Hydraulic drive injection based bottom sediment acoustic characteristic in-situ detecting system

A seabed sediment, in-situ detection technology, applied in measurement devices, scientific instruments, recording of measurement values, etc., can solve the problems of large sediment disturbance, reduced measurement accuracy, and reduced work efficiency, and reduced the cost of marine surveys. , The effect of improving the emission voltage response and broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

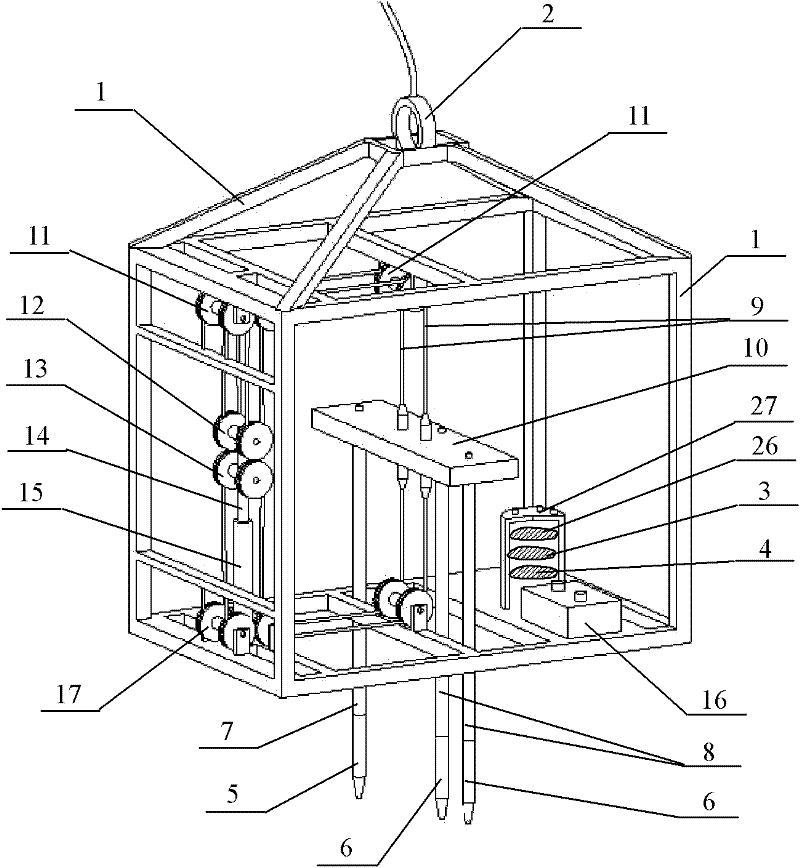

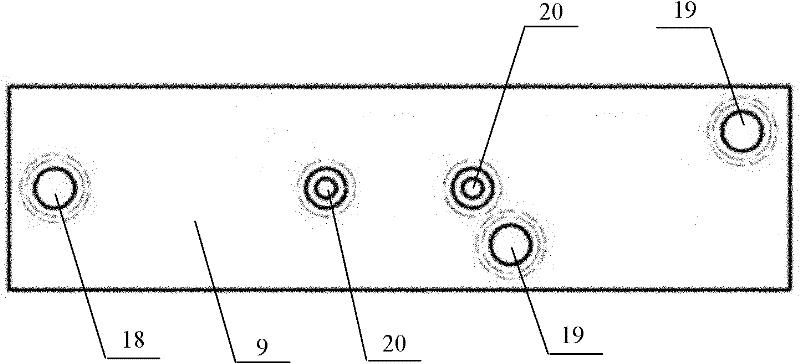

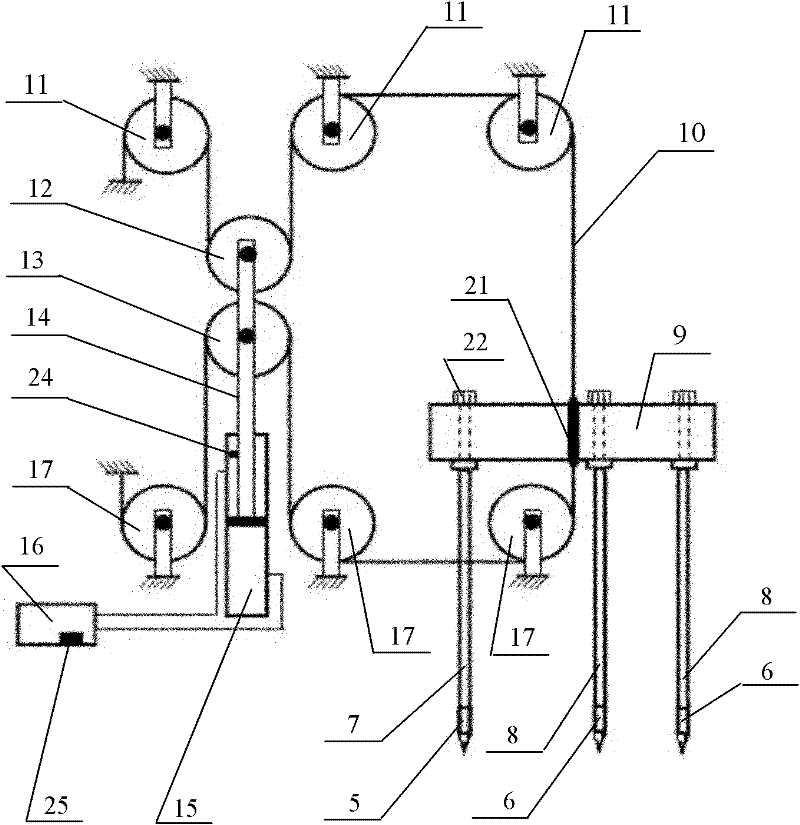

[0024] like figure 1 , 3 As shown, the present invention includes a frame 1 with a hoisting ring 2, a transmitting probe rod 7 with a transmitting transducer 5 and a receiving probe rod 8 with a receiving transducer 6, and fixed on the frame 1. The sealed chamber 27 containing the automatic control unit 3 and the acoustic wave emission collection unit 4, and the transducer penetration device, characterized in that the transducer penetration device is the hydraulic penetration drive device of the pulley combination mechanism, the The transducer penetration device includes a hydraulic pump 16 fixed on the bottom of the frame 1 , a hydraulic rod 14 in a hydraulic cylinder 15 driven by the hydraulic pump 16 , a lower moving pulley 13 and an upper moving pulley 12 fixed on the upper end of the hydraulic rod 14 , and The three upper fixed pulleys 11 fixed on the upper part of the frame 1, the three lower fixed pulleys 17 fixed on the lower part of the frame 1, and the movable press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com