Method for mounting medium-deep buried water stop of tunnel archwall lining concrete toroidal construction joint

A technology of waterstop and concrete, which is applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve problems such as the insecure fixation of buried waterstop, and achieve the effects of improving construction quality, positioning accuracy, and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

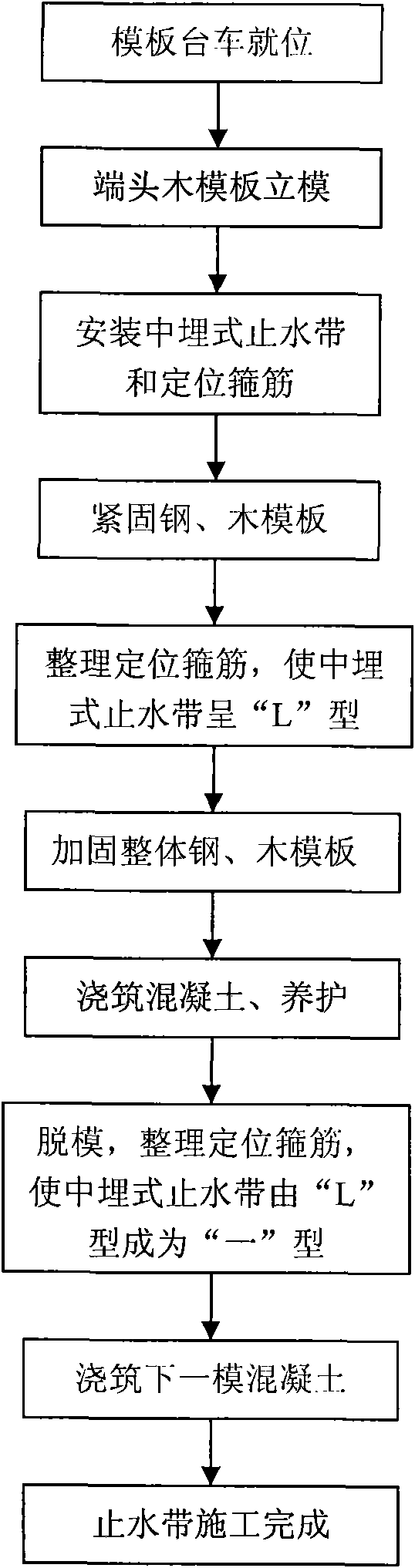

Method used

Image

Examples

Embodiment Construction

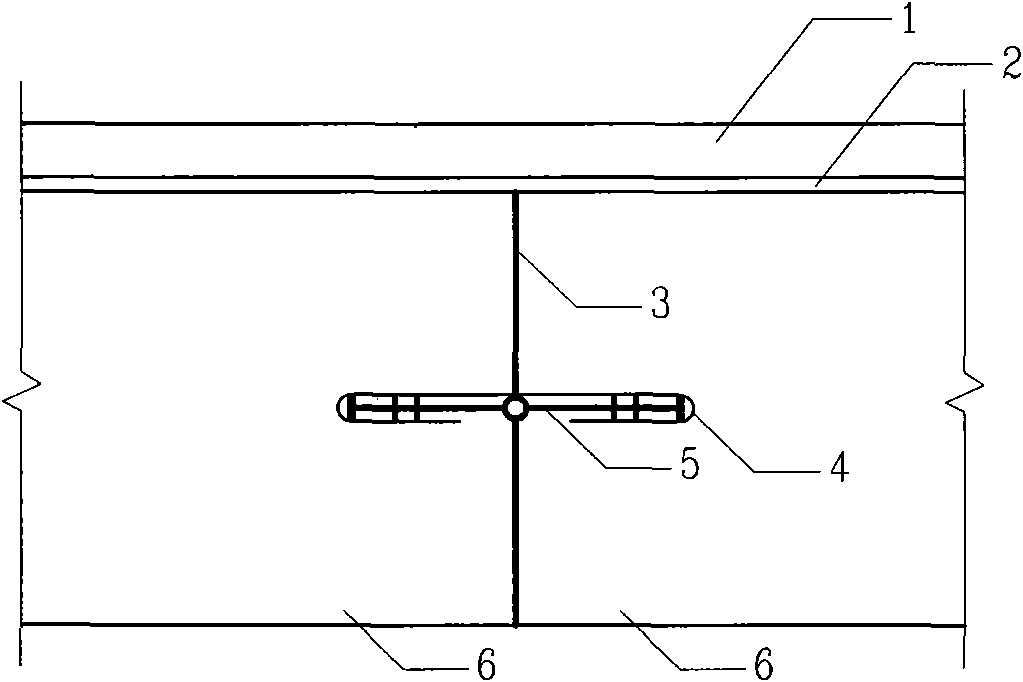

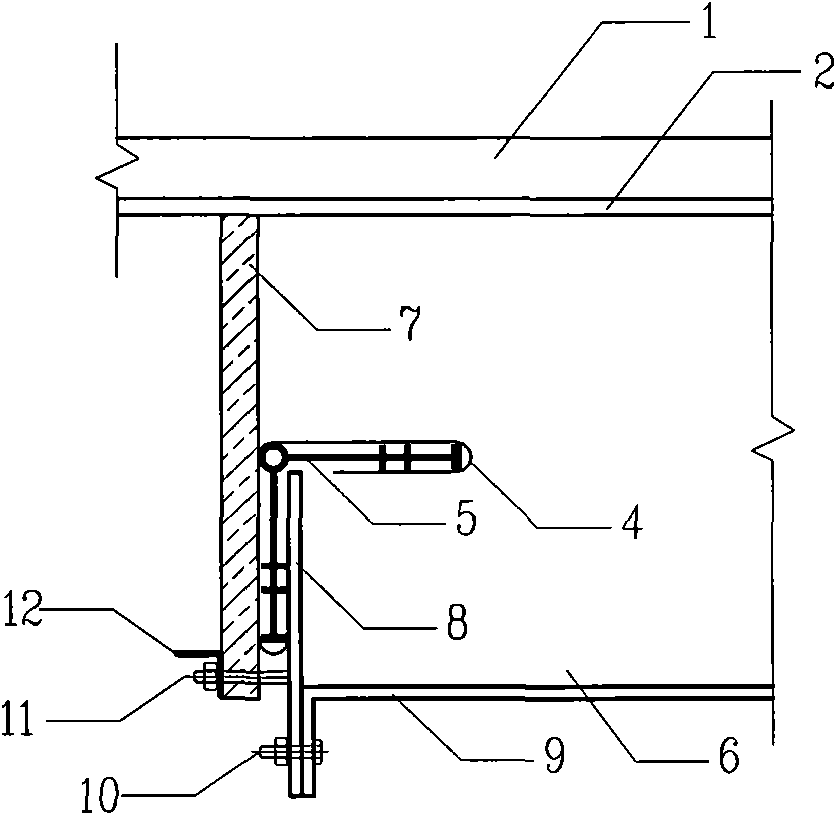

[0015] 1. Combination structure of end steel and wood formwork

[0016] The end steel formwork 8 is cut from a 10mm thick steel plate, the formwork width is 40cm, and the contour size of the arc is determined according to the clearance size of the tunnel design. For easy assembly, the formwork is divided into blocks and numbered, and holes are drilled at 10cm inside the formwork along the contour line of the trolley, with a hole distance of 50cm, corresponding to the holes drilled on the formwork of the trolley, the formwork is assembled according to the number and the steel formwork is fixed with M20 bolts on the trolley. Stagger the fastening bolts of the steel formwork, and weld the screw on the end steel formwork along the contour line of the trolley to the end steel formwork, with a circumferential distance of 50cm and a screw length of 10cm. Drill two holes on the 1m long 75 angle steel, the hole spacing is 50cm, and the wood formwork fastening bolts are pressed against...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com