 3 are opened on the wall of the injection pipe 10 in the primary air intake pipe, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com