Work duplex-head grinding apparatus, and work duplex-head grinding method

A technology of double-sided grinding and workpiece, applied in the field of double-sided grinding device of workpiece and double-sided grinding of workpiece, can solve the problems of large deviation, exceeding 0.2μm, etc., and achieve the effect of small deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

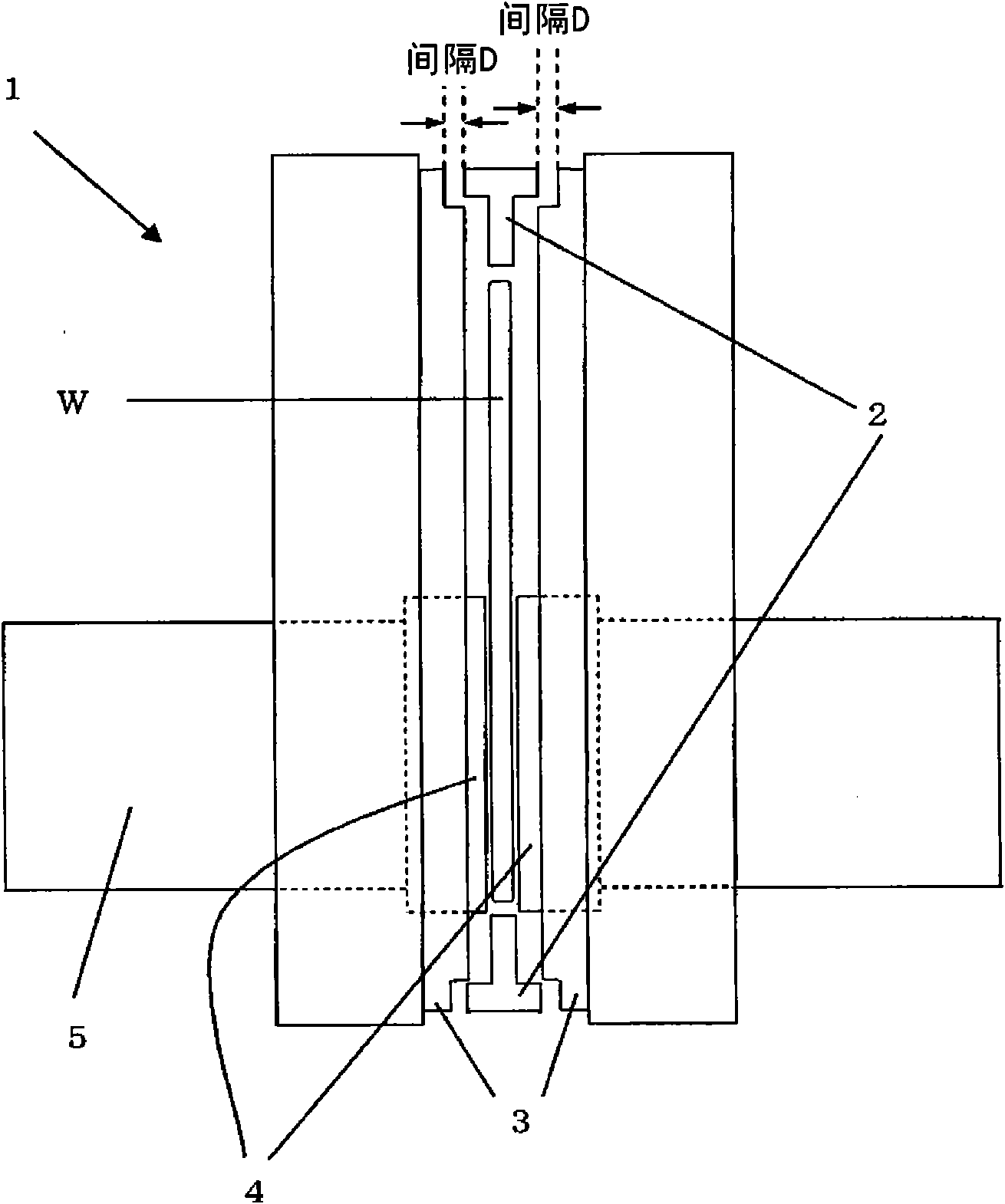

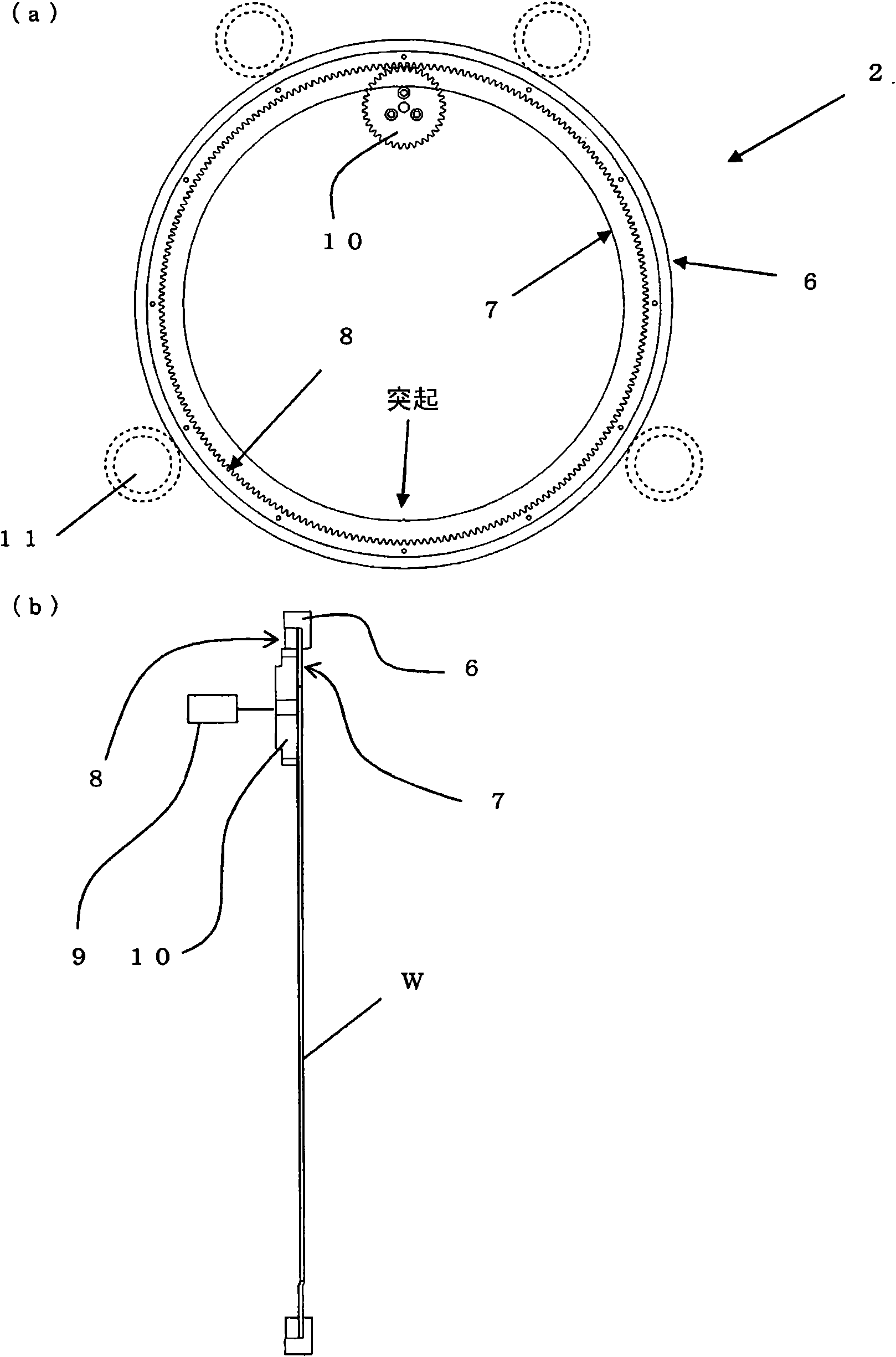

[0107] use figure 1 The double-sided grinding device 1 for workpieces of the present invention shown in , performs double-sided grinding of workpieces (silicon chips with a diameter of 300 mm) according to the double-sided grinding method of the present invention.

[0108] The ring portion of the workpiece holder is made of alumina ceramics. The flatness of the workpiece holder was 5 μm, the parallelism was 5 μm, and the flatness of the hydrostatic support member was 15 μm.

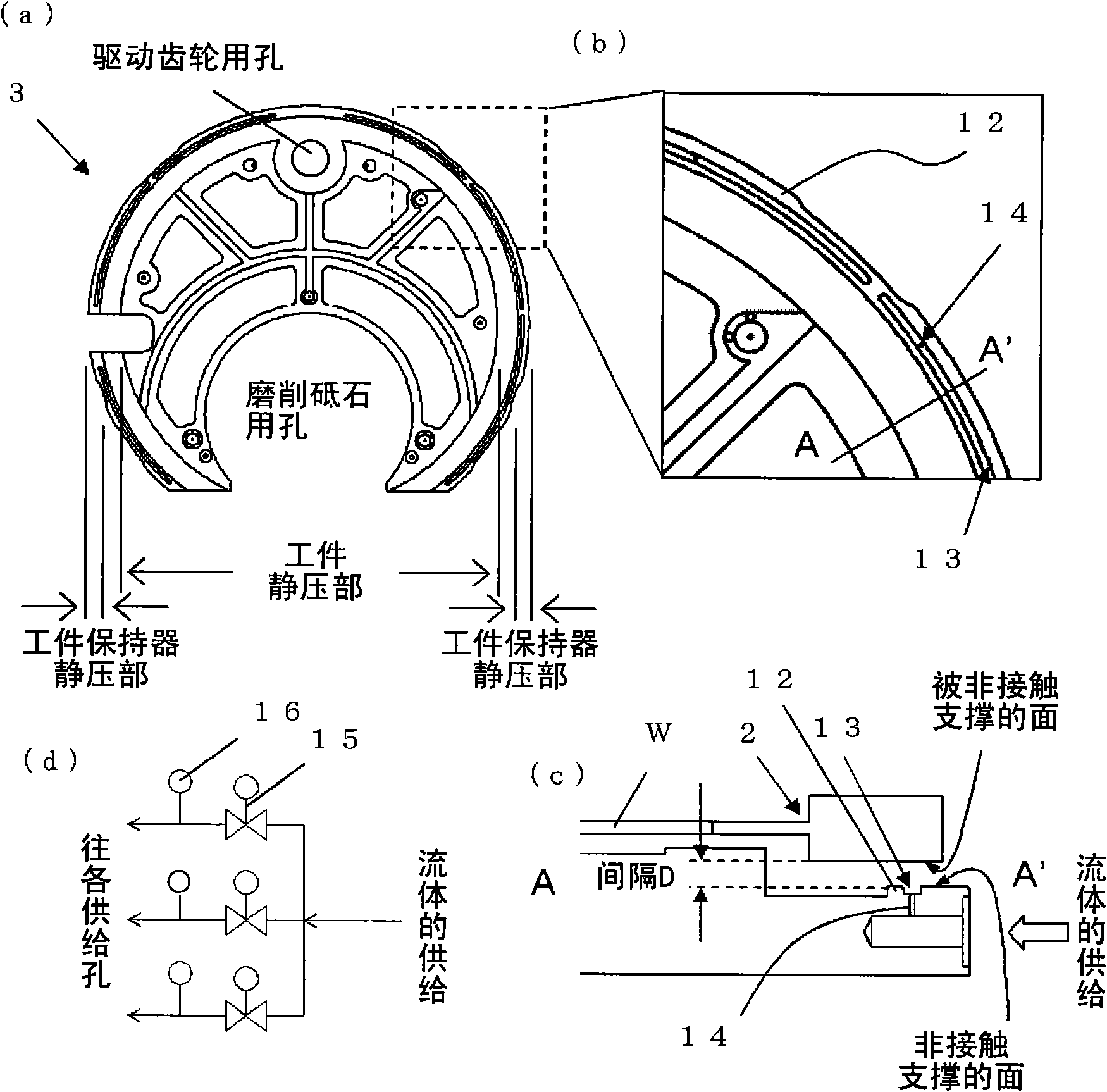

[0109] The distance between the workpiece holder and the static pressure support member was set to 30 μm. In addition, water was supplied from the supply hole of the static pressure support member, and the workpiece holder was supported non-contact by a static pressure of 0.6 MPa. Furthermore, SD#3000 whetstone and SD#8000 whetstone (vitrified sintered whetstone manufactured by Japan United Materials Co., Ltd. (A.L.M.T)) composed of diamond grains with an average particle size of 1 μm or less and vitri...

Embodiment 2

[0117] (Example 2, Comparative Example 2)

[0118] A workpiece (a silicon chip with a diameter of 300 mm) was ground in the same manner as in Example 1, except that SD#8000 whetstone was used as the whetstone, and the setting of the static pressure value by water was changed.

[0119] The static pressure generated by water was 0.3Mpa, 0.8Mpa, 1.0MPa (the above is Example 2), and 0.2MPa (Comparative Example 2).

[0120] Figure 7 Indicates the result based on the static pressure value generated by water and the approximate nano-morphology of the ground workpiece. In addition, the value of the approximate nanomorphology of Example 1 is also shown as a reference (value in hydrostatic pressure 0.6 Mpa).

[0121] In Comparative Example 2, the approximate nano-topography is as large as 0.8 μm, and in Example 2, all are suppressed below 0.2 μm.

[0122] In this way, if the static pressure value is smaller than 0.3 MPa, the approximate nano-morphology becomes remarkably large, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com