Parallel-connected torque control system and method for hydraulic hybrid power vehicles

A hybrid power system and hybrid vehicle technology, applied in the direction of automatic steering control components, vehicle components, steering mechanisms, etc., can solve the problems of unreasonable energy distribution and inability to optimize the fuel economy of the whole vehicle, so as to avoid adverse effects, Best fuel economy and high reliability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

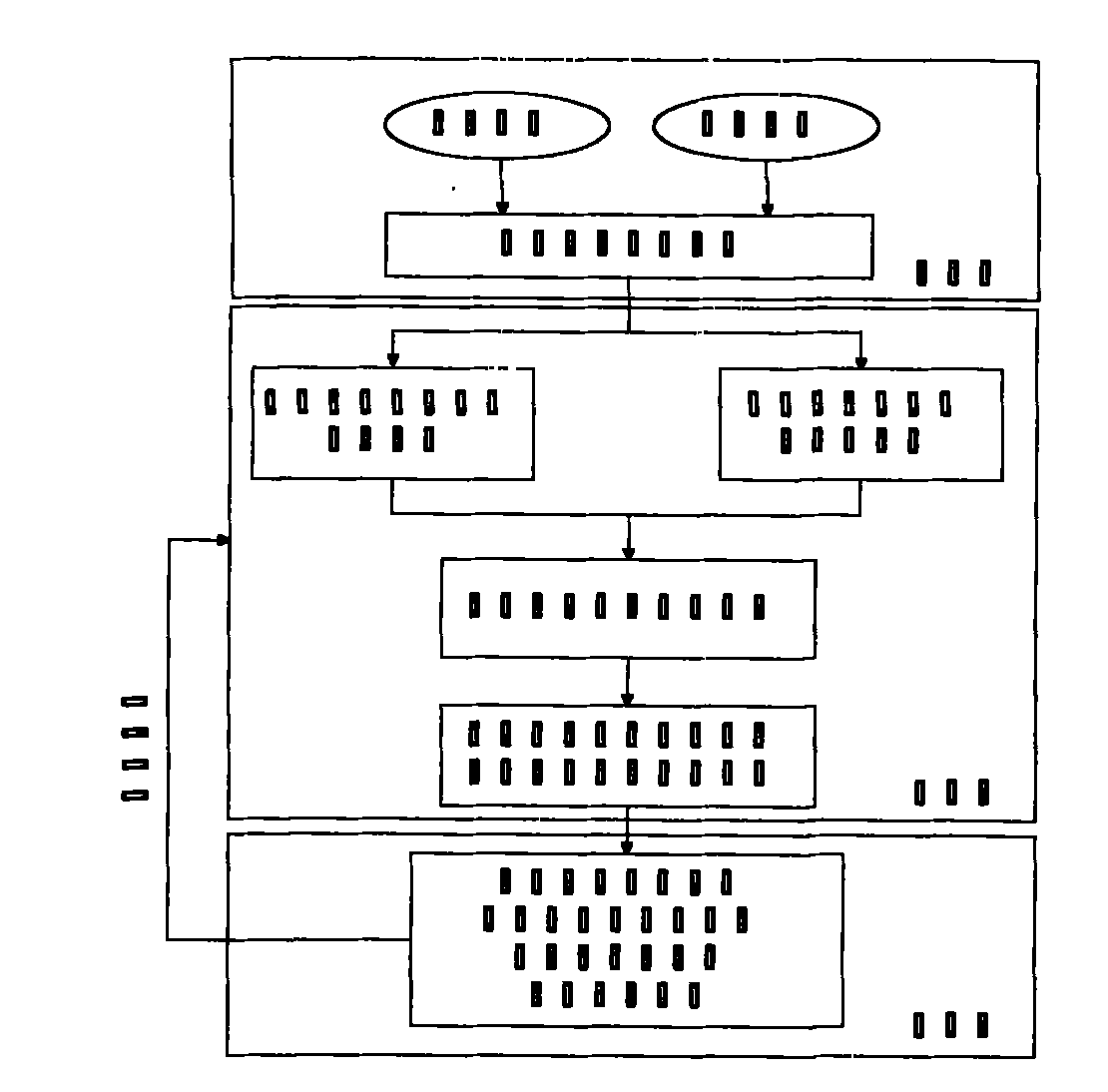

[0034] Embodiment 1: The control system and method include a hydraulic hybrid vehicle control method and a hydraulic hybrid vehicle torque control system;

[0035] Control methods for hydraulic hybrid vehicles:

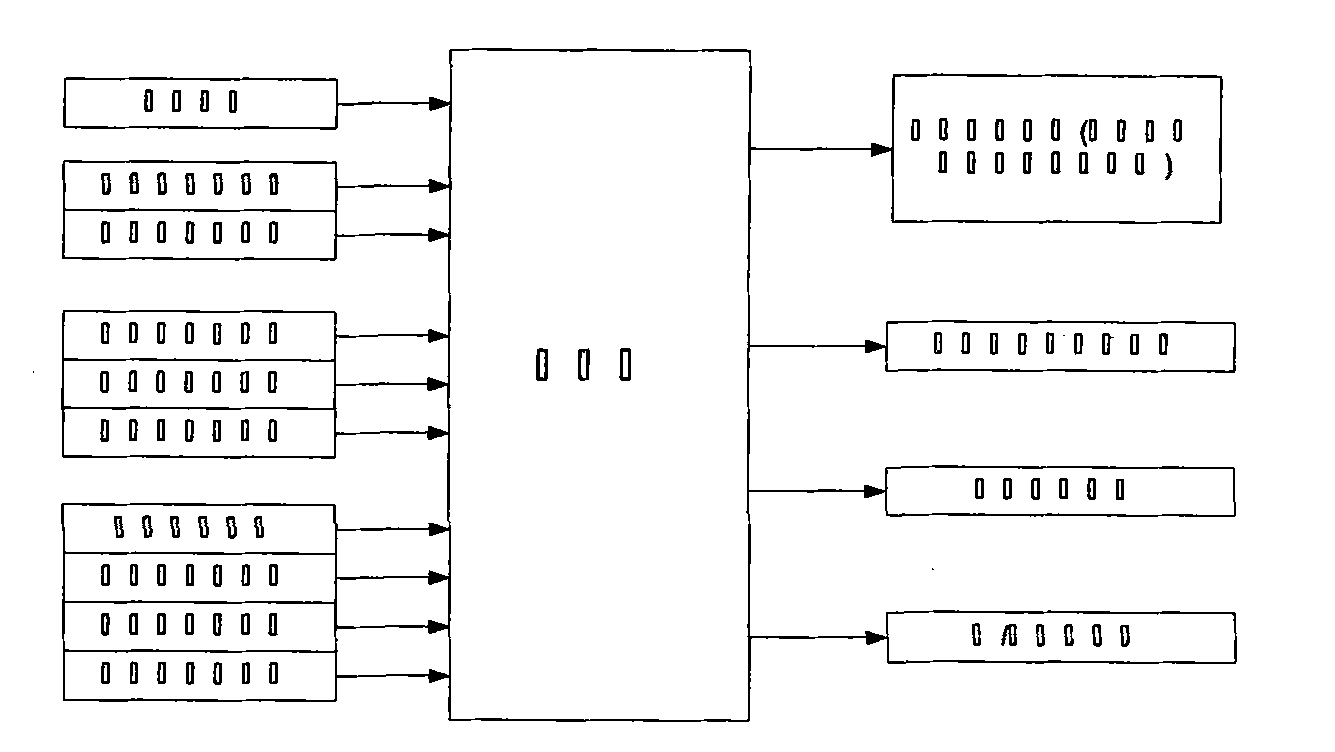

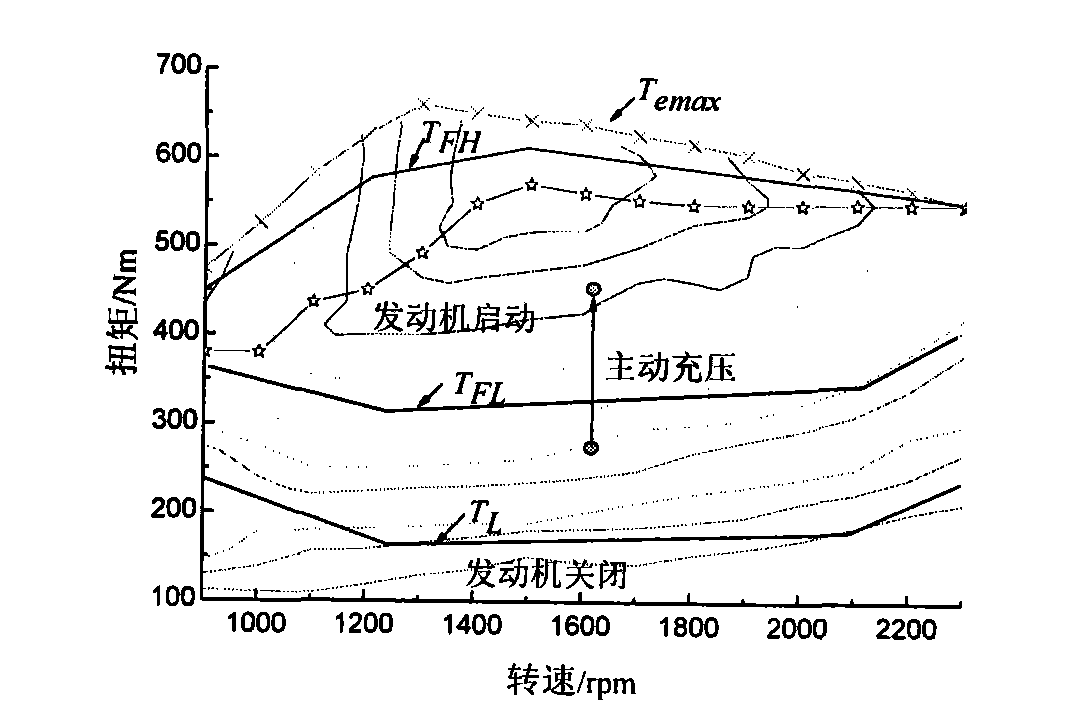

[0036] (1) According to the driver's operation behavior on the accelerator pedal, combined with the vehicle speed in the current state, determine the vehicle drive target torque of the vehicle in the current state, the estimation of the torque of the hydraulic hybrid power system in the current state, and the target torque of the hybrid power system Determination of output torque, engine target output torque command and hydraulic pump motor target output torque command;

[0037] The method for realizing the vehicle driving target torque is: according to the opening degree of the accelerator pedal and the pedal change rate, it is converted into the target driving torque of the vehicle at different speeds and different gears;

[0038] The method for estimating the torq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com