Air distribution and slag cooling device and method for fluidized bed gasifier

A technology of fluidized bed gasifier and slag cooling device, which is applied in gasification process, granular/powder fuel gasification, chemical industry, etc., can solve the problem of large volume of slag cooler, back mixing, small heat transfer coefficient, etc. To achieve the effect of strengthening internal circulation and sorting of coarse and fine particles, improving carbon conversion rate and prolonging gasification time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

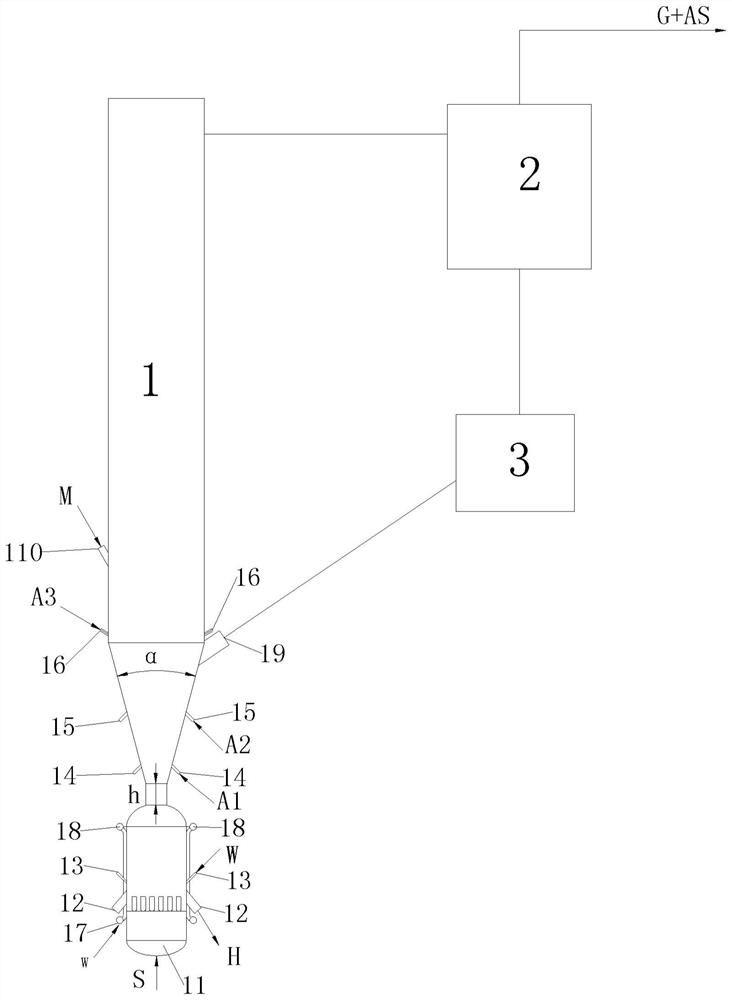

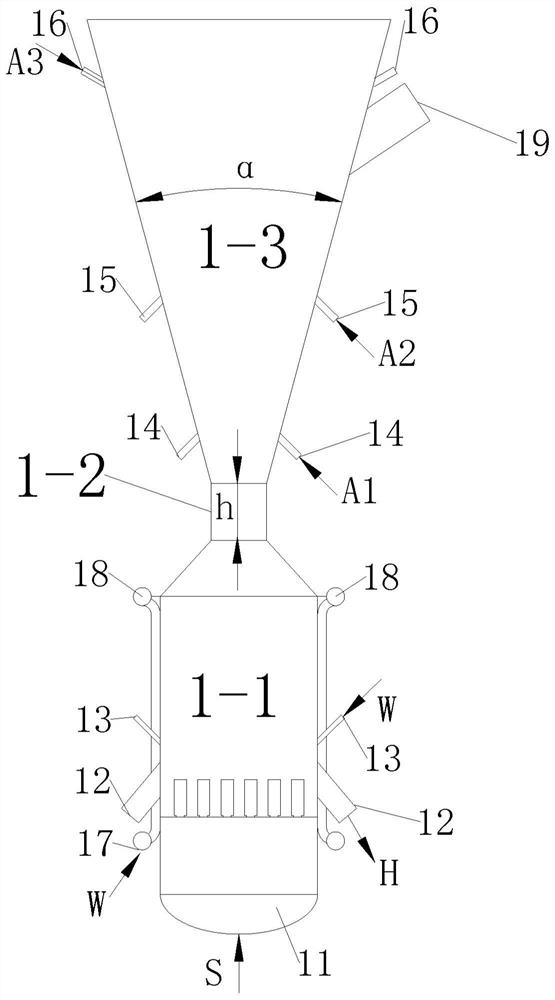

[0084] Embodiment 1 of the present invention provides an air distribution and slag cooling device and method for a fluidized bed gasifier. figure 1 Schematic diagram of the structure of the fluidized bed gasifier; figure 2 It is a schematic diagram of the structure of the air distribution and cooling slag device.

[0085] like figure 1 and figure 2 As shown, the fluidized bed gasifier includes a gasifier hearth 1 , a gas-solid separator 2 , and a feeder 3 . The feed port 110 of the gasifier is located above the feed port 19; the air distribution cooling slag device is a part of the fluidized bed gasification furnace, located at the bottom of the gasification furnace hearth 1, and consists of the air distribution cooling section 1-1, the throat 1- 2. Composed of air distribution section 1-3.

[0086] The air distribution cooling section 1-1 is a cylindrical structure composed of an air distribution assembly 11 at the bottom, a water wall, a slag discharge pipe 12 and a wa...

Embodiment 2

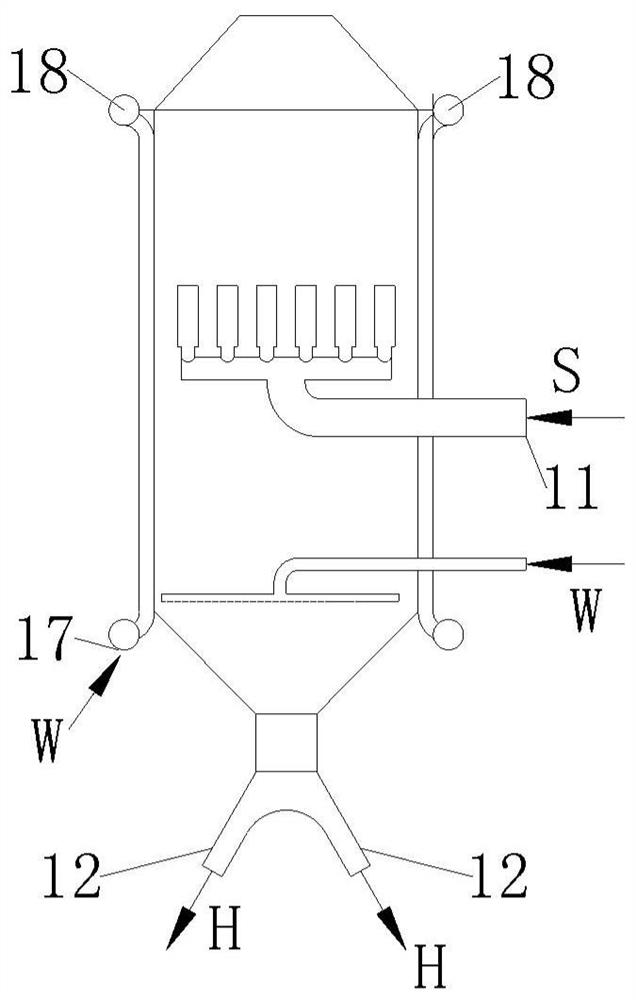

[0097] image 3 It is a schematic structural diagram of the air distribution cooling section for bottom slag discharge in Example 2 of the present invention.

[0098] like image 3 As shown, the structure of the air distributing and slag cooling device in Embodiment 2 of the present invention is the same as that in Embodiment 1, the difference is that: the slag discharge pipe 12 is located at the bottom of the air distribution and cooling section 1-1, and The upper part of the slag pipe 12 is provided with a water spray distributor. On the upper part of the water spray distributor is an air distribution assembly 11, which is composed of a wind cap and an air pipe, and the bottom slag can pass through the air distribution assembly 11. This structure makes the bottom slag from the throats 1-2 successively pass through the air distribution assembly 11 and the water spray distributor, and undergo countercurrent heat exchange with saturated steam S and water W respectively. This...

Embodiment 3

[0100] Figure 4 It is a schematic structural diagram of the air distribution and slag cooling device in Example 3 of the present invention.

[0101] like Figure 4 As shown, the structure of the air distributing and cooling slag device in Embodiment 3 of the present invention is the same as the structure of the air distributing and cooling slag device in Embodiment 2. It includes two sets of air distribution cooling sections 1-1. The air distribution and cooling section 1-1 of the air distribution and slag cooling device is provided with one standby and one active, which is beneficial to the long-term operation of the fluidized bed gasifier. In addition, a connection section is added between the throat 1-2 of the air distribution cooling slag device and the air distribution cooling section 1-1, which is beneficial to further improve the separation of coarse particles and fine particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com