Method for preparing partially stabilized zirconia ceramics by adopting natural baddeleyite

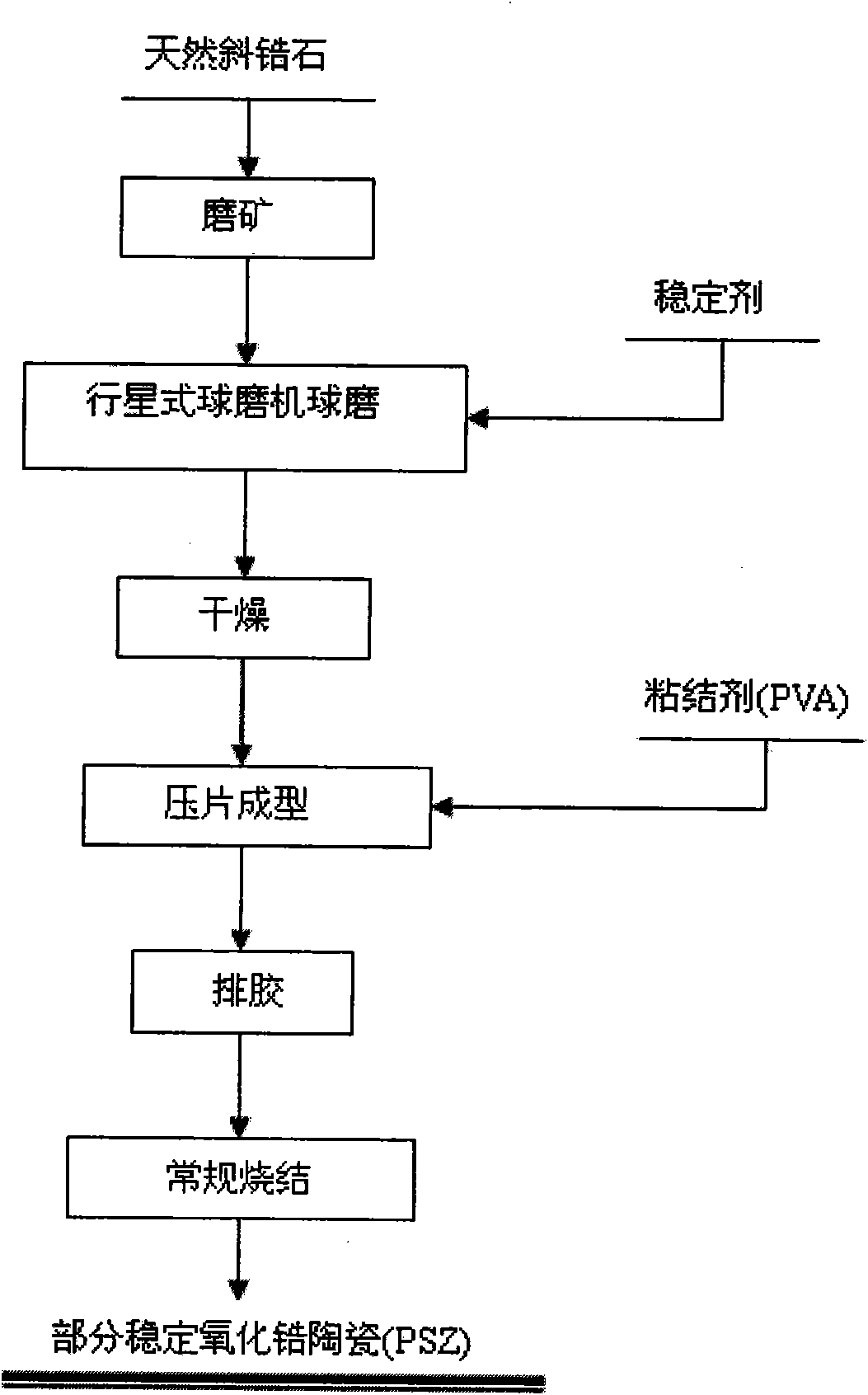

A technology for stabilizing zirconia and baddeleyite is applied in the field of natural baddeleyite to prepare partially stabilized zirconia ceramics, and natural zirconia is used as raw material to directly prepare zirconia ceramics, which can solve the problems of prolonging production process, increasing cost, pollution and the like, To achieve the effect of short process flow, harmless treatment and lower energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

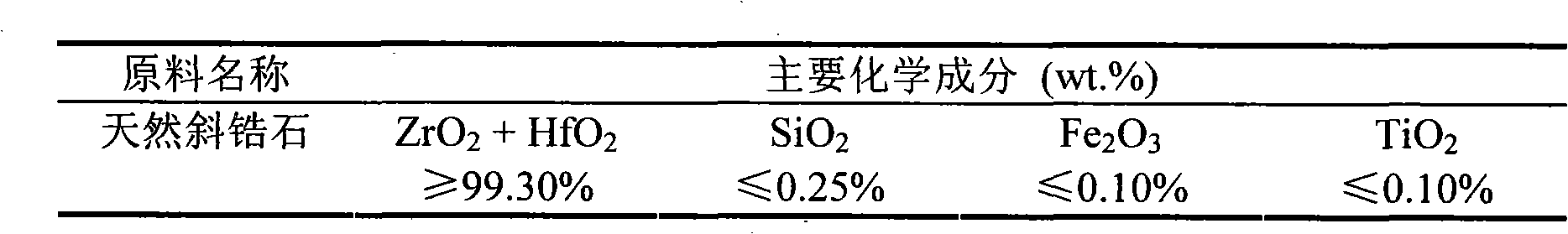

[0017] Weigh natural zirconia and crush it, and the average particle size of particle size grinding to 5.67 μm accounts for 50% of the total amount. The natural zirconia of 3.0wt.% MgO is moved into an agate ball mill jar, and ball milled for 24 hours with a planetary ball mill (rotating speed 250 rpm), the dispersant is alcohol, and the amount added is twice the mass of the material. After ball milling, the material is taken out, dried at 80°C for 6 hours, and the alcohol in the material is removed, and 3wt.% is added to the dried material The binder polyethylene glycol is mixed and stirred for 30 minutes to make the materials evenly mixed, and then formed into a round cake-shaped material under a uniaxial pressure of 100 MPa, and then deglue at 850 ° C, keep it warm for 1 hour, and the heating rate is 5°C / min, after debinding, the heating rate was 4°C / min to 1500°C for sintering and heat preservation for 4 hours, and the cooling rate was 8°C / min to room temperature, and final...

Embodiment 2

[0019] Weigh the natural zirconia for crushing, and grind the particle size until the average particle size of 7.76 μm accounts for 50% of the total amount. Move the natural zirconia added with 4.5wt.% dose of MgO stabilizer into an agate ball mill jar, and use a planetary ball mill for ball milling for 12 hours (rotating speed 350 rev / min), dispersant is alcohol, and the addition amount is 2.5 times of material mass, takes out material after ball milling, and dries at 100 ℃ for 6 hours, removes the alcohol in the material, and adds 3.5 to the material after drying. wt.% binder PVA (polyethylene glycol), mixed and stirred for 40 minutes to make the materials evenly mixed, and formed into a round cake under a uniaxial pressure of 150MPa; The rate is 3°C / min. After debinding, the heating rate is 6°C / min to 1550°C for sintering and heat preservation for 5 hours, and the cooling rate is 10°C / min to room temperature, and finally a partially stable zirconia ceramic product is obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com