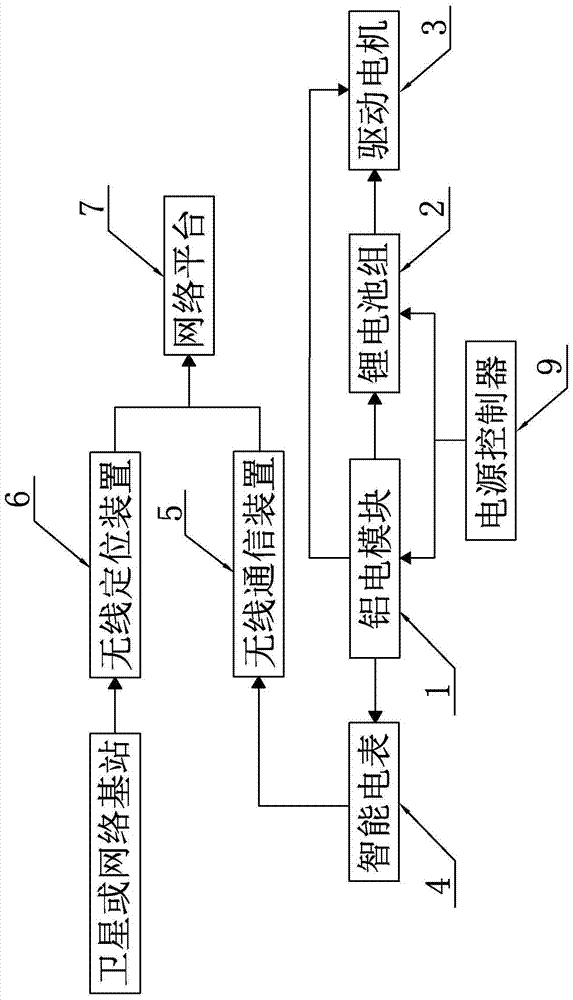

Vehicle Aluminum Electric Module Power Supply System

A power supply system and electric module technology, applied in battery/battery traction, battery/fuel cell control devices, electric vehicles, etc., can solve the problems of electric vehicles such as inconvenient driving, increased cost and weight, and extended driving time. Various power supply forms, various installation methods, and easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

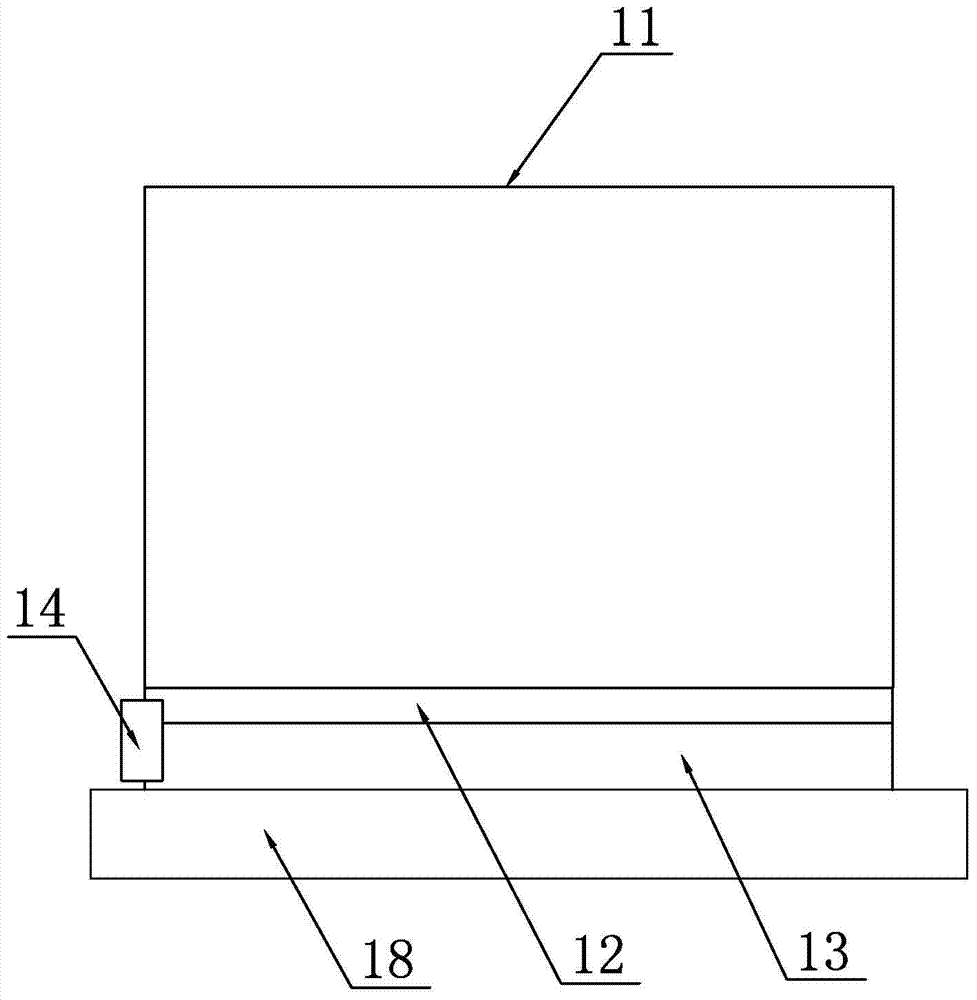

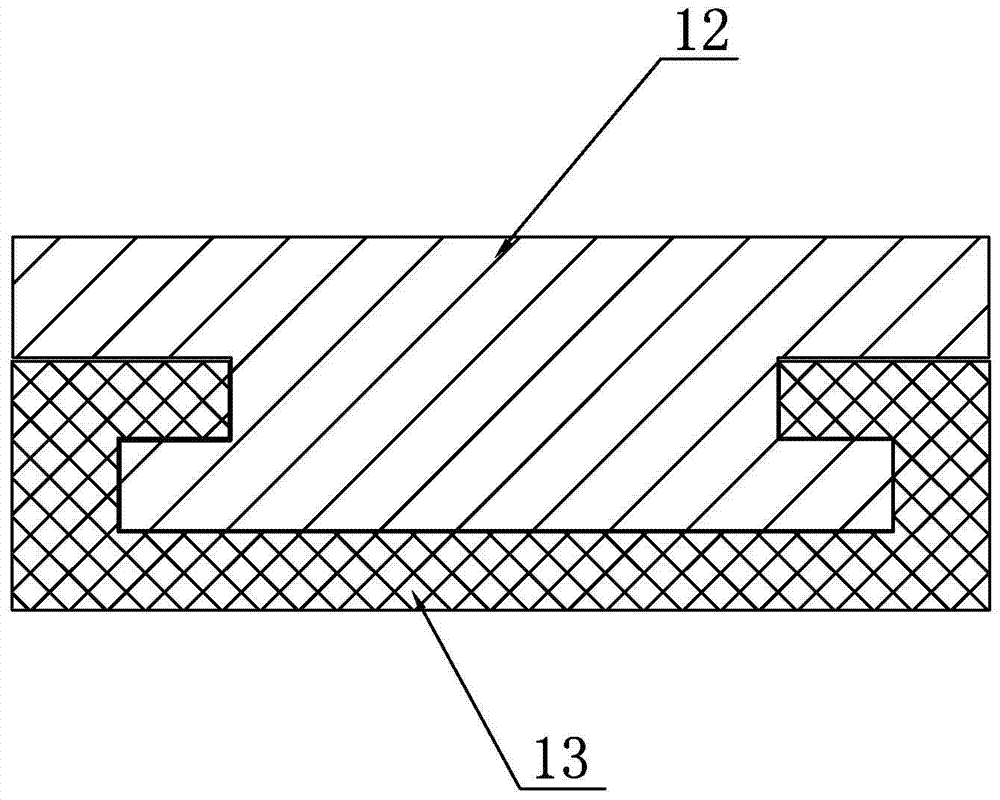

Embodiment 1

[0027] Embodiment 1: When the aluminum electric module 1 is fixedly installed in the bottom end or other positions inside the trunk of the electric vehicle along the horizontal direction, as figure 2 , image 3 As shown, it includes a housing 11, a first mounting seat 18 and a first locking member 14. The housing 11 is a cuboid structure, the aluminum electric module 1 is arranged inside the housing 11, the smart meter 4, the power controller 9, the wireless Both the communication device 5 and the wireless positioning device 6 are fixedly installed on the top of the casing 11 . A first guide rail 12 is installed along the horizontal direction at the bottom end of the housing 11, a first mounting seat 18 is arranged below the first guide rail 12, and a first guide groove 13 is provided on the top of the first mounting seat 18 along the horizontal direction. 12 is slid and inserted into the first guide groove 13 along the end of the first guide groove 13, the outer wall of the...

Embodiment 2

[0028] Embodiment 2: When the aluminum electric module 1 is fixedly installed at the bottom or other positions inside the trunk of the electric vehicle along the horizontal direction, as Figure 4 , Figure 5 , Figure 6As shown, it includes a housing 11 and a second mounting seat 20, the housing 11 is a cuboid structure, the aluminum electric module 1 is arranged inside the housing 11, the smart meter 4, the power controller 9, the wireless communication device 5 and the wireless positioning device 6 are all fixedly mounted on the top of the housing 11. Two cylindrical second guide grooves 21 are arranged side by side along the horizontal direction on the outer wall of the bottom end of the housing 11, and a second mounting seat 20 is arranged below the second guiding groove 21, and the top end of the second mounting seat 20 is arranged along the horizontal direction. Two first guide cones 22 are arranged side by side, and the ends on the same side of the two first guide co...

Embodiment 3

[0029] Embodiment 3: When the aluminum-electric module 1 is fixedly installed at the bottom or other positions inside the trunk of the electric vehicle along the horizontal direction, as Figure 7 , Figure 8 As shown, it includes a housing 11 and a fourth mounting seat 25, the housing 11 is a cuboid structure, the aluminum electric module 1 is arranged inside the housing 11, the smart meter 4, the power controller 9, the wireless communication device 5 and the wireless positioning device 6 are all fixedly mounted on the top of the housing 11. The positions on both sides of the bottom of the housing 11 are respectively provided with fixing plates 26 along the horizontal direction, and guide holes 28 are provided on the fixing plates. A fourth mounting seat 25 is arranged below the housing 11, and the positions on both sides of the top of the fourth mounting seat 25 are The third guide cone 27 is respectively arranged vertically, and the third guide cone 27 extends into the gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com