Method for calibrating distance between lens fiber node and rotation axis of uniaxial tracking frame

A single-axis tracking and rotating axis technology, applied in the direction of optical devices, measuring devices, instruments, etc., can solve problems such as large errors and measurement system errors, and achieve the effects of improving measurement accuracy, high calibration accuracy, and great use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

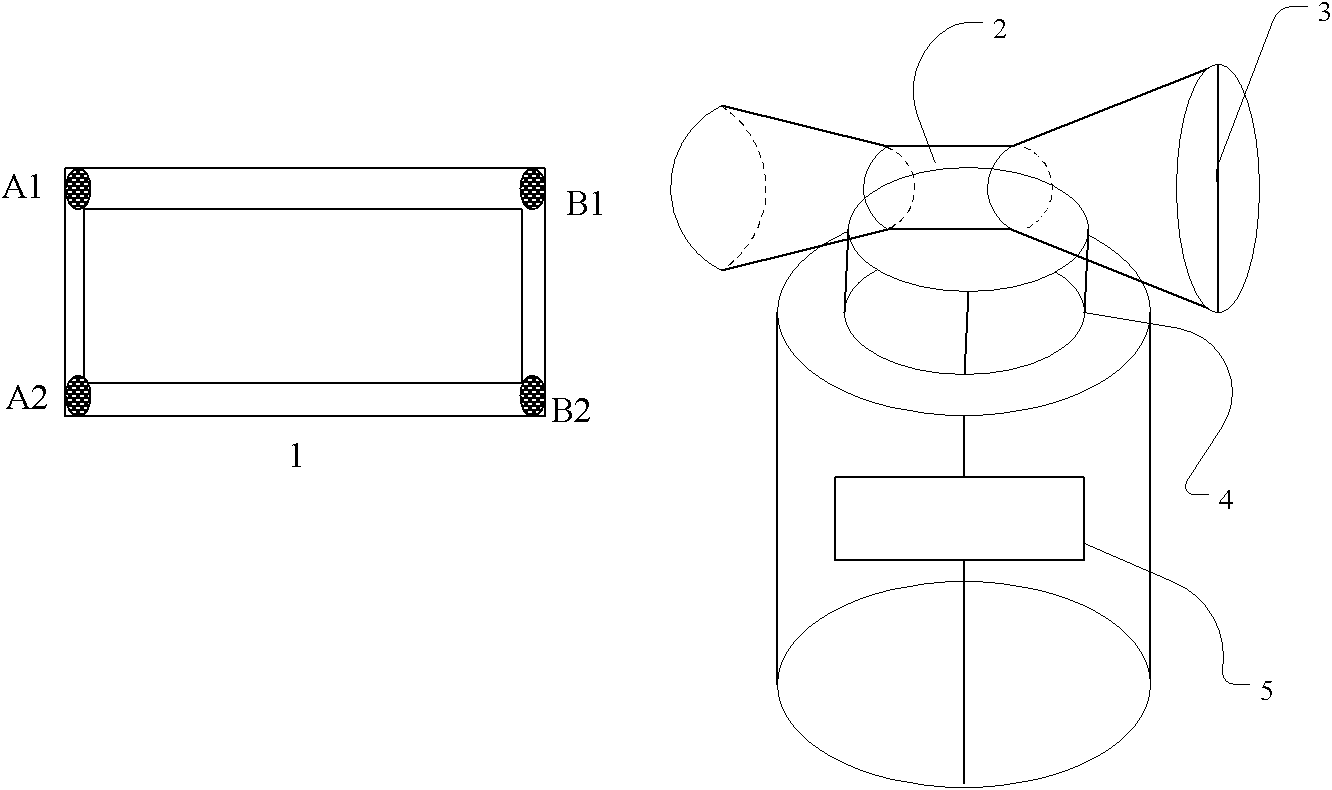

[0018] Such as figure 1 Shown, the photoelectric measurement system that the present invention adopts is mainly made up of laser target frame 1, optical lens 2, linear array CCD 3, turntable 4, photoelectric encoder 5; established measurement system.

[0019] The method of the present invention to calibrate the distance between the optical node of the lens and the rotation axis of the single-axis tracking frame is as follows:

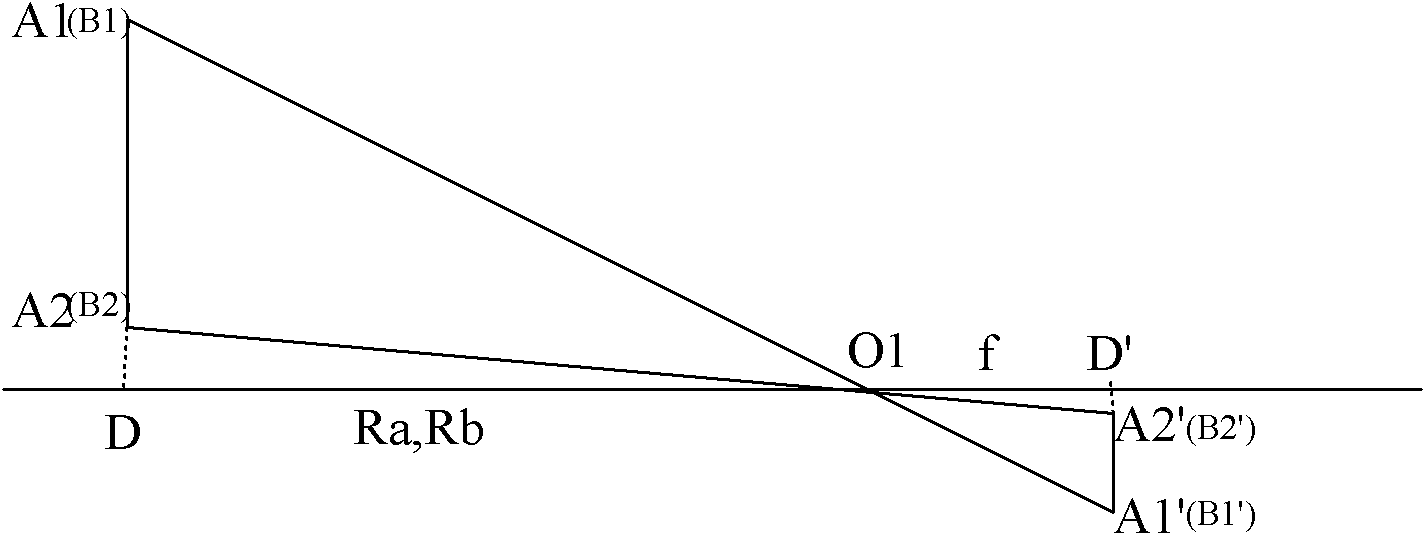

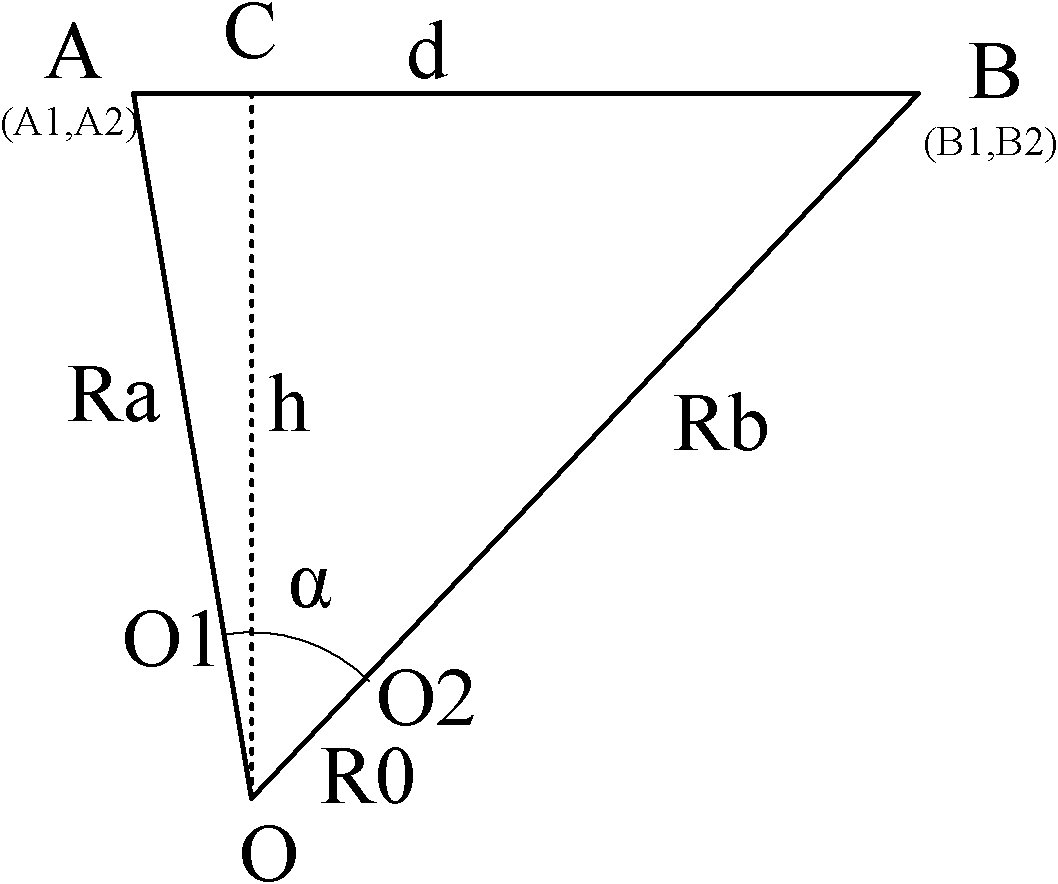

[0020] 1) The linear array CCD 3 is installed on the image plane of the optical lens 2, because the table top of the turntable 4 and the optical lens 2 are all circular, the optical axis of the optical lens 2 and the optical axis of the turntable 4 can be arranged according to symmetry. The axes of rotation intersect at one point; according to the theory of optical imaging, a mathematical model for calculating the distance between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com