Chelate resin tower

A chelating resin tower and chelating resin technology, applied in ion exchange, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of no backwash filter device, increased maintenance time, and increased cost of rubber lining, etc. Achieve the effect of ensuring safe operation, reducing maintenance time, reducing manufacturing costs and rubber lining costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

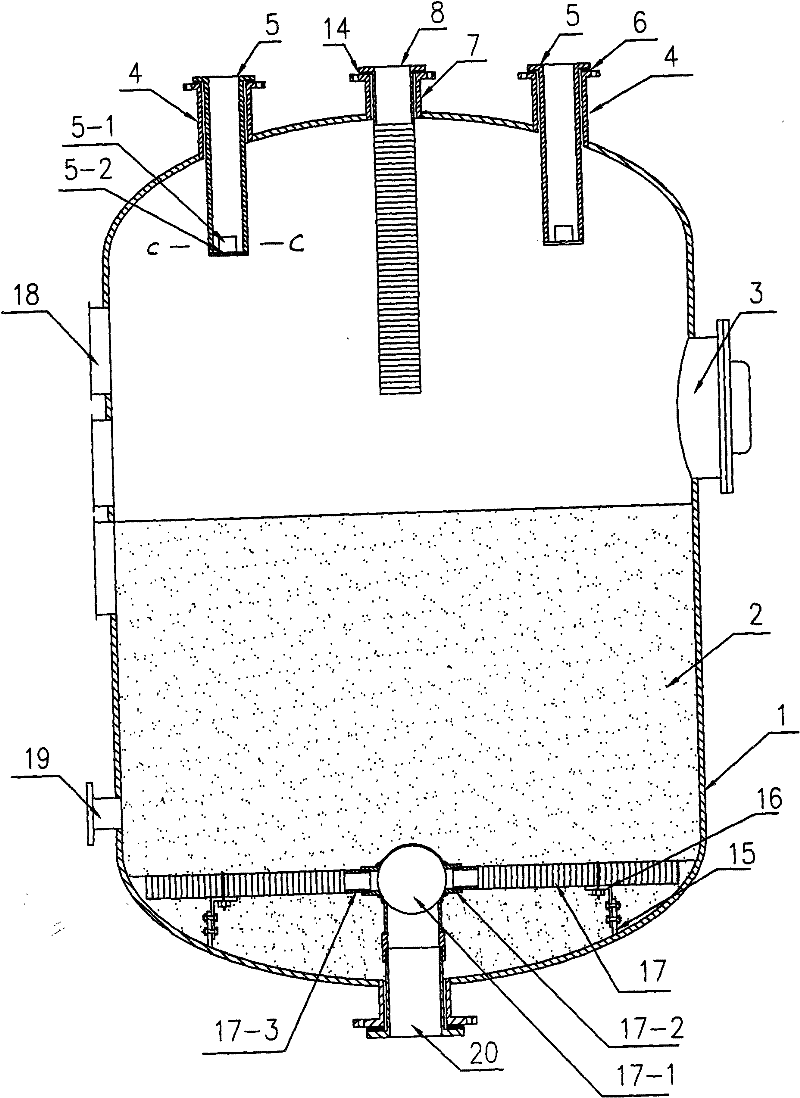

[0038] Such as figure 1 As shown, the technical solution adopted by the present invention includes a cylinder body and a tower body 1 directly welded to the upper and lower ends of the cylinder body. The tower body 1 is provided with a manhole 3, a sight glass 18 and a resin discharge hole 19. Chelating resin is housed in body 1 and forms chelating resin layer 2;

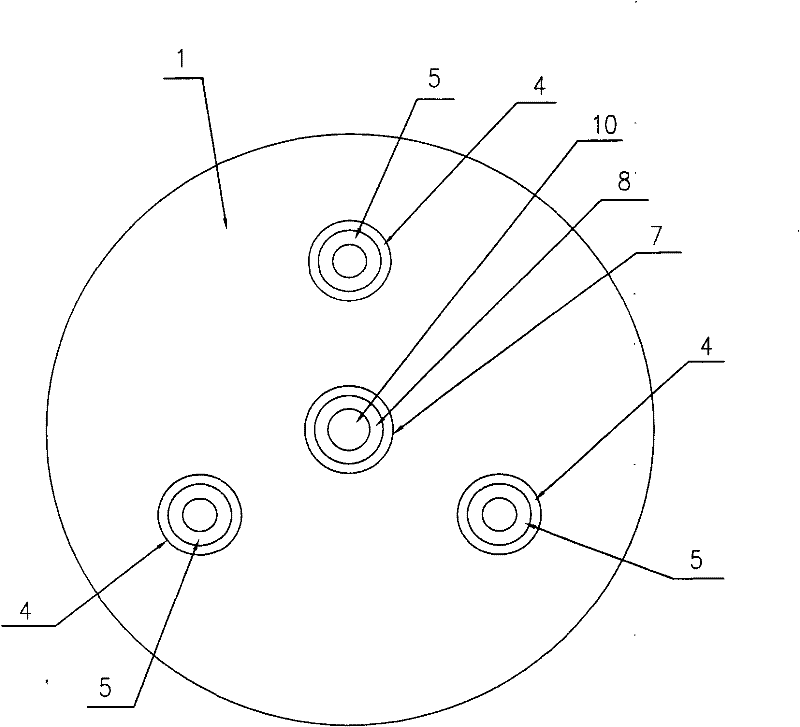

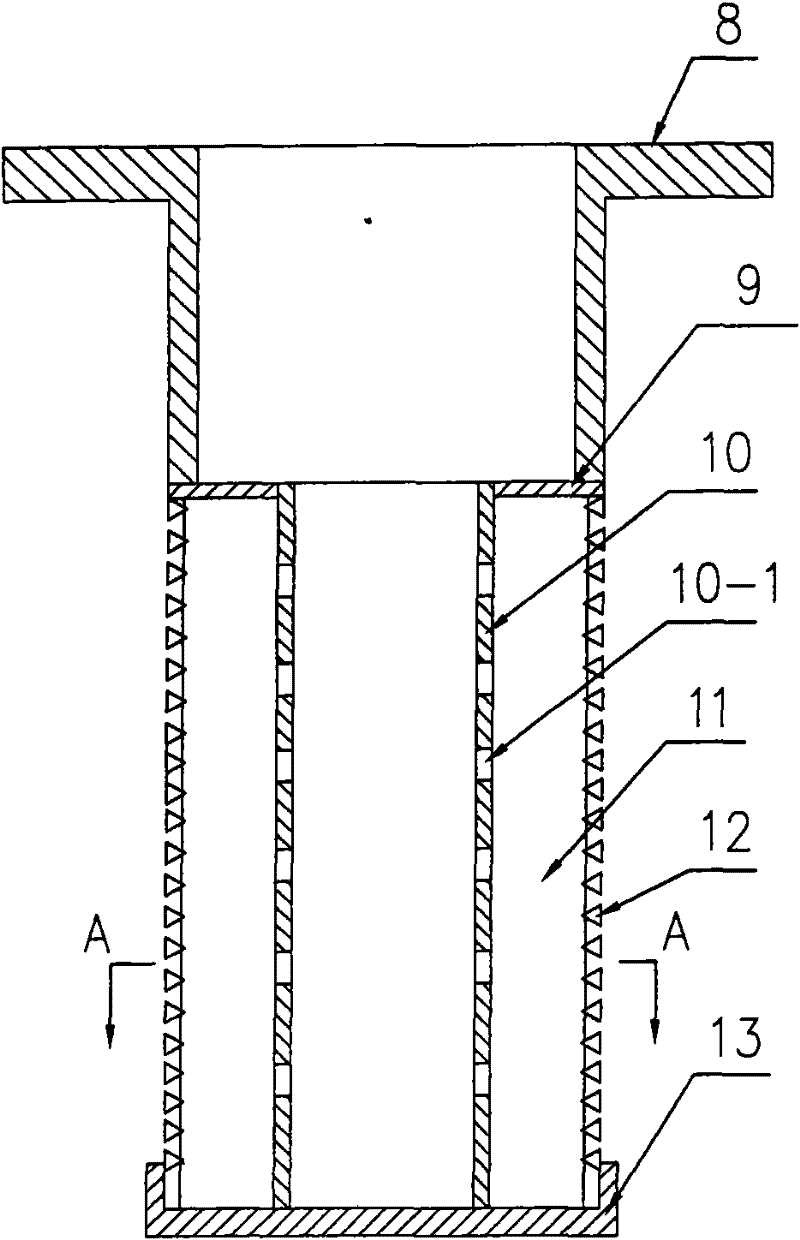

[0039] In order to make the distribution of salt water more even when entering the tower body 1, as figure 1 , figure 2 and Figure 8 As shown, three brine inlet connecting pipes 4 with flanges are welded on the top of the tower body 1, and nozzles are installed in the three brine inlet connecting pipes 4 and are provided with flanges and directly extend into the tower body 1 The inner water inlet pipe 5, the three water inlet pipes 5 are distributed at 120 degrees on the top of the tower, and the water inlet sealing rubber pad for sealing is installed between the flange of the water inlet pipe 5 and the flange ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com