Burner for main burning furnace of sulfur recovery unit

A sulfur recovery and burner technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of slow mixing process, combustion stability and temperature field distribution, slow temperature rise of main jet, etc., to achieve Effects of improving combustion stability, increasing total sulfur generation rate, and reducing pressure drop loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

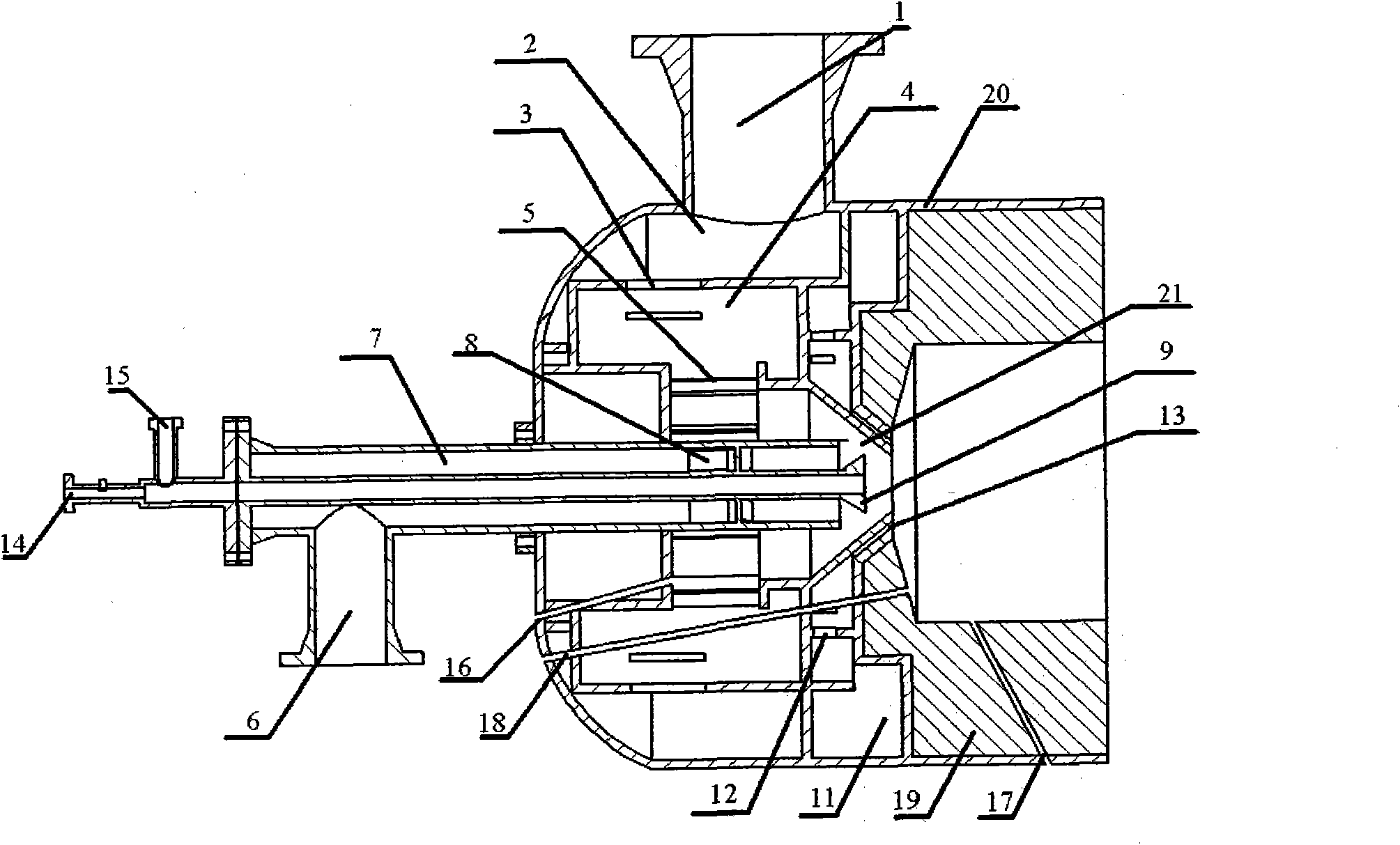

[0018] The present invention will be further described below with reference to the accompanying drawings and embodiments.

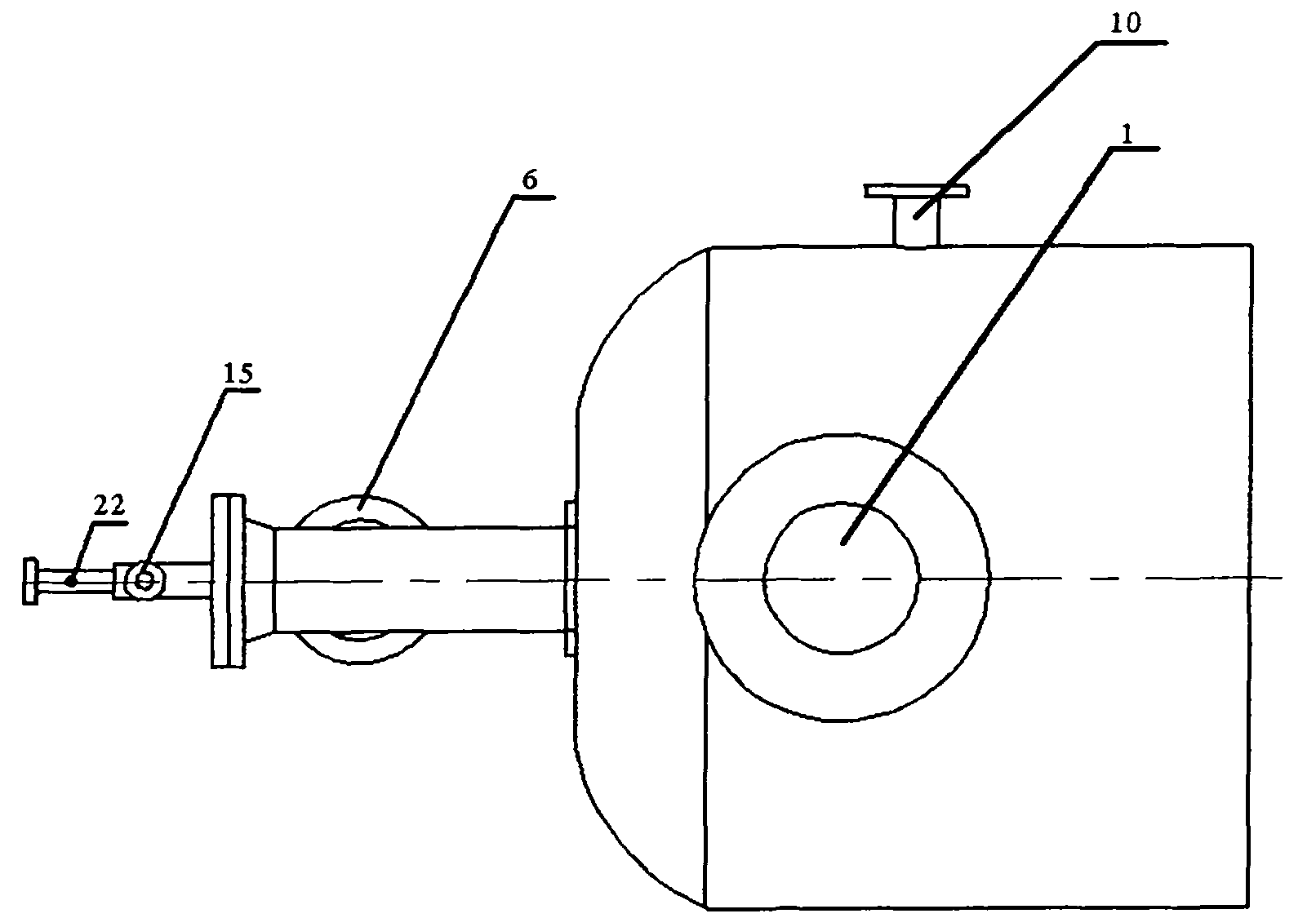

[0019] like figure 1 , figure 2 shown.

[0020] The burner of the present invention is divided into three parts: an air swirl device, an acid gas inlet device and an accessory device of the burner. The following are respectively expressed as follows:

[0021] 1. Air swirl device

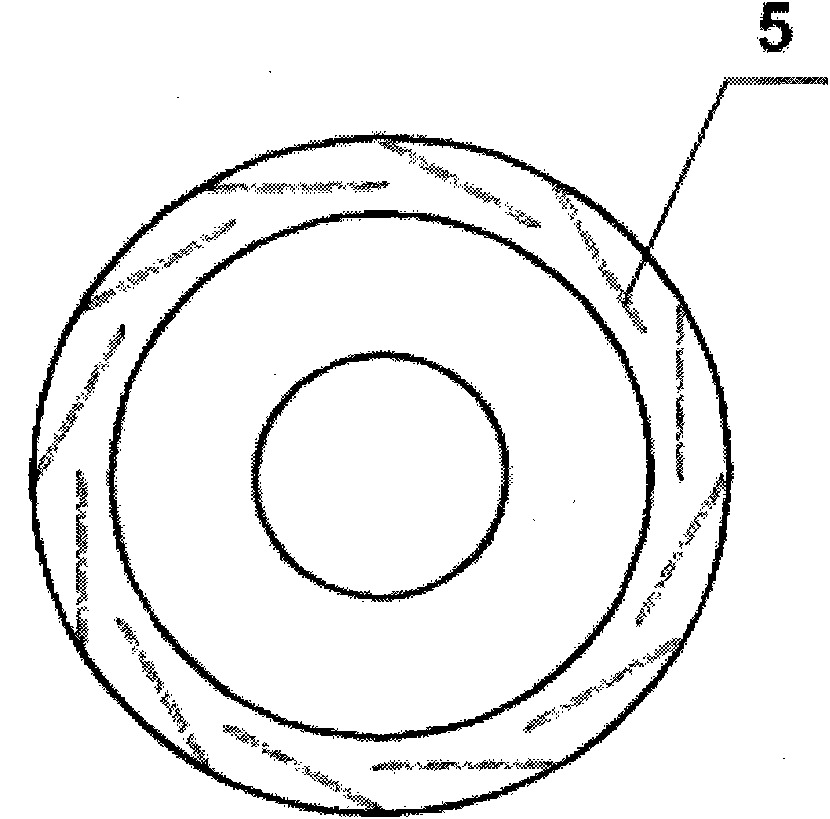

[0022] The air swirling device mainly includes an air inlet 1, an air chamber cavity 2, an air chamber perforated plate 3, an air chamber chamber 4, and an air guide vane 5. Its main function is to realize an air jet with high swirling characteristics. The air is introduced into the air inlet 1 by the blower, and is blocked by the perforated plate 3 of the air chamber, and the air quickly fills the entire cavity 2 of the air chamber. Afterwards, it enters the air chamber cavity 4 relatively uniformly through the air chamber perforated plate 3 . After the air enters the ai...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap