Novel static mixer for gas mixing

A static mixer, gas mixing technology, applied in the direction of fluid mixer, gas and gas/vapor mixing, mixer, etc., can solve the problem of unsatisfactory mixing effect, etc., to prolong the residence time, improve the mixing rate, and improve the turbulent flow. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manner of the present invention is described with reference to the accompanying drawings.

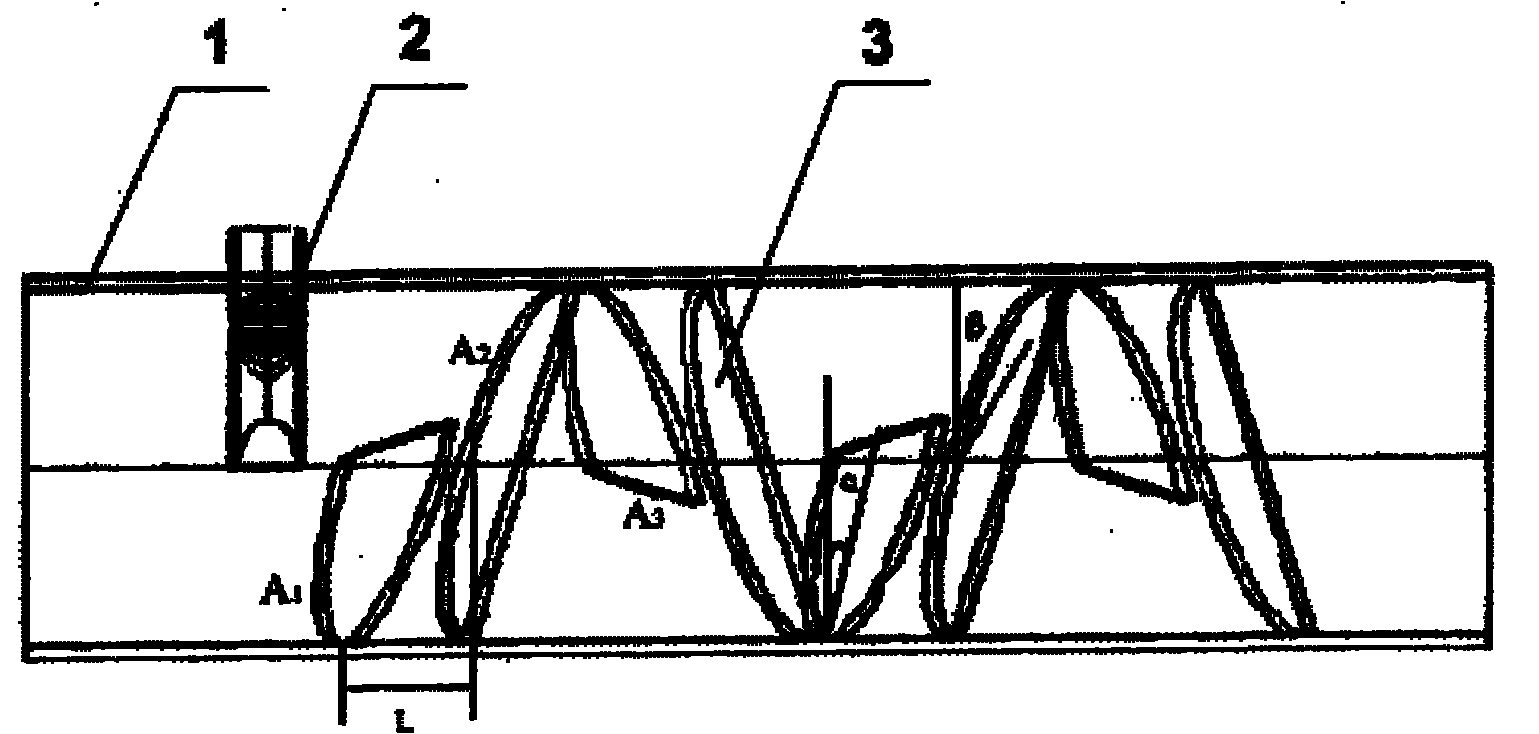

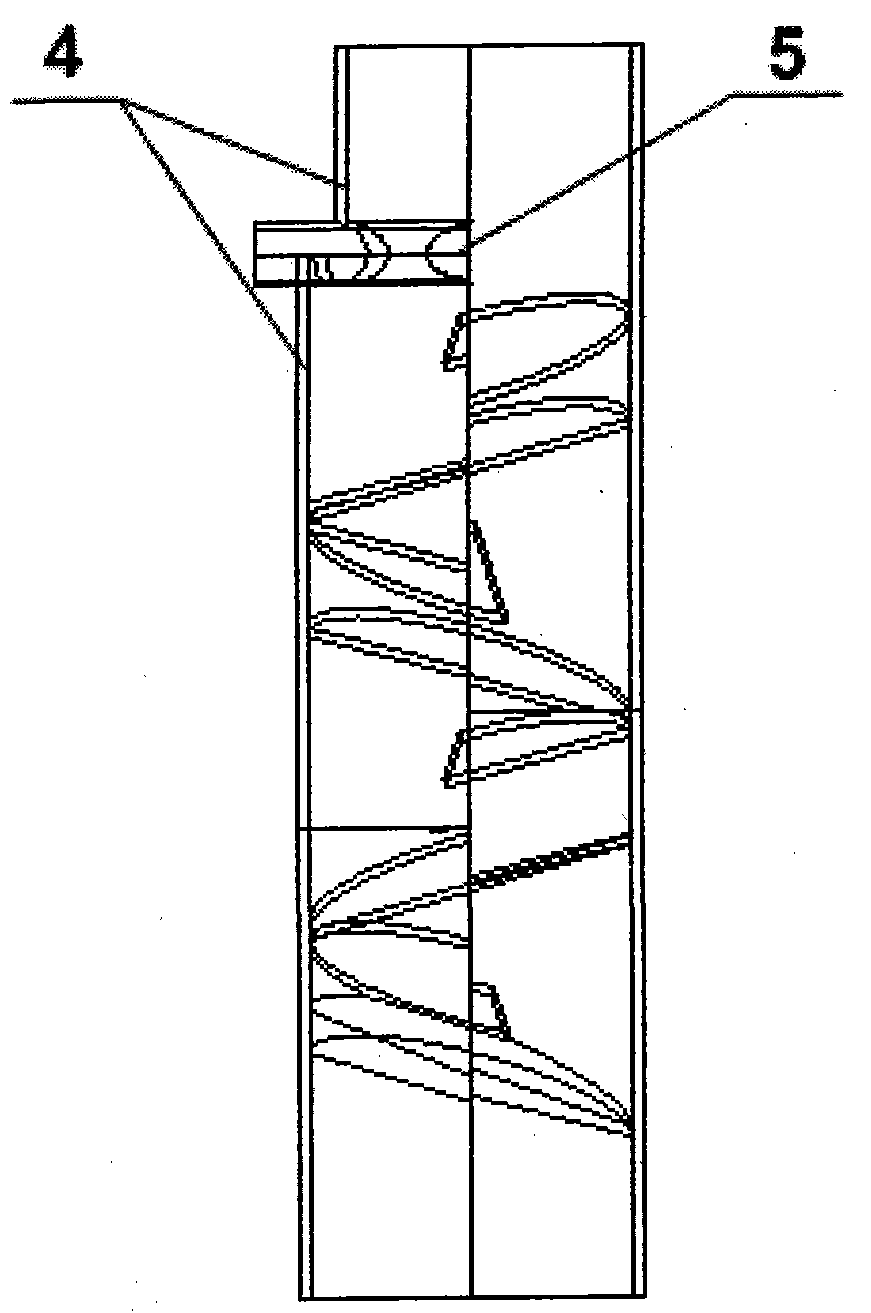

[0019] Such as figure 1 , 2 , 3, 4 shown.

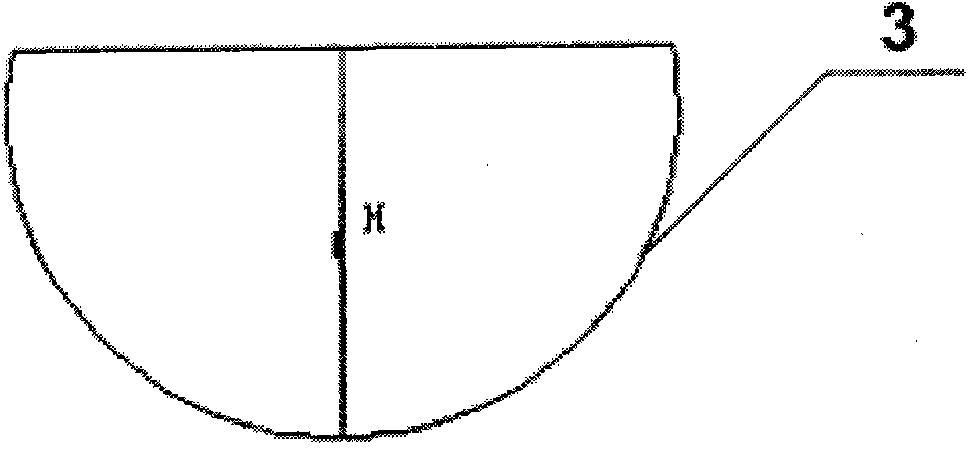

[0020] The design length of the mixer is 1200mm, the inner diameter of the main pipe is 300mm, the inner diameter of the auxiliary pipe is 50mm, the wall thickness is 10mm, α is 18°, β is 18°, the blade axial distance L is 100mm, and the blade height H is 160mm. The two gases enter from the main pipe 1 and the auxiliary pipe 2 respectively, and the two gases start to mix at the outlet of the auxiliary pipe 2, and then the gas after preliminary mixing flows to the first blade 3, because the blade area is large and has a certain inclination angle- α is the inclination angle of the blade, β is the rotation angle of the blade, and L is the axial spacing of the blade. A part of the mixed gas will flow to the other side of the flow channel. Because the space becomes smaller, the mixed gas is squeezed through, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com