Method of differentiating martensite in cast ferrite stainless steel and calculating martensite -phase contents

A martensite phase and ferrite technology, applied in the field of identifying martensite in as-cast ferritic stainless steel and calculating martensite phase content, can solve the problems of difficult hardness, inaccurate data, and complicated operation. , to achieve the effect of accurate experimental means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

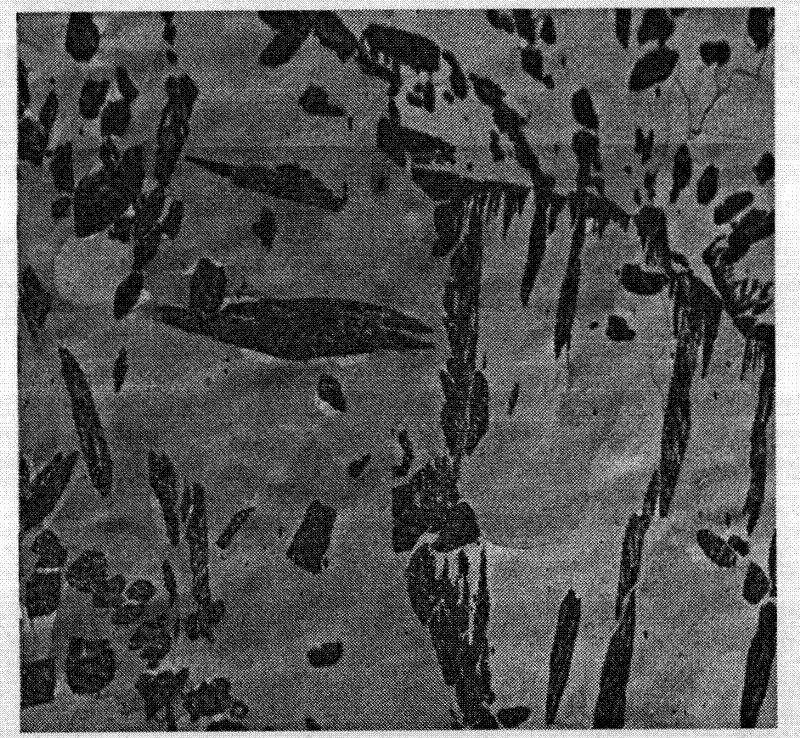

[0033] To use the present invention to calculate the proportion of martensite, first select a sample to cut, grind the sample on a sample grinding machine, and grind from No. 200 sandpaper to No. 1200 sandpaper successively. Then polish the sample on a polishing machine, select a polishing paste with a particle size of about 1 μm, and polish it for about 10 minutes. No obvious scratches can be observed on the surface of the sample under a metallographic microscope at 50 times.

[0034] Then carry out stress-relief electrolytic polishing. The polishing solution uses an alcohol solution containing 5%-10% perchloric acid. During the polishing process, the sample is gently shaken to make the electrolytic product leave the sample. After the polishing is completed, the polished surface presents a bright silver color. No attachments. ;

[0035] After the stress relief electrolytic polishing is completed, quickly wash it in alcohol, and finally dry it with a hair dryer on a cool wind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com