Large-package zero-twist winding machine

A winder and large package technology, applied in the field of winder, can solve problems such as insufficient operation control, inability to achieve digitalization, electronicization, and inability to realize precise control of equipment, so as to achieve high stability and ensure concentricity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

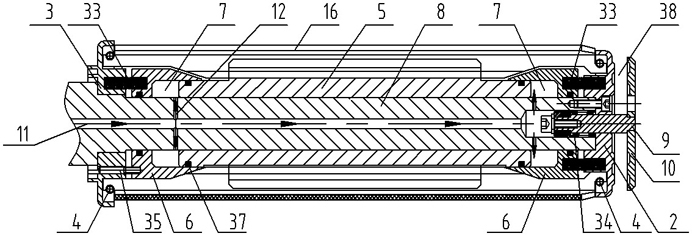

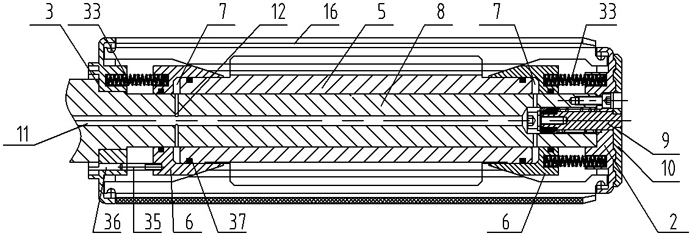

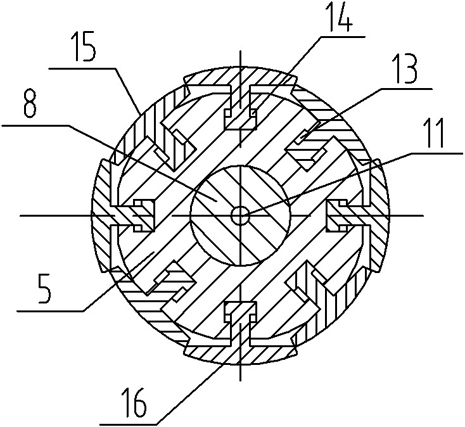

[0030] Embodiment: the large package twistless winder of this example comprises frame 1, and frame is provided with head yarn clamping device, and machine head yarn clamping device is connected on the yarn ball tension curve control device, and yarn ball tension curve control The device is connected to the traverse compression curve control device.

[0031] Machine head clamping device: such as figure 1 , figure 2 , there is a front cover 2 and a rear cover 3, an expansion piece is arranged between the front cover and the back cover, the expansion piece is connected with a tension spring 4, a sleeve 5 is arranged inside the expansion piece, and taper sleeves are provided at both ends of the sleeve 6. A compression spring 33 is connected between the taper sleeve, the front cover and the rear cover. The taper sleeve is connected with a guide rod 35, and the back cover is provided with a guide groove 36 that allows the guide rod to slide. There is an air cavity 7 between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com