Electric arc welder

An arc welding machine and circuit technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of high material costs and complex structures, and achieve improved workability, improved welding quality, and good arc disconnection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

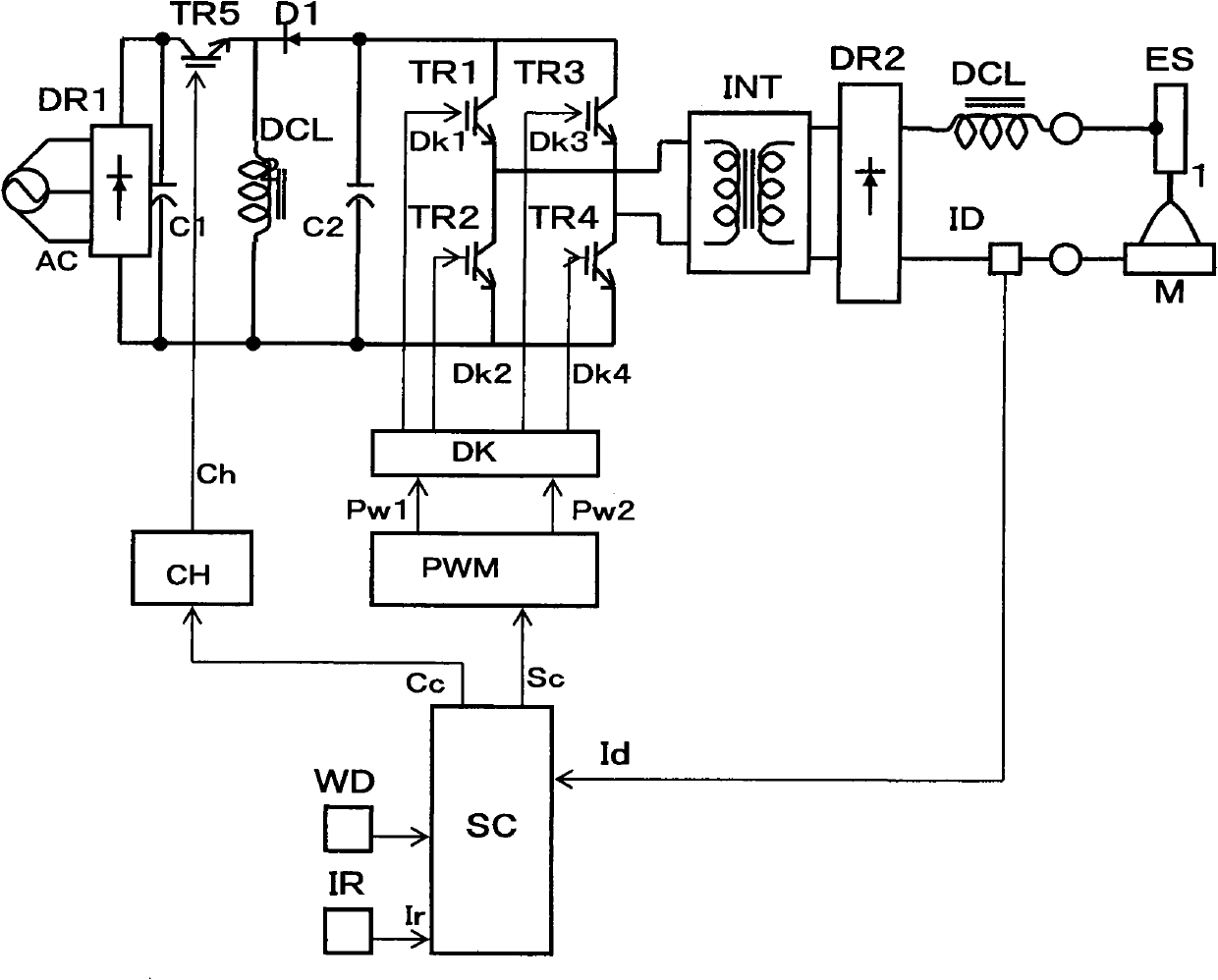

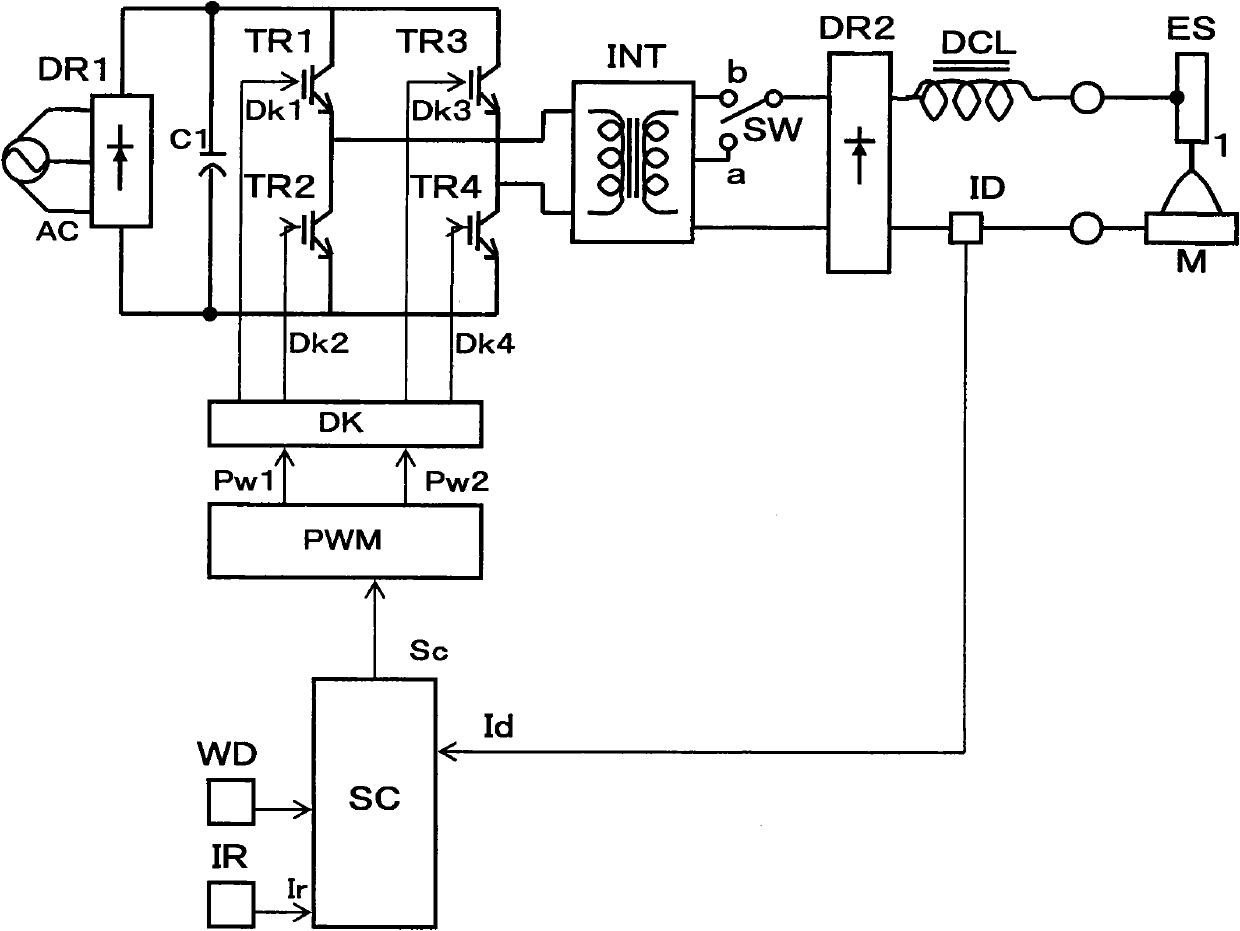

[0032] figure 1 It is an electric connection diagram of the arc welder of Embodiment 1. exist figure 1 in, with Figure 8 In the electrical connection diagram of the conventional arc welding machine shown, components with the same symbols operate in the same manner, so descriptions are omitted, and only components with different symbols will be described.

[0033] figure 1 The selection circuit WD shown selects either the spot welding mode or the no spot welding mode. The output current setting circuit IR sets a predetermined output current setting signal Ir.

[0034] When the spot welding mode is selected by the selection circuit WD, the main control circuit SC outputs the spot welding mode signal Wc, and performs a comparison operation on the value of the output current setting signal Ir and the value of the output current detection signal Id to output a comparison operation signal Sc .

[0035] figure 1 The shown pulse width modulation circuit PWM performs PWM con...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap