Water heater outlet pipeline cold water recycling device

A water outlet pipeline, water heater technology, applied in the application, household heating, heating methods and other directions, can solve the problems of wasting water resources, difficult to popularize, etc., and achieve the effect of reducing movement resistance, simple structure, and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

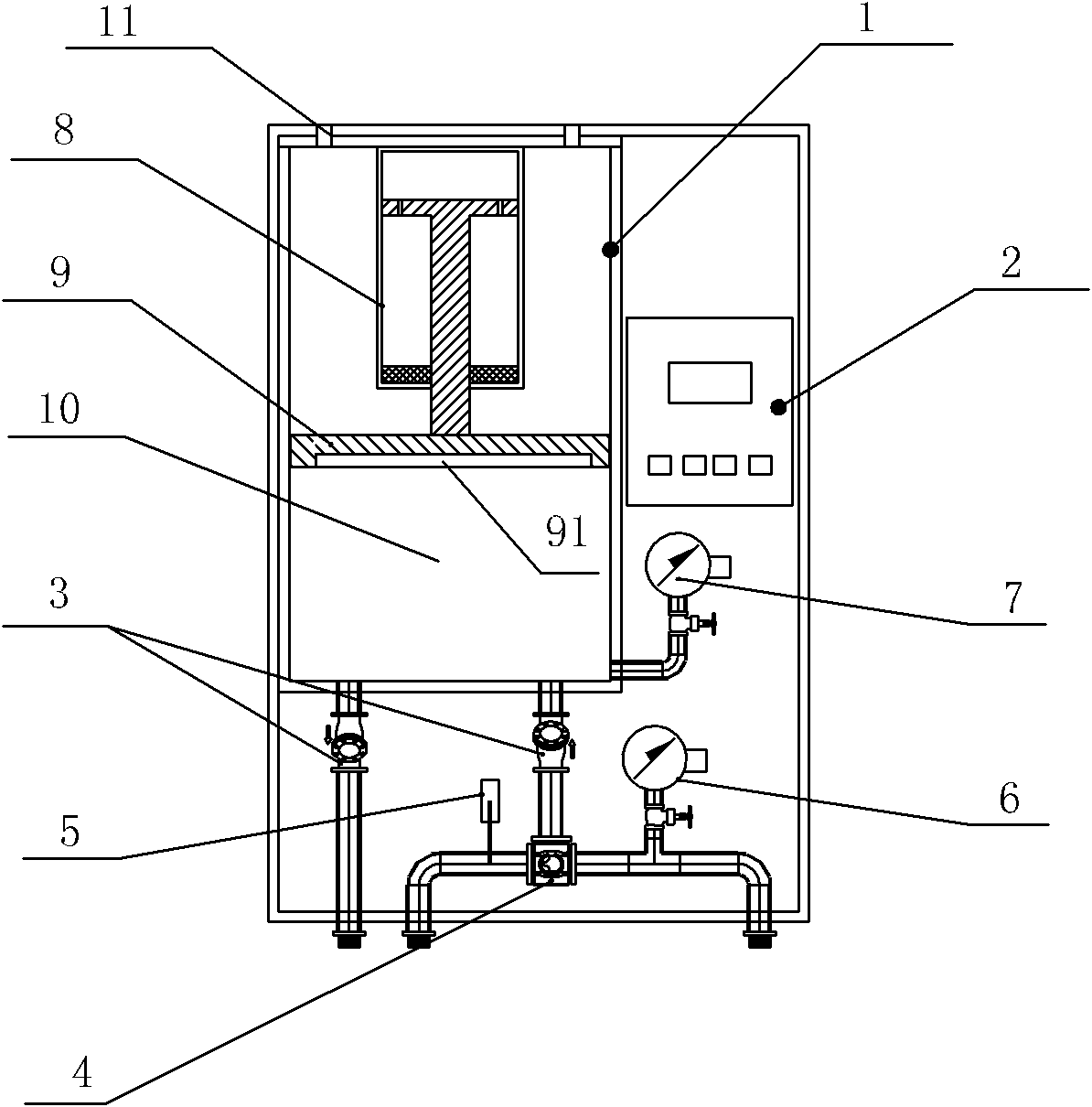

[0013] Embodiment one: if figure 1 As shown, the cold water recycling device of the water heater outlet pipeline includes a pressure water storage tank 1, a control module 2, a hot water inlet pipe 15, a hot water outlet pipe 14 and an electric three-way valve 4. The bottom of the pressure water storage tank 1 is provided with The cold water circuit inlet pipe 12 and the cold water circuit outlet pipe 13, the cold water circuit outlet pipe 13 is provided with a check valve, the inlet of the electric three-way valve 4 is connected with the hot water inlet pipe 15, the first outlet of the electric three-way valve 4 is connected with the cold water The loop water inlet pipe 12 is connected, the second outlet of the electric three-way valve 4 is connected with the hot water outlet pipe 14, the hot water inlet pipe 15 is provided with a temperature sensor 5, the hot water outlet pipe 14 is provided with a pressure sensor 6, and the pressure storage The top of the tank 1 is provided...

Embodiment 2

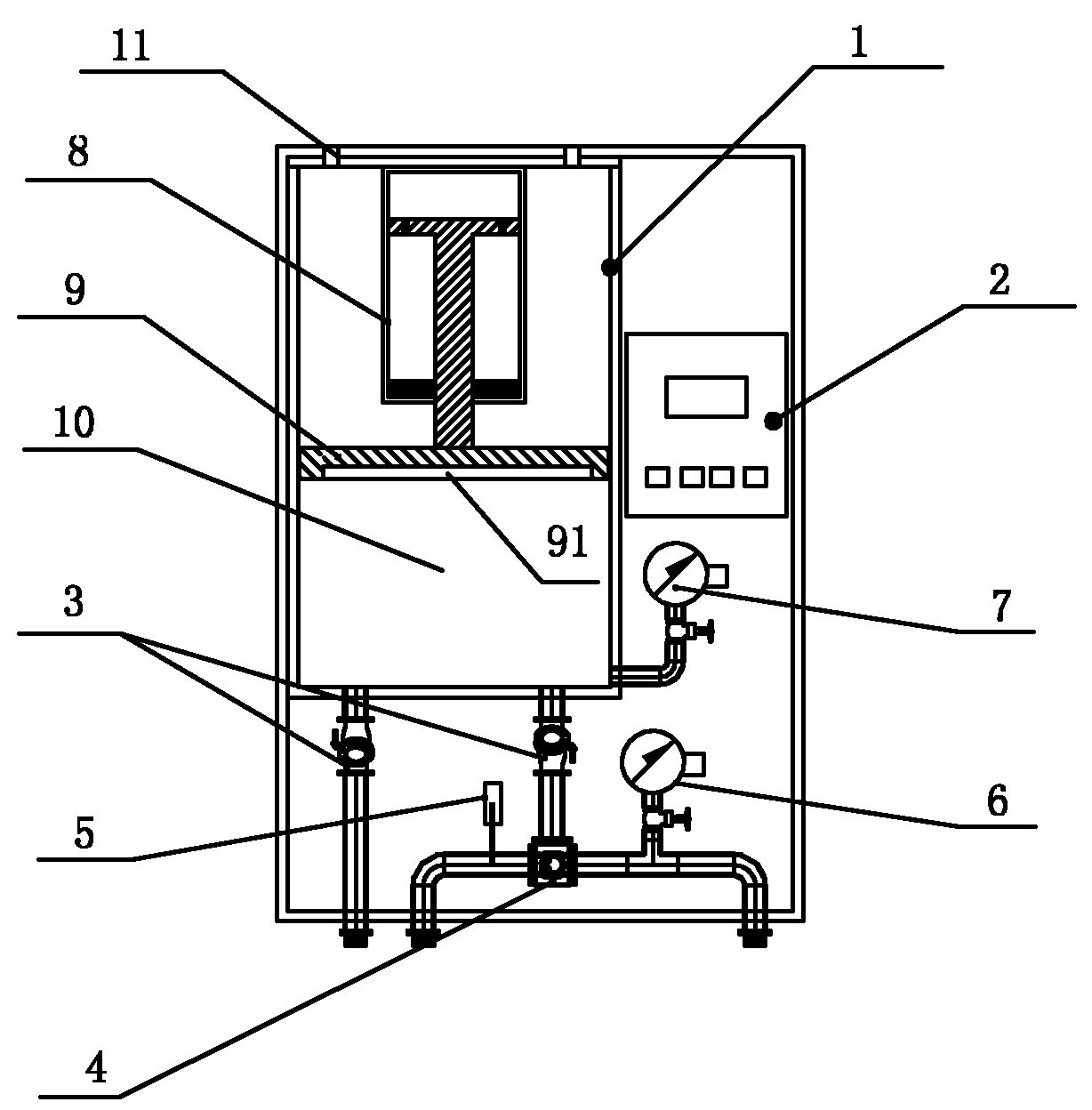

[0014] Embodiment 2: Other structures are the same as Embodiment 1, the difference is that the end surface of the piston 9 is provided with a cavity 91 .

[0015] In the above-mentioned embodiments, the gas spring 8 can be replaced by a mechanical spring or a hydraulic spring.

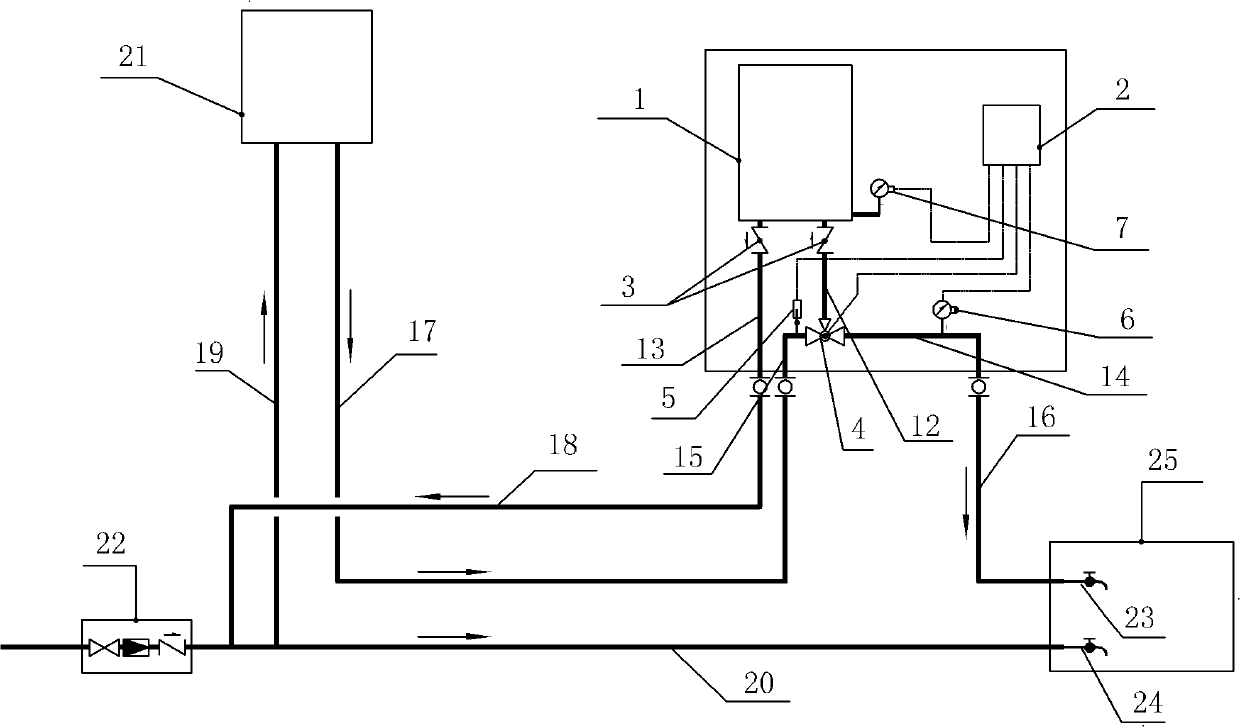

[0016] The working principle of the cold water reuse device in the outlet pipe of the water heater combined with the water heater is as follows: figure 2 As shown, the cold water circuit outlet pipe 13 is connected to one end of the water pipe 18, the other end of the water pipe 18 is connected to the cold water pipe 20, and one end of the water heater inlet pipe 19 is also connected to the cold water pipe 20, and the water inlet end of the cold water pipe 20 is provided with A control valve 22, the hot water inlet pipe 15 is connected with one end of the water heater outlet pipe 17, the hot water outlet pipe 14 is connected with the water pipe 16, the outlet end of the water pipe 16 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com