Measurement method for stress change of rocks during TBM tunneling

A measurement method and technology of surrounding rock stress, applied in the direction of measuring force, measuring devices, instruments, etc., can solve problems such as the reduction of the headroom of the cavern section, the impact on the secondary lining of the tunnel, and the difficulty of initial support, so as to speed up the construction progress and save Engineering quantity, to ensure the effect of overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

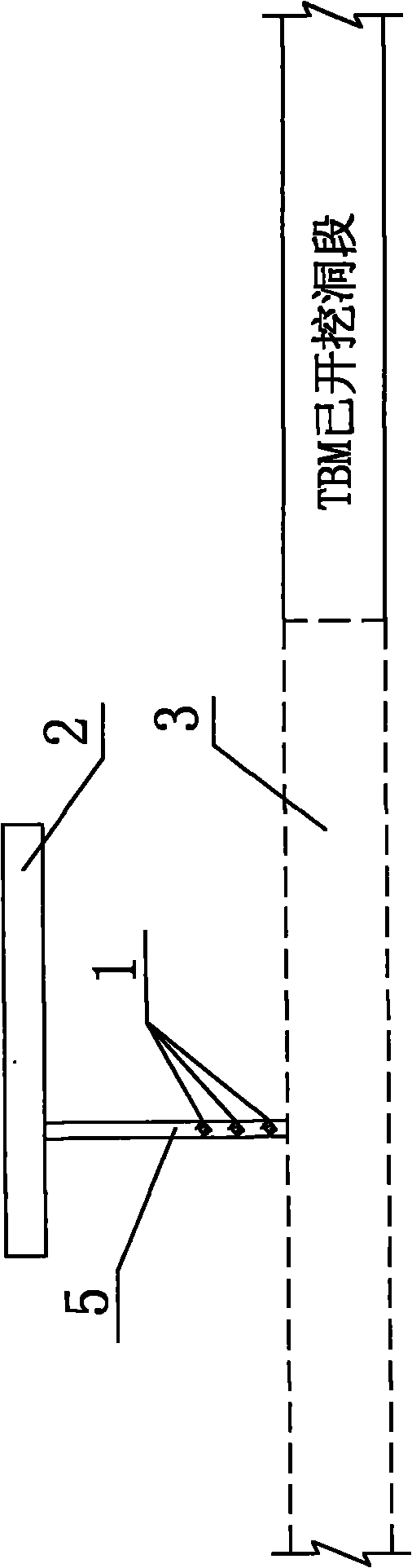

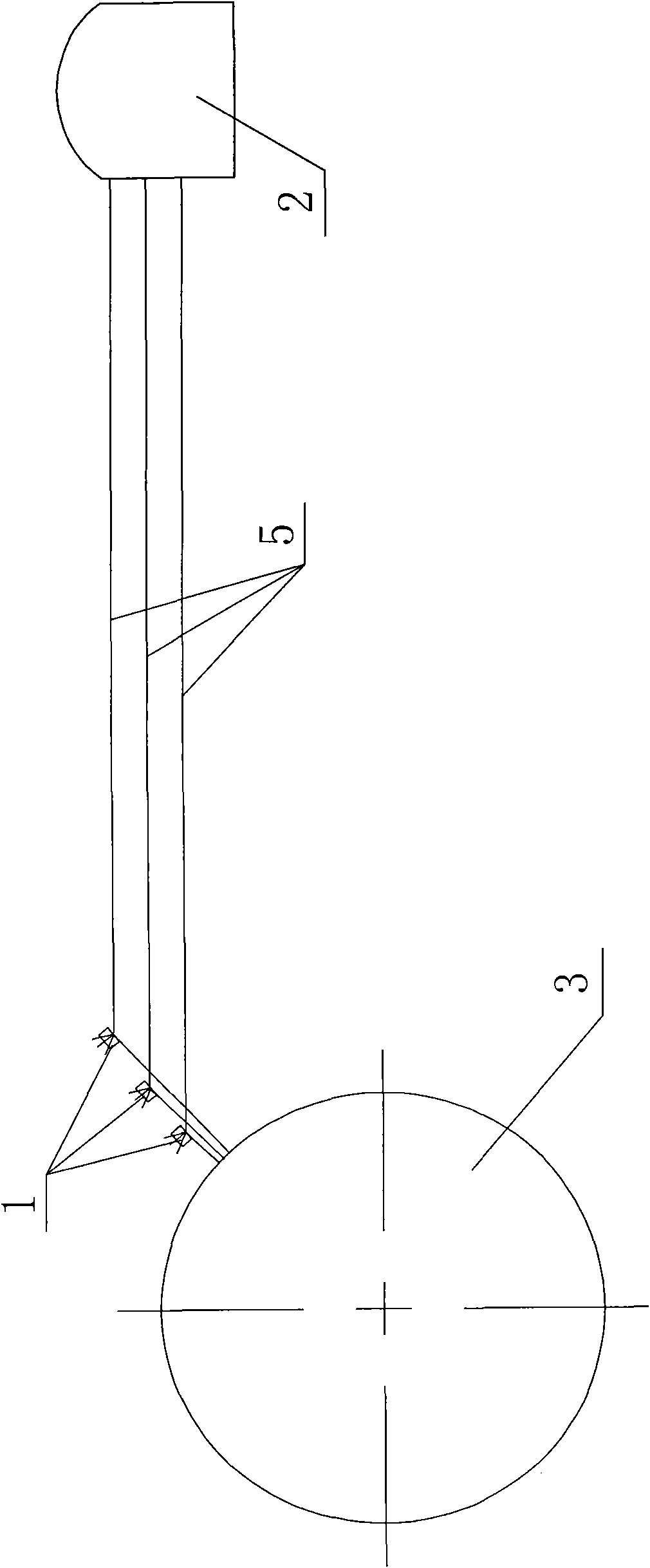

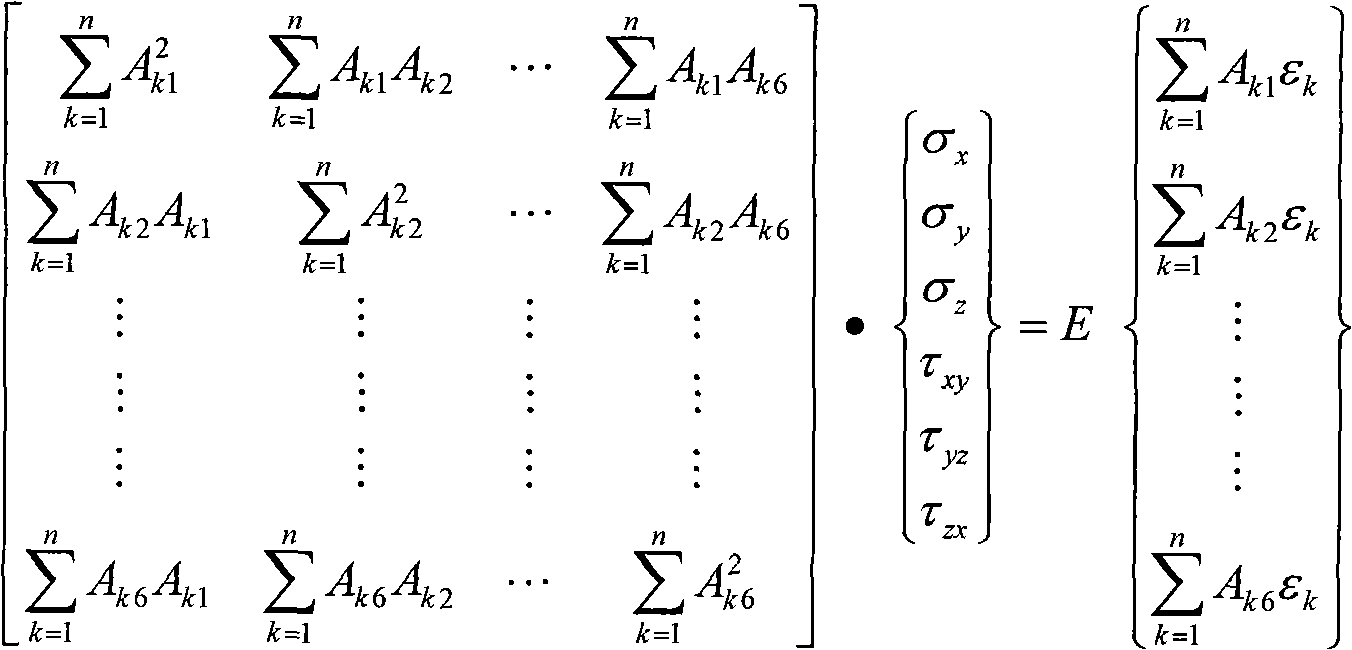

[0016] Such as figure 1 , figure 2 It can be seen that although the TBM excavation has little disturbance to the surrounding rock, it will still change the stress field of the original rock and affect the stability of the cavern. Unlike the drill and blast method, the TBM excavation has less damage to the surrounding rock and will not Destroy the pre-embedded hollow inclusion stress gauge, so the hollow inclusion stress gauge 1 can be buried at the design position in advance to monitor the stress change of the surrounding rock during TBM excavation. The steps are as follows:

[0017] a. Considering the comprehensive influence of the numerically calculated stress results, topography, rock mass strength, and faults, reasonably determine the embedding position and number of measuring points of the hollow inclusion stress gauge 1, and arrange the measuring points in the section 3 of the tunnel to be excavated by the TBM. And ensure the integrity of the surrounding rock mass. At ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com