Online test system of friction stir welding

A friction stir welding and online testing technology, applied in signal transmission systems, electrical signal transmission systems, measuring devices, etc., can solve problems such as low efficiency, cumbersome operation, complex structure, etc., and achieve simple operation, simple operation, and accurate and simple measurement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0022] like Figure 1-2 shown.

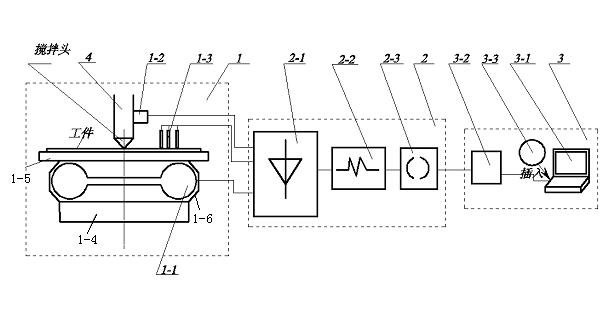

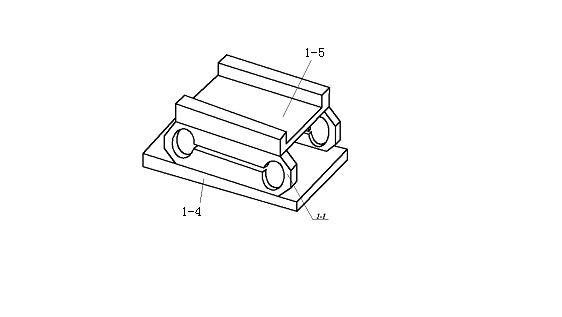

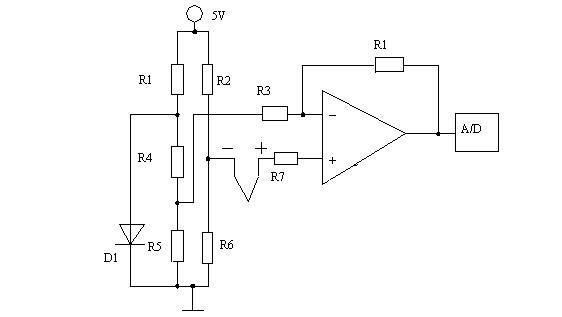

[0023] A friction stir welding online test system is characterized in that it is mainly composed of a signal induction platform 1, a signal conditioning system 2 and a data acquisition system 3, such as figure 1 As shown, the signal sensing platform 1 includes two symmetrically arranged force-measuring octagonal rings 1-1 (such as figure 2 ), a vibration sensor 1-2 and a temperature sensor 1-3, two force-measuring octagonal rings 1-1 are symmetrically fixed on opposite sides of the base 1-4, and each force-measuring octagonal ring 1-1 is provided with a bell Shaped horizontal through hole 1-6, that is, there is a sub-bell-shaped hole on the longitudinal section surface of each force-measuring octagonal ring 1-1 (the round holes at both ends are connected through a flat hole), and the force-measuring octagonal ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com