Device for preparing combustible gas from plant material at high temperature

A plant material, high temperature technology, used in special forms of dry distillation, petroleum industry, coke ovens, etc., can solve the problems of incomplete catalytic cracking of plant materials, unfavorable disassembly and replacement of electric heating plates, affecting catalytic cracking of plant materials, etc. Simple structure, safe and reliable use, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

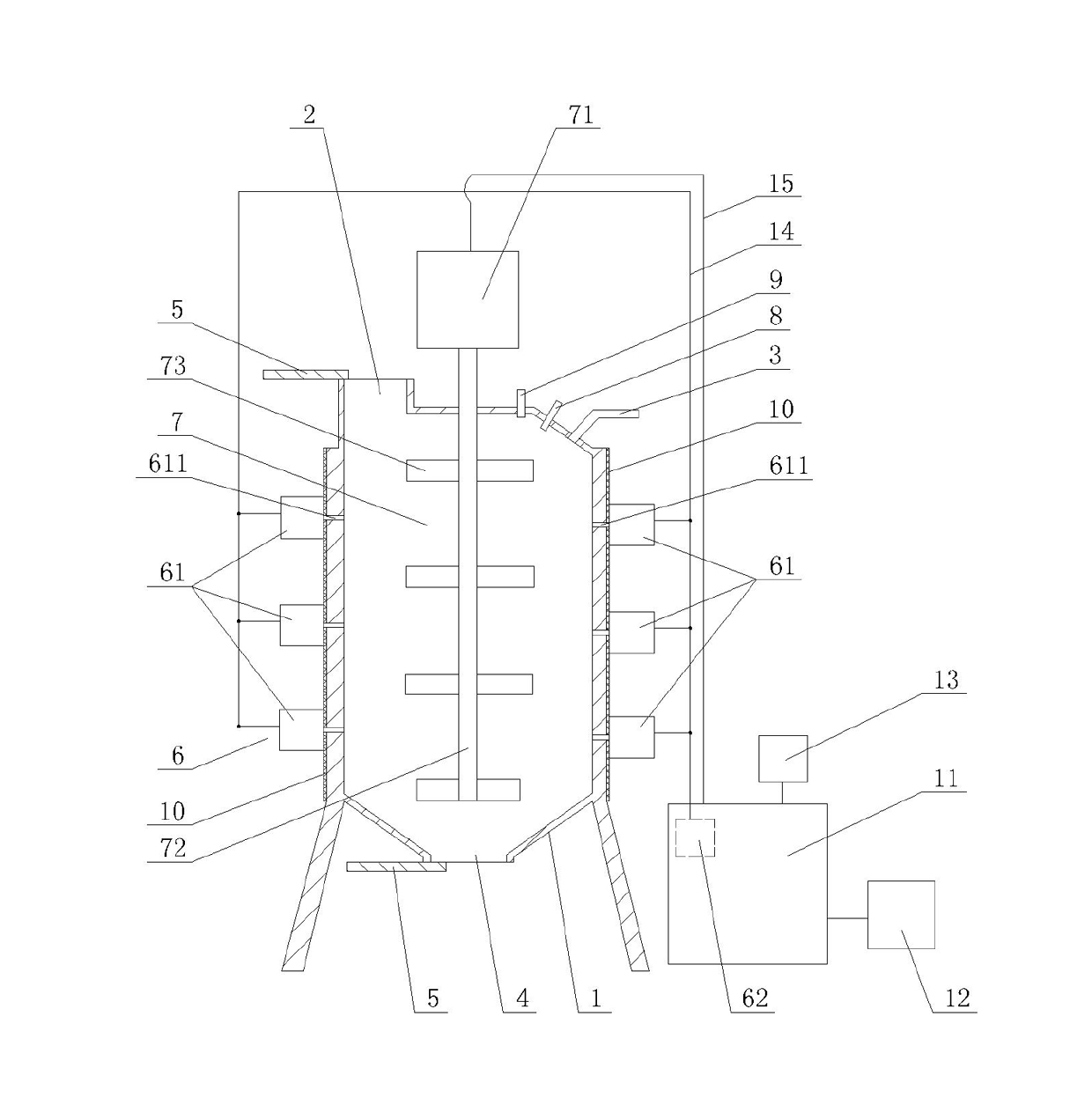

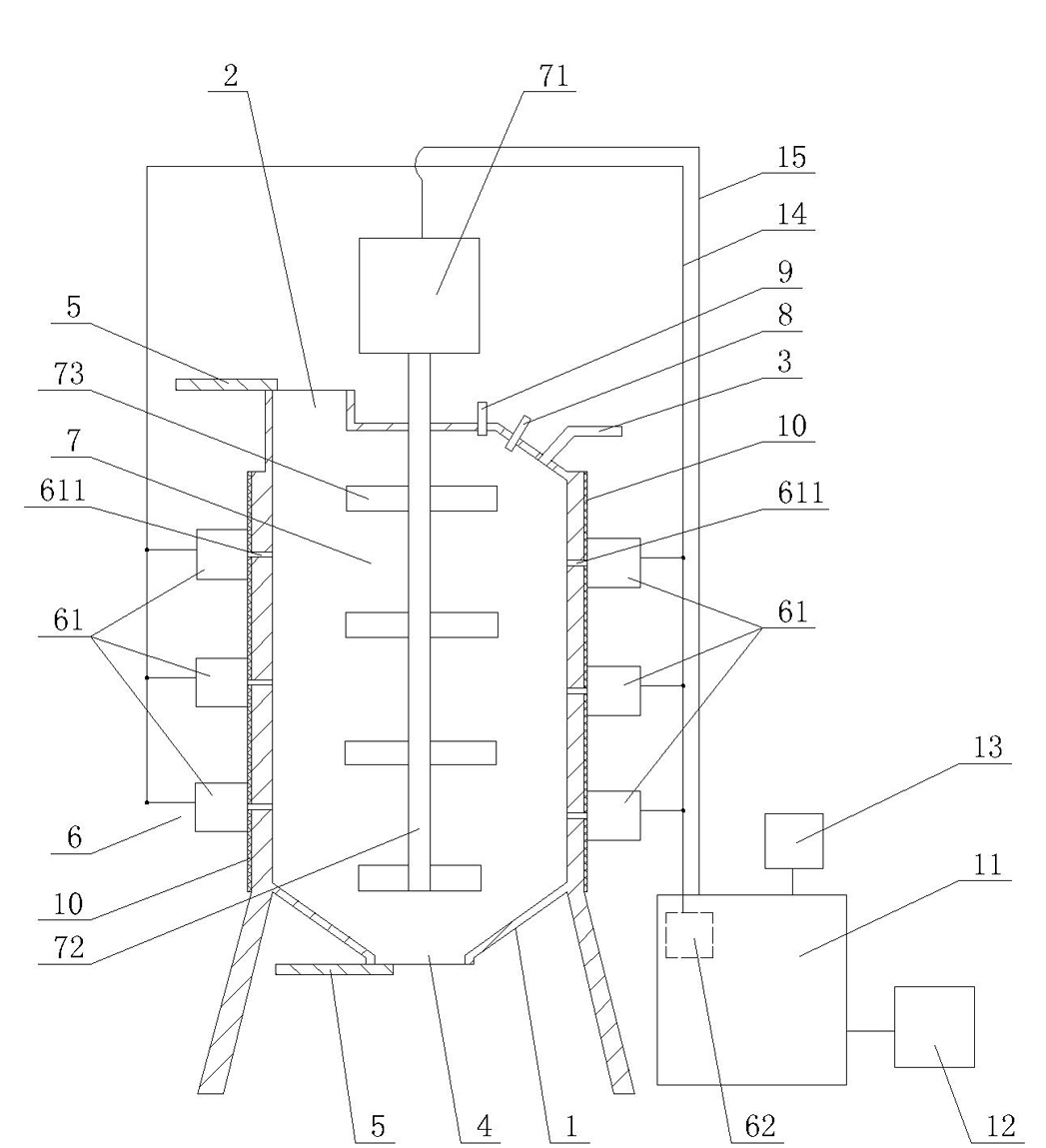

[0013] Such as figure 1 As shown, the plant material high-temperature preparation combustible gas device of the present invention includes a furnace body 1 and a material inlet 2 arranged on the upper part of the furnace body 1, a combustible gas outlet 3 and a waste material outlet 4 at the bottom, in order to make the heating effect of the present invention Good, high gas production rate, easy temperature control, safe and reliable, a microwave heating device 6 is connected to the furnace body 1 . This microwave heating device 6 includes several microwave tubes 61 asymmetrically arranged on the outer surface of the furnace body 1 and a microwave source 62 arranged outside the furnace body 1 and electrically connected to the microwave tubes 61, and the emission of each microwave tube 61 The head 611 communicates with the inside of the furnace body 1, and the microwave tube 61 located outside the furnace body 1 is connected to the microwave source 62 through the wire A14. Bec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com