Annular break blocking filter rod

A nozzle rod and ring-shaped technology, applied in the field of filter fiber nozzle rod, can solve the problem of low interception efficiency, achieve the effects of reducing bad smell, improving deposition efficiency and enhancing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

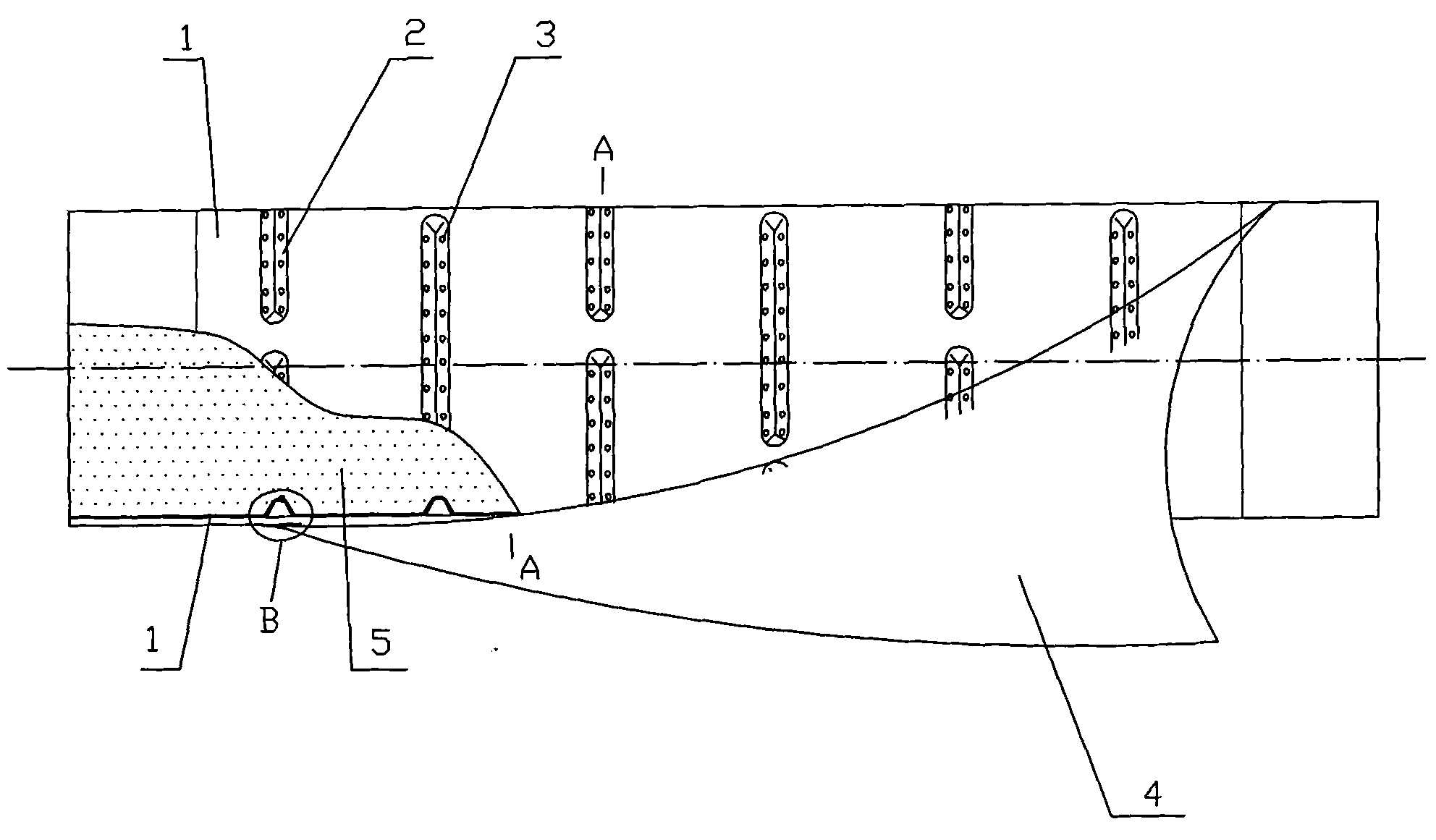

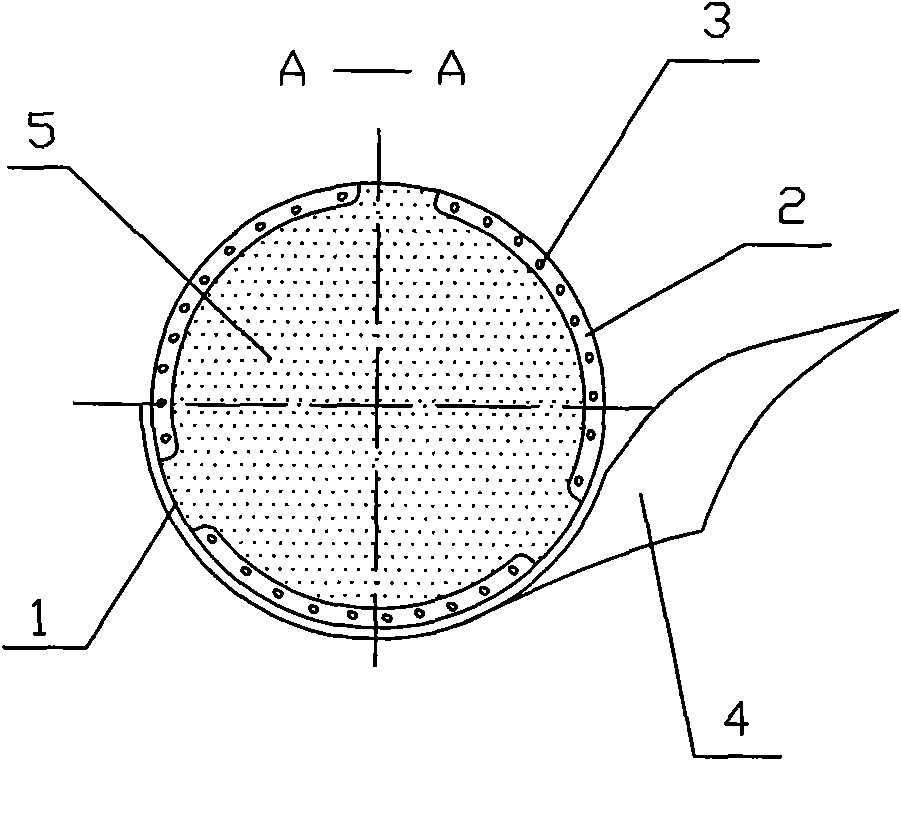

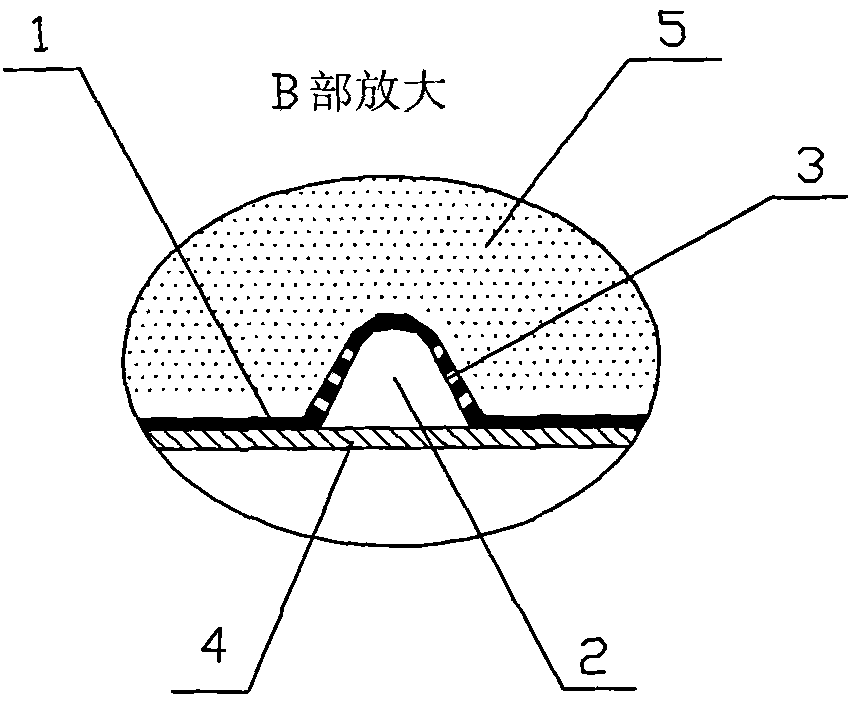

[0024] Such as figure 1 , figure 2 As shown, the present invention provides a ring-shaped cut-off nozzle rod, which is composed of tow mandrel 5 and outer wrapping forming paper 4, and a layer of wrapping tow is arranged between tow mandrel 5 and forming paper 4. The inner layer paper 1 of the mandrel, the inner layer paper 1 is pre-set with 7 circuit breaking rings surrounding the tow mandrel, each circuit breaking ring is composed of three transverse grooves 2 arranged along the circumference of the tow mandrel, each A group of small drainage holes 3 are respectively provided on both sides of each transverse groove, and the number of small drainage holes is 1-500. In the range of 0.01-1.0MM. The longitudinal cross-sectional shape of the transverse groove is circular.

[0025] Transverse grooves 2 and drainage holes 3 such as image 3 As shown, the transverse groove 2 compresses the tow mandrel 5 toward the center to increase the center density, forcing part of the smoke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com