Functional high-polymer decorative composite material and preparation method thereof

A functional polymer and composite material technology, which is applied in the field of functional polymer decorative composite materials and its preparation, can solve problems such as difficult removal of harmful substances, and achieve the effect of improving air quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

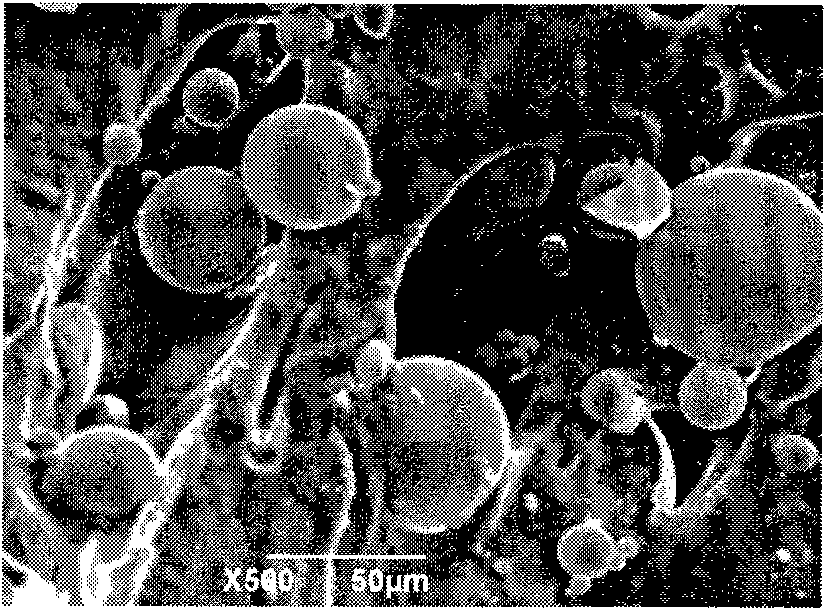

[0032] Take 10g of hollow glass microspheres and place them in a 500ml beaker, then add 20g of glycine powder, 150ml of water and 10ml of silane coupling agent, heat and stir in a water bath for 72 hours, the temperature of the water bath is 60°C, and the stirring rate is 20 rpm; The hollow microspheres are separated by centrifugation at a speed of 300 rpm, and then dried in an environment with a temperature of 80 ° C and a vacuum of 0.5 Pa, so that aminoacetic acid is loaded into the hollow glass microspheres to obtain Functional hollow microspheres capable of absorbing formaldehyde.

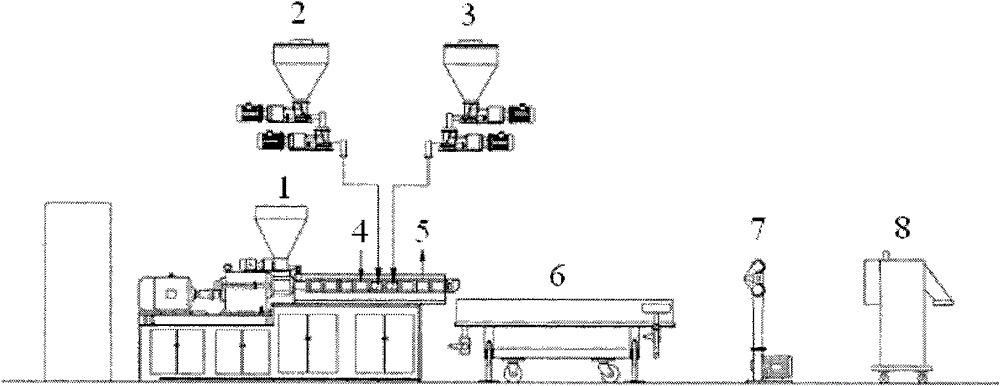

[0033] First, set the temperature of each section of the twin-screw extruder as follows: Zone 1 170°C, Zone 2 180°C, Zone 3 190°C, Zone 4 200°C, Zone 5 200°C, Zone 6 190°C, Zone 7 170°C. When the temperature of each section reaches the set temperature, the PP resin material is added from the main feeding port 1, and the functional hollow microspheres are added from the side feeding port 3. The ...

Embodiment 2

[0037] Take 10g of hollow ceramic microspheres and place them in a 500ml beaker, add 20g of lignin, 150ml of water and 10ml of silane coupling agent, then put the beaker into a vacuum chamber with a vacuum of 0.5MPa, heat and stir in a water bath for 72 hours, The temperature is 60°C, the stirring rate is 30 rpm; then the hollow microspheres are separated by centrifugation at a centrifugal speed of 300 rpm, and then dried at a temperature of 80°C and a vacuum of 0.5 Pa, thereby Lignin is loaded into hollow glass microspheres to obtain functional hollow microspheres capable of absorbing formaldehyde.

[0038] Pelletization using a staged side-feed twin-screw extruder, e.g. figure 2 shown in . The ABS resin material is added from the main feeding port 1, and the functional hollow microspheres are added from the side feeding port, that is, the hollow microsphere filling port 3, and the mass ratio of the added functional hollow microspheres to the ABS resin material is 2:3, The...

Embodiment 3

[0041] Take 5g of hollow silica microspheres and 5g of hollow glass microspheres and place them in a 500ml beaker, then add 15g of potassium sorbate powder, 15g of L-glutamic acid, 150ml of ethanol and 10ml of silane coupling agent, heat in a water bath and stir for 72 hours, The temperature of the water bath is 60°C, and the stirring rate is 40 rpm; then the hollow microspheres are separated by centrifugation at a centrifugal speed of 300 rpm, and then dried at a temperature of 60°C and a vacuum of 0.6Pa. Potassium sorbate and L-glutamic acid are thus loaded into the hollow glass microspheres to obtain functional hollow microspheres capable of absorbing formaldehyde.

[0042] Pelletization using a staged side-feed twin-screw extruder, e.g. figure 2 As shown in , the PP resin material is added from the main feeding port 1, and the functional hollow microspheres are added from the side feeding port. The mass ratio of the added functional hollow microspheres to the PP resin mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com