High-precision laser gyroscope inertia measurement system for POS

A laser gyro and inertial measurement technology, applied in the field of inertia, can solve the problems of lack of resistance to external harsh vibration environment, lack of high-precision laser gyro inertial measurement system for POS, poor stability and repeatability, etc., to improve temperature environment adaptability , Improve the anti-vibration interference ability, improve the effect of anti-magnetic interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

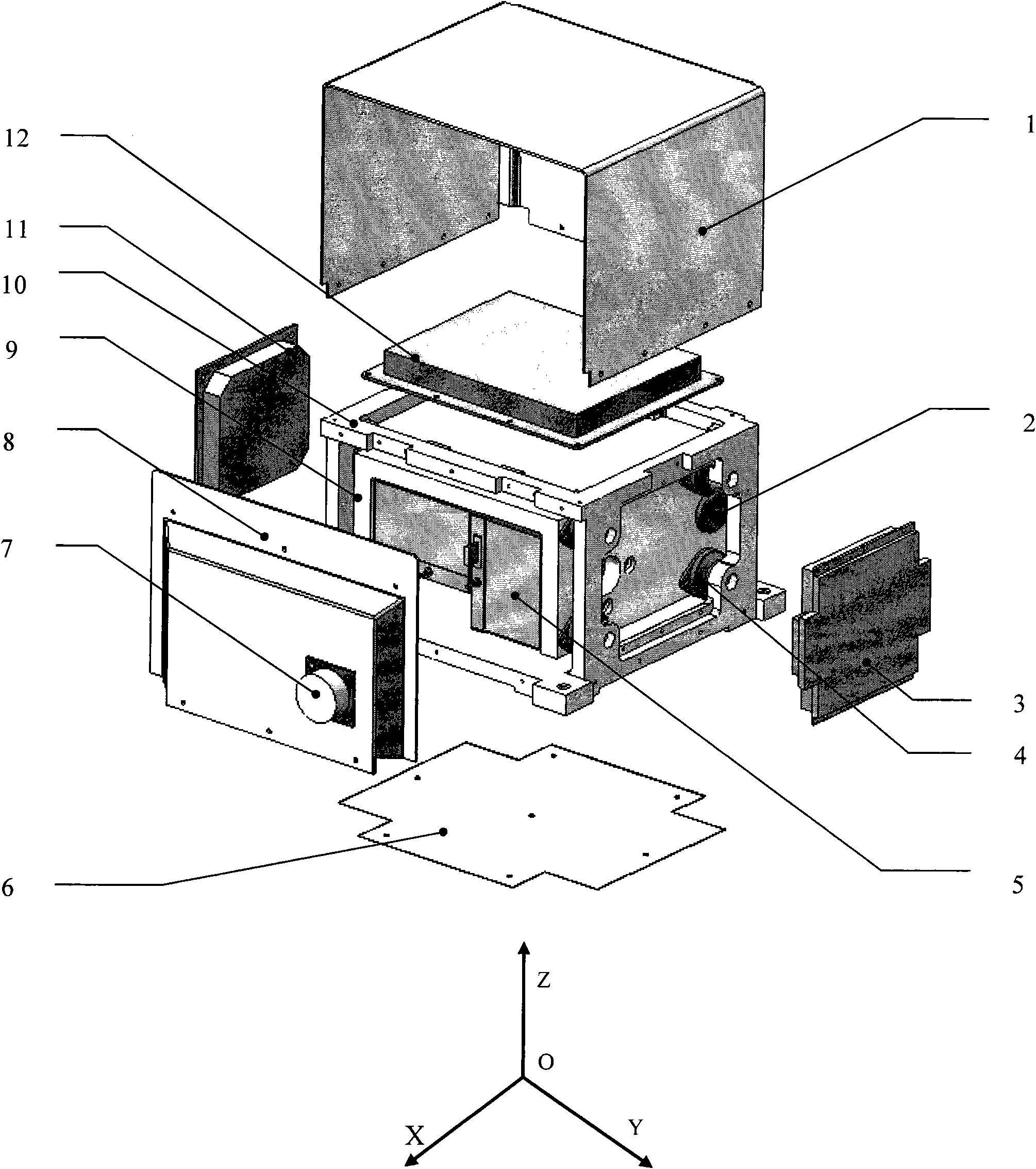

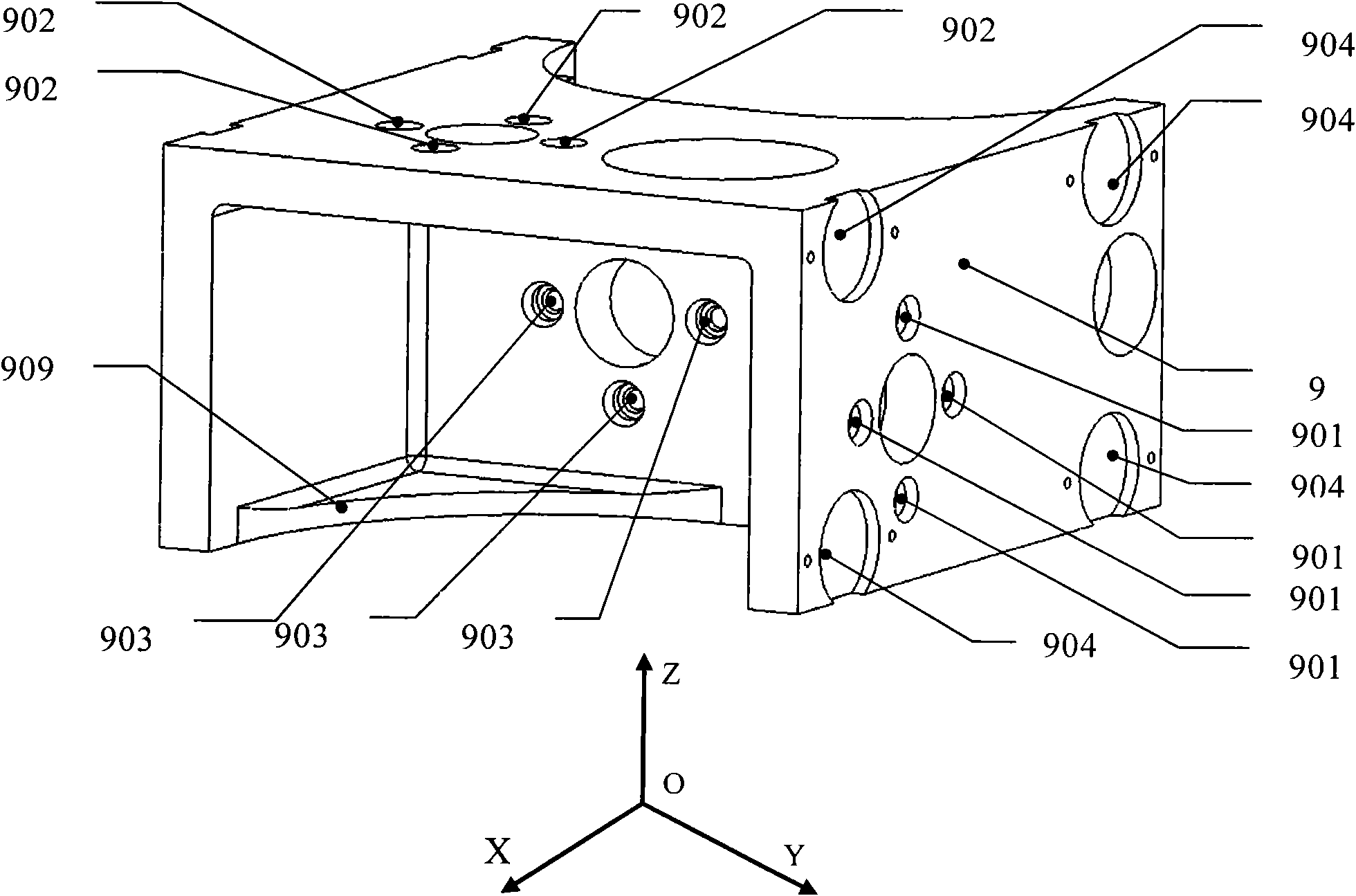

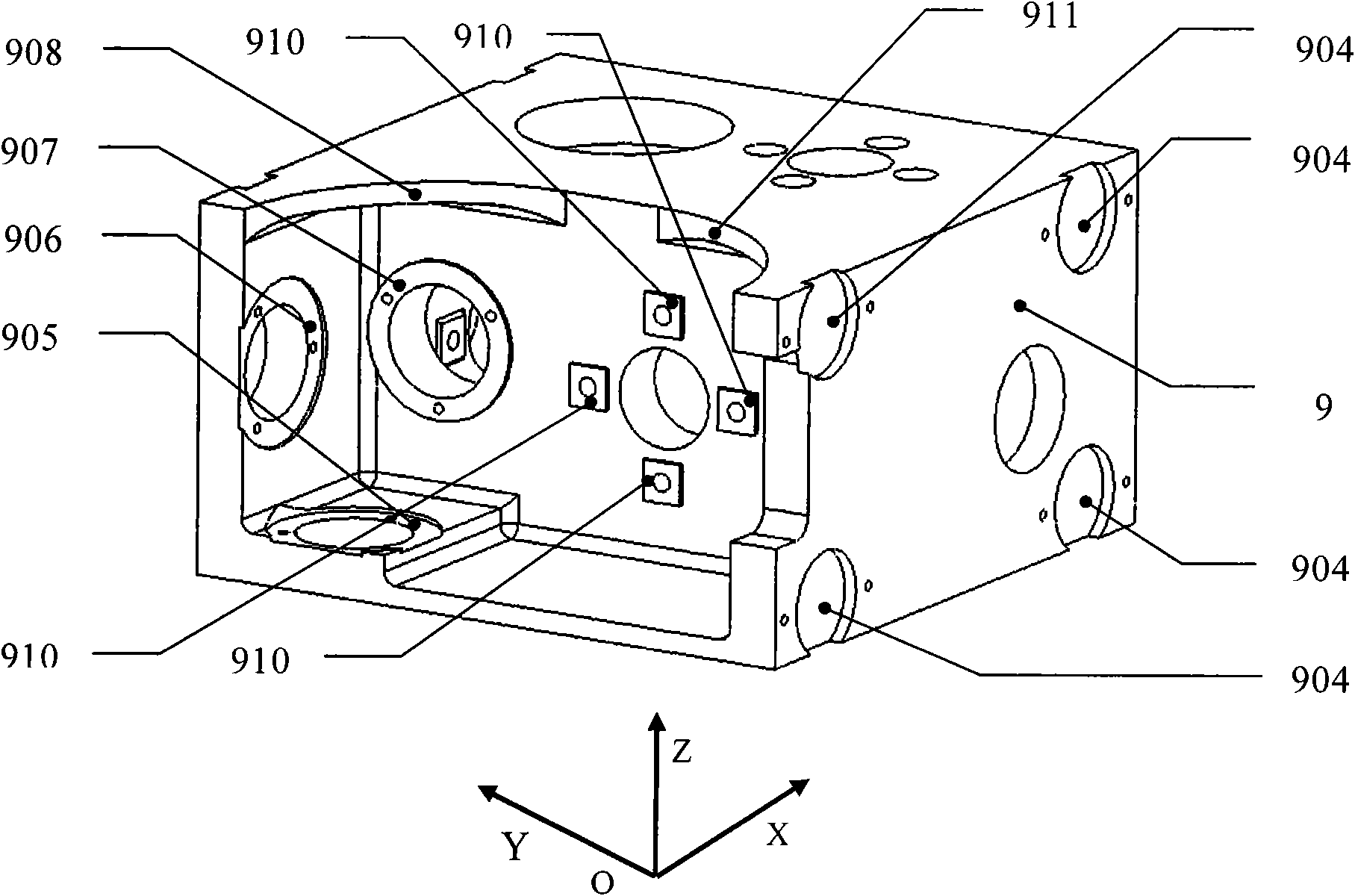

[0023] The specific implementation structure of technical solution of the present invention is as figure 1As shown, a high-precision POS laser gyro inertial measurement system includes three laser gyroscopes 5, three quartz accelerometers 2, an IMU structure 9, a support frame 10, a shock absorber 4, an I / F signal conditioning circuit 11, Acquisition and calculation computer 3 , secondary power supply 12 , casing 1 , front panel 8 , bottom panel 6 and plug connector 7 . Three laser gyroscopes 5 and three quartz accelerometers 2 are respectively orthogonally assembled on the IMU structure 9 , and the IMU structure 9 is assembled in the inner cavity of the supporting frame 10 through eight shock absorbers 4 on both sides. The secondary power supply 12 is installed on the upper frame of the support frame 10 by screws, and the I / F signal conditioning circuit 11 and the acquisition and resolution computer 3 are respectively installed in the grooves on the left and right side walls ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com