Isometric replaceable four-cylinder line-lock two-plate type mould clamping mechanism

A mold clamping mechanism and equal volume technology, which is applied in the field of two-plate mold clamping mechanism, can solve the problems of large processing volume of internal circulation oil cylinder, high processing precision requirements, and large size of mold clamping mechanism, so as to improve design flexibility, strength and Guaranteed rigidity, simple processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

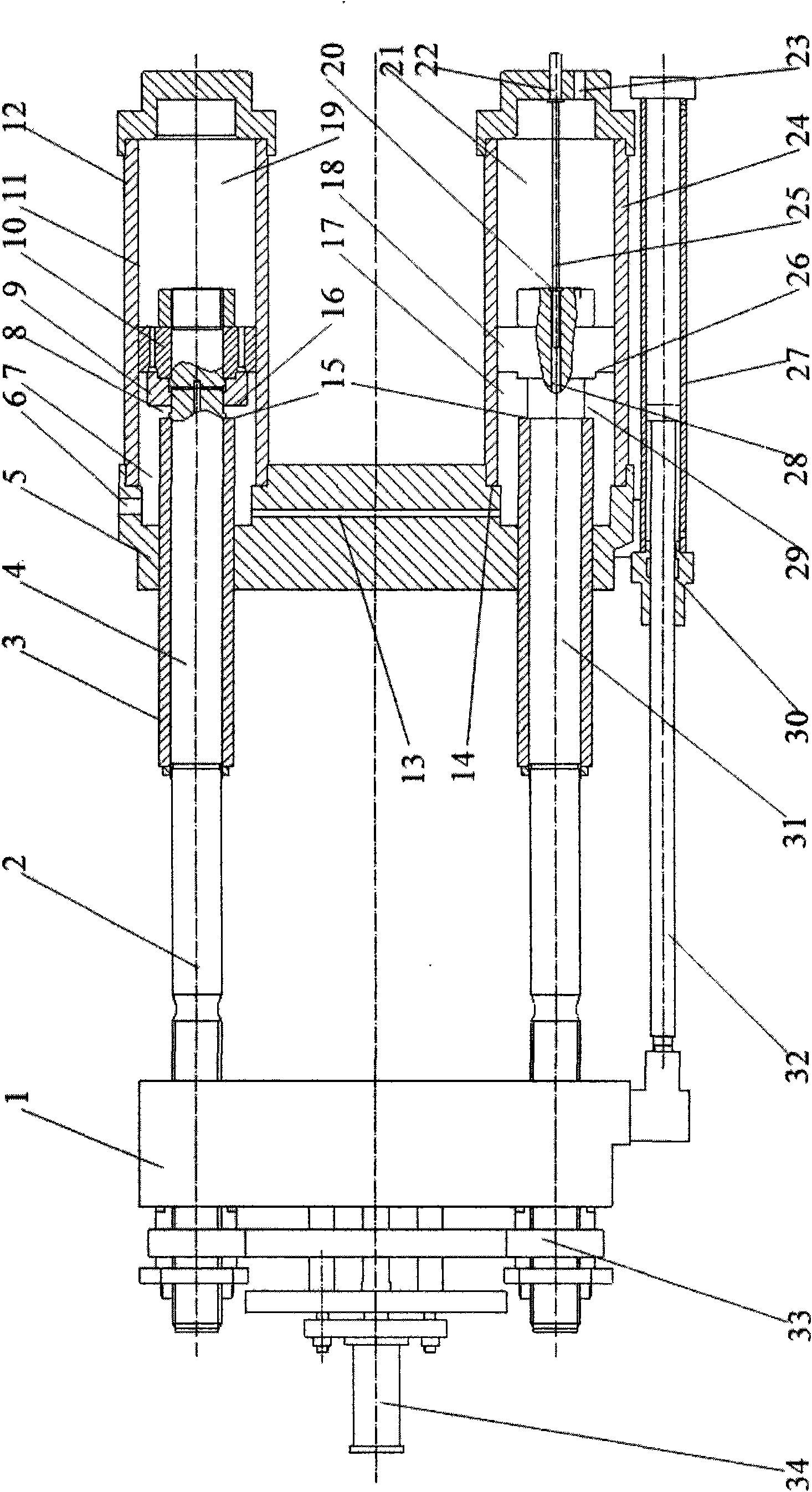

[0020] Such as figure 1 As shown, an equal-volume replacement four-cylinder direct-lock two-plate mold clamping mechanism of the present invention mainly consists of a movable template 1, a fixed template 5, a tie rod 2, a mold adjusting device 33, an ejector device 34, a mold transfer cylinder 30, an internal circulation Clamping cylinder 12, common clamping cylinder 14 and displacement sensor 22 form. The mold-moving cylinder piston rod 32 is fixed to the movable template 1, and the mold-moving cylinder body 27 is fixed on the periphery of the fixed template 5; the inner circulation mold-clamping cylinder 12 is composed of a piston rod-4 integrated with the pull rod 2, a sleeve 3, and a valve seat 9. Piston one 10 and cylinder body one 11. The sleeve 3 is set on the piston rod one 4. The distance between the end face 15 of the sleeve and the end face 16 of the slide valve is 8; Rod 2 31, sleeve 3, piston 2 18 and cylinder 2 24 are composed. The oil return chamber 21 of the ...

Embodiment 2

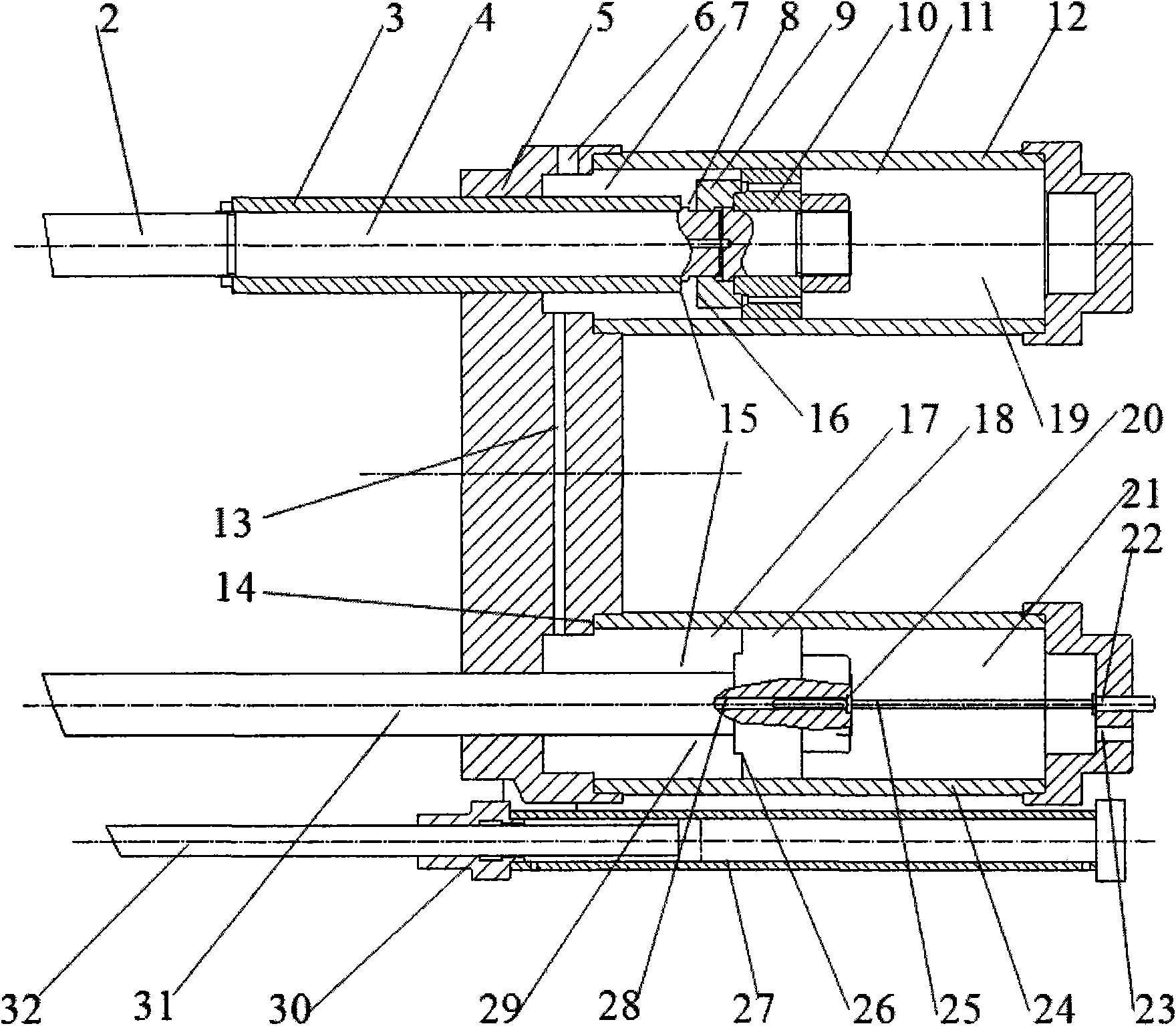

[0024] see figure 2, the structure, working principle and effect of this embodiment and embodiment 1 are basically the same. The difference is that the sleeve 3 is only provided on the two diagonal piston rods 1-4. The sleeve 3 can also be arranged on any one or three of the first piston rod 4 of the two internal circulation mold clamping cylinders 12 and the second piston rod 31 of the two ordinary mold clamping cylinders 14 . The two sleeves 3 can ensure that the volume change of the oil return cavity 19 of the inner circulation mold locking cylinder is equal to the volume change of the mold locking cavity 7 of the inner circulation mold locking cylinder and the volume change of the mold locking chamber 17 of the ordinary mold locking cylinder during the mold shifting process. Sum.

Embodiment 3

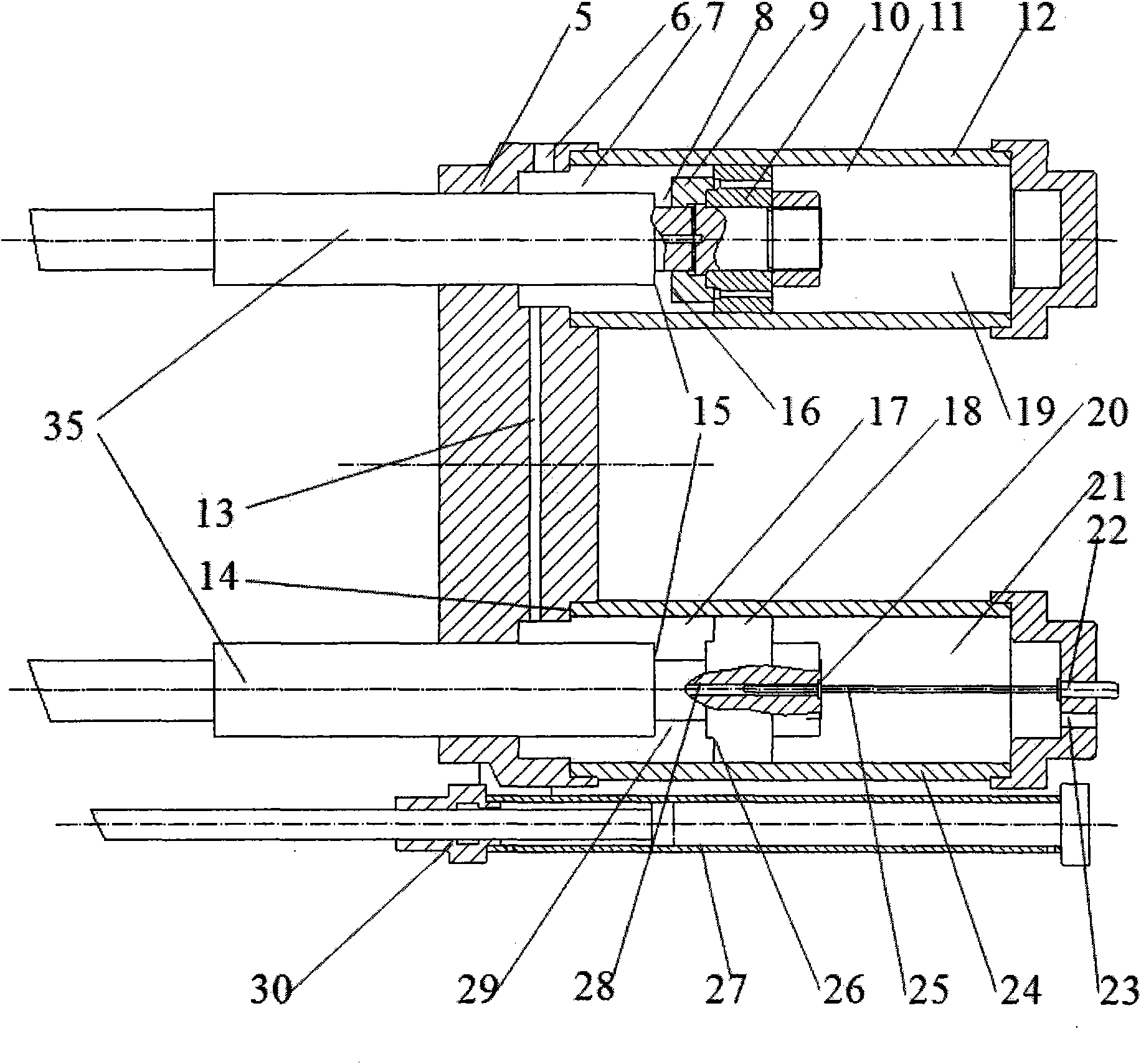

[0026] see image 3 , the structure, working principle and effect of this embodiment and embodiment 1 are basically the same. The difference is that the sleeve 3, the first piston rod 4 and the second piston rod 31 are integrated, that is, the place where the sleeve 3 is installed on the first piston rod 4 and the second piston rod 31 is thickened. The thickened part 35 of the piston rod can ensure that during the mold shifting process, the volume change of the oil return chamber 19 of the internal circulation mold clamping cylinder is equal to the volume change of the cavity 7 of the internal circulation mold clamping cylinder and the volume change of the cavity 17 of the ordinary mold clamping cylinder. and.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com