Surface treatment process of reddened copper foil for high-grade FR-4 copper-clad plate

A surface treatment, 1.FR-4 technology, applied in metal material coating process, secondary treatment of printed circuit, improvement of metal adhesion of insulating substrate, etc., to achieve excellent chemical resistance and etching, excellent anti-plating layer Diffusion performance, excellent anti-room temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

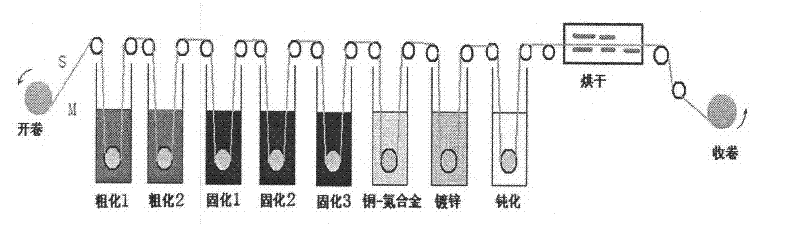

[0035] The surface treatment process of red copper foil for high-grade FR-4 copper clad laminates, the specific steps are as follows:

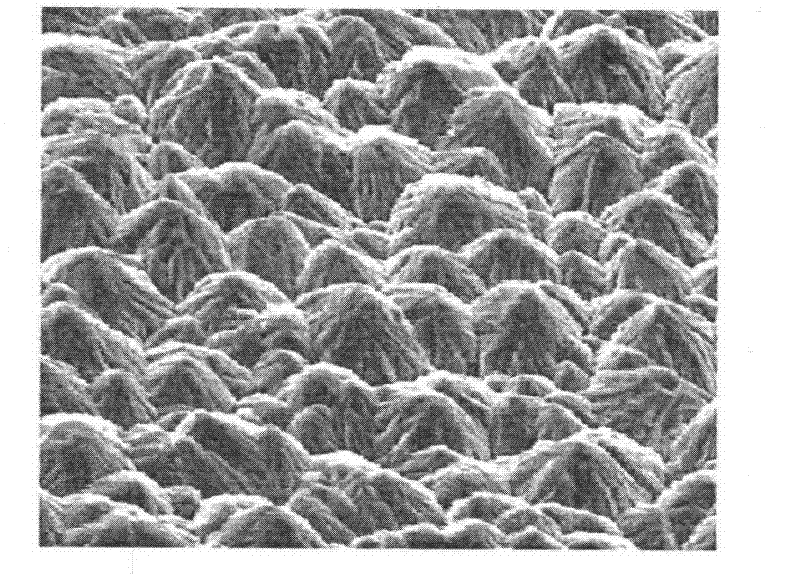

[0036] 1. Coarsening: mix and dissolve cathode copper, concentrated sulfuric acid, soft water, and steam to form copper sulfate solution, then add additive A, mix well, pump it into the roughening tank for electroplating; among them, Cu 2+ 10g / L,H 2 SO 4 80g / L, the additive A is gum arabic, the concentration is 8.5ppm, the temperature is 25°C, and the current density is 20A / dm 2 .

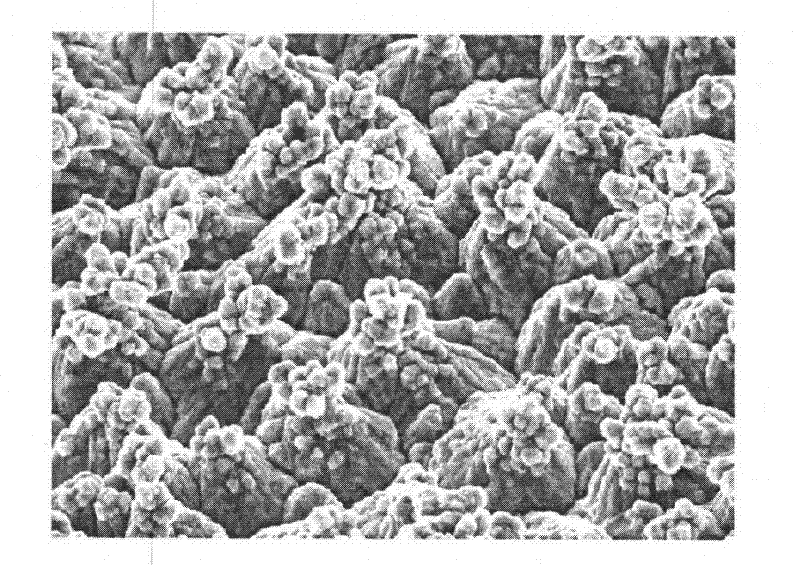

[0037] 2. Curing: Mix and dissolve cathode copper, concentrated sulfuric acid, soft water, and steam to generate a copper sulfate solution, which is pumped into the curing tank for electroplating; where Cu 2+ 50g / L, H 2 SO 4 80g / L, temperature is 35℃, current density is 20A / dm 2 .

[0038] 3. Copper-nitrogen alloy: mix and dissolve cathode copper, concentrated sulfuric acid, soft water, and steam to form a copper sulfate solution, then add additive T, mix...

Embodiment 2

[0044] The difference between this embodiment and embodiment 1 is that

[0045] 1. Coarsening: Cu 2+ 30g / L, H 2 SO 4 200g / L, temperature is 50℃, current density is 35A / dm 2 , Additive A selects hydroxyethyl cellulose with a concentration of 5.4ppm.

[0046] 2. Curing: Cu 2+ 100g / L,H 2 SO 4 200g / L, temperature is 55℃, current density is 35A / dm 2 .

[0047] 3. Copper-nitrogen alloy: Cu 2+ 20g / L, H 2 SO 4 200g / L, temperature is 50℃, current density is 20A / dm 2 , Additive T 500ppm, additive T selects acridine orange for use.

[0048] 4. Galvanized: K 4 P 2 o 7 300g / L, Zn 2+ 10g / L, PH 11, temperature 50℃, current density 1.5A / dm 2 , Additive M is tartaric acid, the concentration is 2.3g / L.

[0049] 5. Passivation: potassium chromate 10g / L, pH 12, temperature 50°C, current density 8.0A / dm 2 .

[0050] 6. Coupling agent spraying: silane coupling agent volume percentage concentration 5%, temperature 40°C.

Embodiment 3

[0052] The difference between this embodiment and embodiment 1 is that

[0053] 1. Coarsening: Cu 2+ 20g / L, H 2 SO 4 140g / L, temperature is 40℃, current density is 30A / dm 2 , Additive A is selected from propenyl thiourea, the concentration is 2.0ppm.

[0054] 2. Curing: Cu 2+ 75g / L, H 2 SO 4 140g / L, temperature is 45°C, current density is 27A / dm 2 .

[0055] 3. Copper-nitrogen alloy: Cu 2+ 13g / L,H 2 SO 4 140g / L, temperature is 40℃, current density is 11A / dm 2 , Additive T 255PPM, additive T selects the mixture of phenazine and 5-hydroxymethyl pyrimidine according to mass ratio 2:1.

[0056] 4. Galvanized: K 4 P 2 o 7 220g / L, Zn 2+ 6g / L, PH 10, temperature 35℃, current density 1A / dm 2 , Additive M is sodium dihydrogen phosphate, the concentration is 8.2g / L.

[0057] 5. Passivation: Potassium chromate 6g / L, pH 10, temperature 40°C, current density 5.0A / dm 2 .

[0058] 6. Coupling agent spraying: silane coupling agent volume percentage concentration 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com