High temperature resistant reflective painting, preparation method thereof and reflector

A technology of reflective paint and high temperature resistance, applied in the field of paint, can solve the problems of no reflection, yellowing of paint, decrease in reflectivity, etc., and achieve the effects of high reflectivity, good adhesion and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

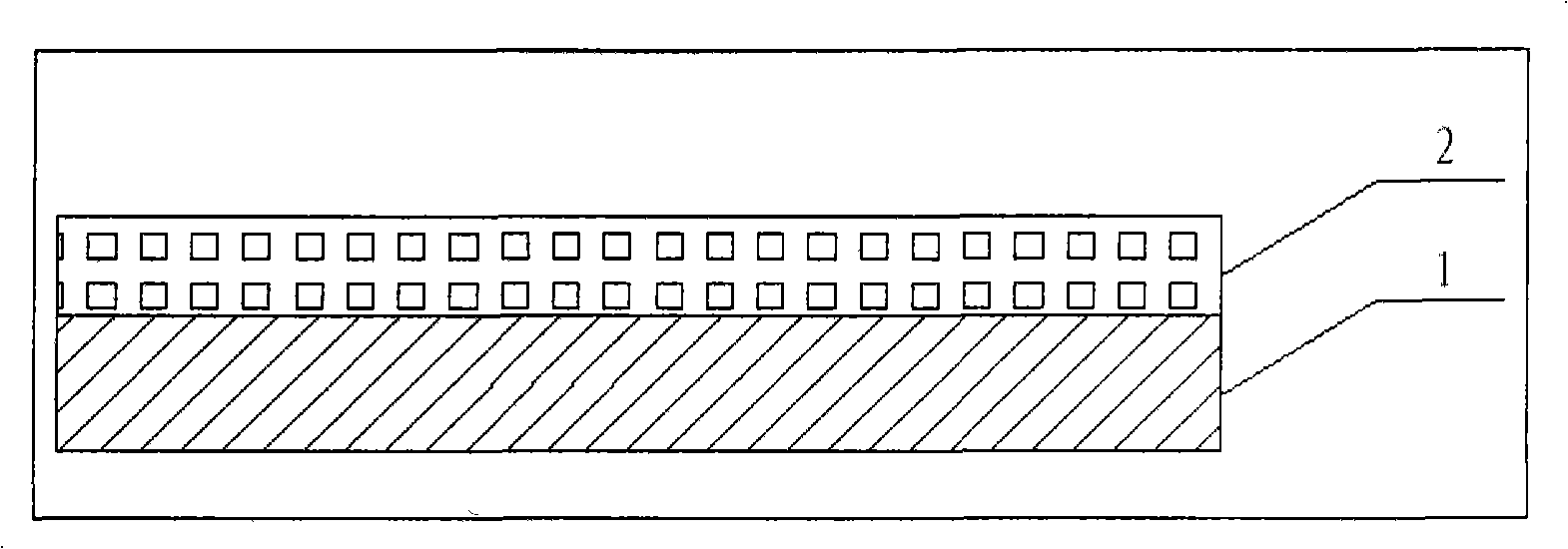

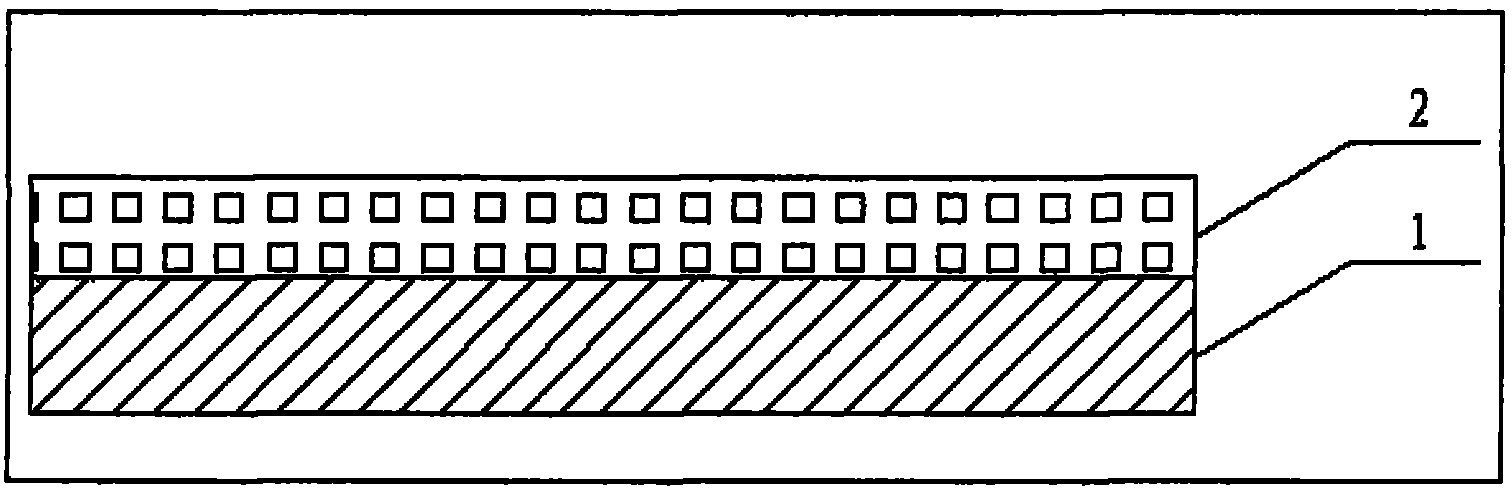

Image

Examples

Embodiment 1

[0055] (1) Prepare a 2000ml large beaker so that there is no water, no dust and no impurities in the beaker;

[0056] (2) First pour 300g of "Taiwan Zhenxiong" CT-882 (acrylic resin varnish) varnish into the prepared beaker, then add 600g of analytically pure 99% ZnO into it, and stir for 3 to 5 minutes;

[0057] (3) Add 30g of dispersant and stir thoroughly for 5-10 minutes until the material is uniform in white and there are no obvious granular objects on the stirrer.

[0058] (4) Add 30g of defoamer, 20g of leveling agent, and 20g of thickener, and stir thoroughly for 20 to 30 minutes until all materials are mixed evenly.

[0059] Among them: analytically pure ZnO is produced by Tianjin Fuchen Chemical Reagent Factory, leveling agent, thickener, defoamer and dispersant are polyurethane leveling agent Rm-2020, associative thickener produced by Guangzhou Guanzhi Chemical Co., Ltd. Thickener TT-935, defoamer BEF-760 and dispersant CF-10.

[0060] The physical properties of t...

Embodiment 2

[0072] (1) Prepare a 2000ml large beaker so that there is no water, no dust and no impurities in the beaker;

[0073] (2) First pour 300g of "Taiwan Zhenxiong" CT-882 (acrylic resin varnish) varnish into the prepared beaker, then add 500g of analytically pure 99% ZnO into it, and stir for 3 to 5 minutes;

[0074] (3) Add 60g of dispersant and stir thoroughly for 5-10 minutes until the material is white and uniform, and there are no obvious granular objects on the stirrer.

[0075] (4) Add 60g of defoamer, 40g of leveling agent, and 40g of thickener, and stir thoroughly for 20 to 30 minutes until all materials are evenly mixed.

[0076] Among them: analytically pure ZnO is produced by Tianjin Fuchen Chemical Reagent Factory, leveling agent, thickener, defoamer and dispersant are polyurethane leveling agent Rm-2020, associative thickener produced by Guangzhou Guanzhi Chemical Co., Ltd. Thickener TT-935, defoamer BEF-760 and dispersant CF-10.

Embodiment 3

[0078] (1) Prepare a 2000ml large beaker so that there is no water, no dust and no impurities in the beaker;

[0079] (2) First pour 300g of "Taiwan Zhenxiong" CT-882 (acrylic resin varnish) varnish into the prepared beaker, then add 640g of analytically pure 99% ZnO into it, and stir for 3 to 5 minutes;

[0080] (3) Add 20g of dispersant and stir thoroughly for 5-10 minutes until the material is uniform in white and there are no obvious granular objects on the stirrer.

[0081] (4) Add 20g of defoamer, 10g of leveling agent, and 10g of thickener, and stir thoroughly for 20 to 30 minutes until all materials are mixed evenly.

[0082] Among them: analytically pure ZnO is produced by Tianjin Fuchen Chemical Reagent Factory, leveling agent, thickener, defoamer and dispersant are polyurethane leveling agent Rm-2020, associative thickener produced by Guangzhou Guanzhi Chemical Co., Ltd. Thickener TT-935, defoamer BEF-760 and dispersant CF-10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com