Method for quick false tooth formation and false tooth

A fast technology for dentures, applied in the direction of dentures, etc., can solve the problems of expensive production cost, consumption, user discomfort, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

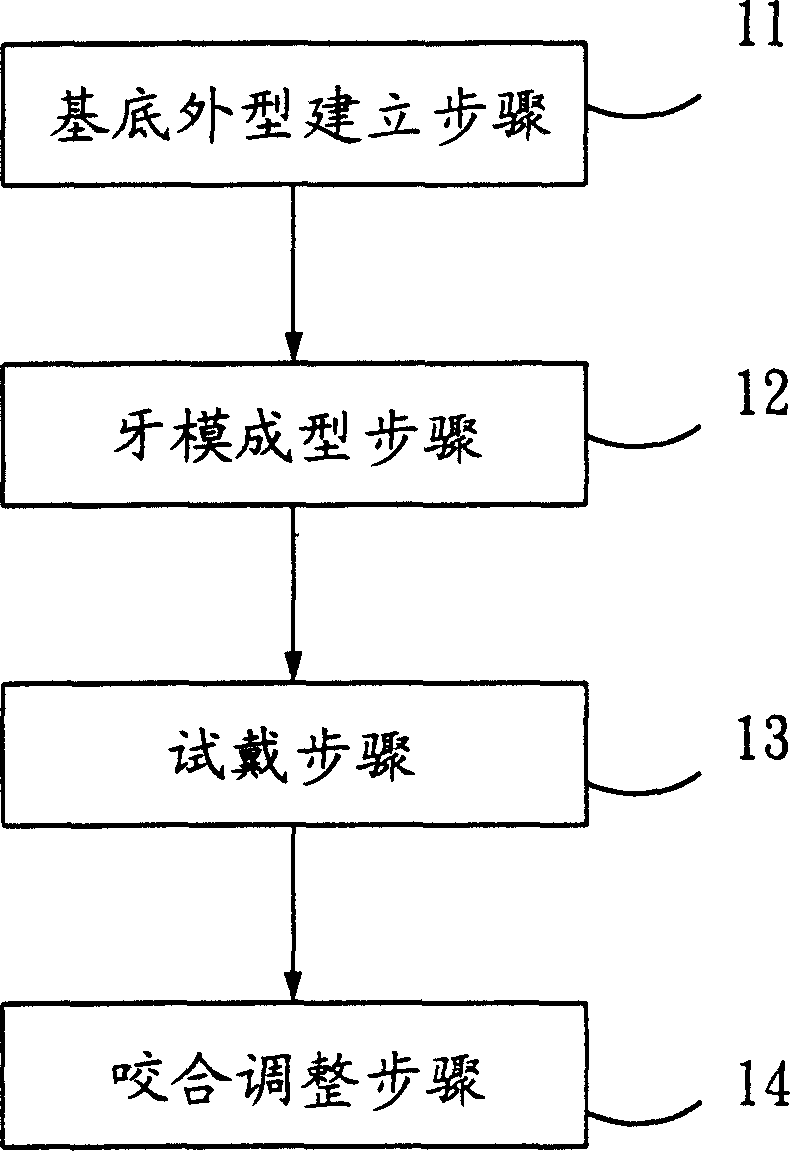

[0056] refer to Figure 4 , 5 , 6. A first preferred embodiment of the method for rapidly forming dentures of the present invention includes a base mold forming step 31 , a try-in step 32 and a trimming step 33 in sequence.

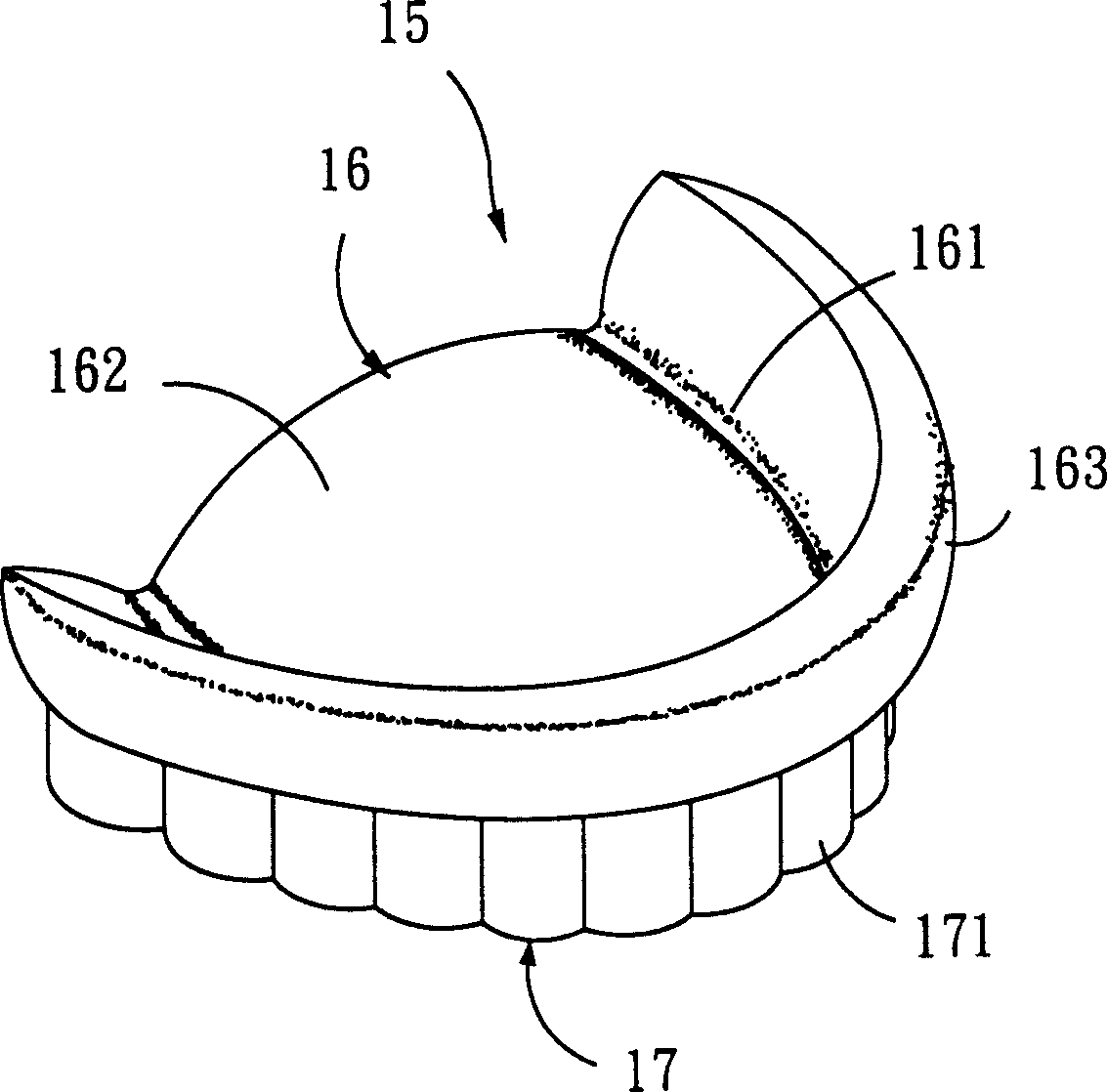

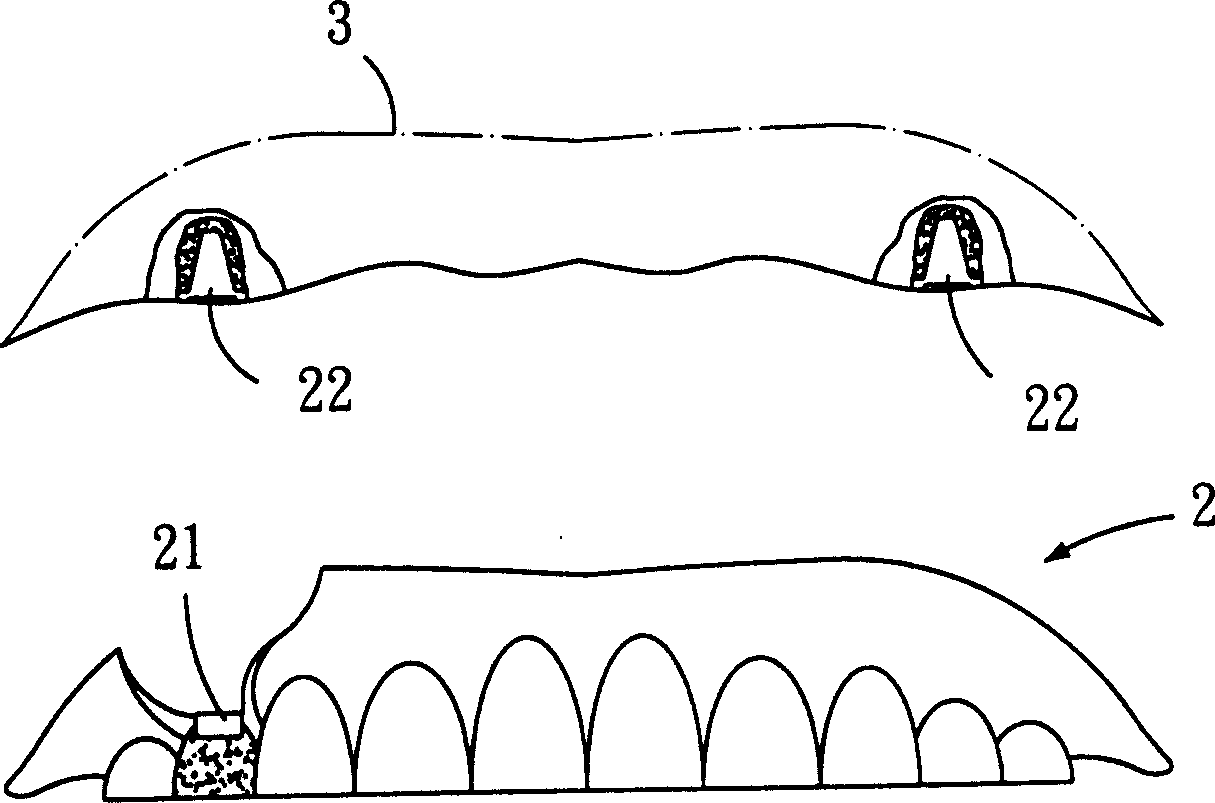

[0057] The basic mold forming step 31 is to pre-fabricate a plurality of basic molds 4 that can cover the structural differences of the oral cavity 6 of most users and have different single tooth 421 shapes and sizes according to the difference range of the human oral cavity structure. And each base model 4 all comprises a base 41 that can be attached to the upper jaw 61 and the gum 63 of the user's oral cavity 6, and a dentition that protrudes downward from the bottom of the base 41 and has a plurality of parallel single teeth 421 42. The base 41 and the teeth row 42 are integrally formed. And the tooth row 42 is integrally formed, and the outer surface of the tooth row 42 depicts a plurality of single teeth 421 side by side, so the tooth row 42 does ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com